Extruding coating type die head gasket capable of eliminating coating edge effect

An edge-effect, coating-type technology, applied in the field of extrusion-coated die gaskets, can solve problems such as cracking at the edge of the pole piece, lithium deposition at the edge of the pole piece, and high compaction density at the edge of the pole piece, and achieve fluid pressure Stability, high thickness consistency, and the effect of controlling the thickness of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

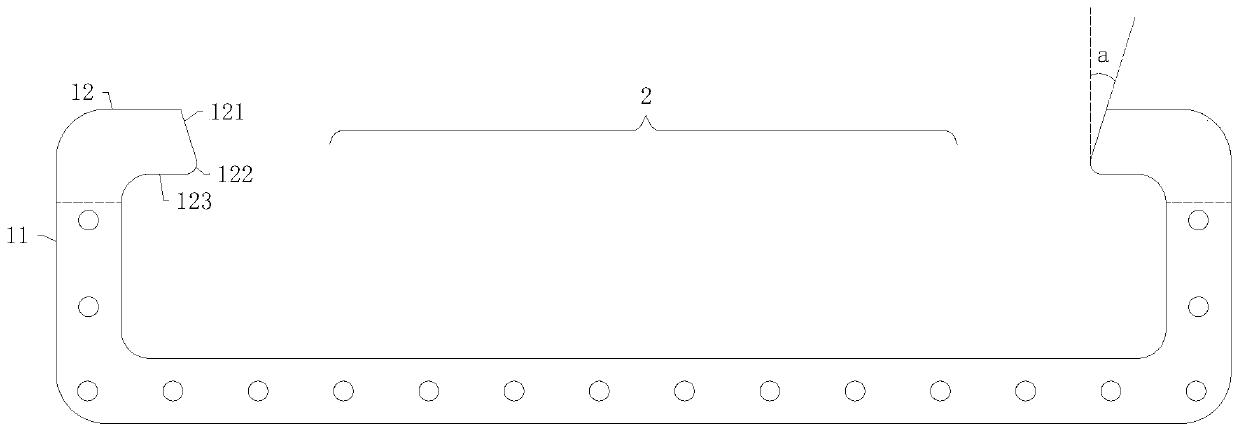

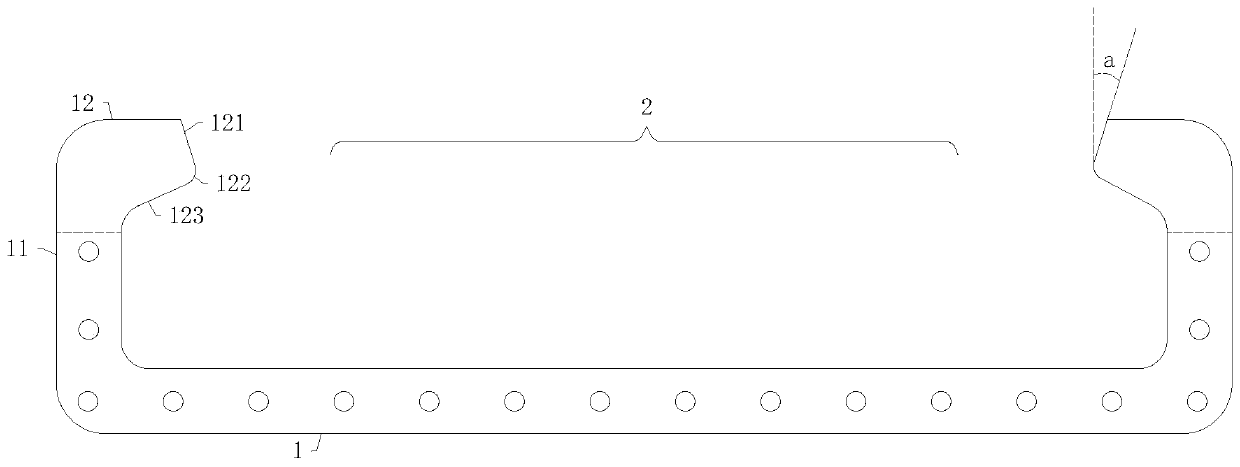

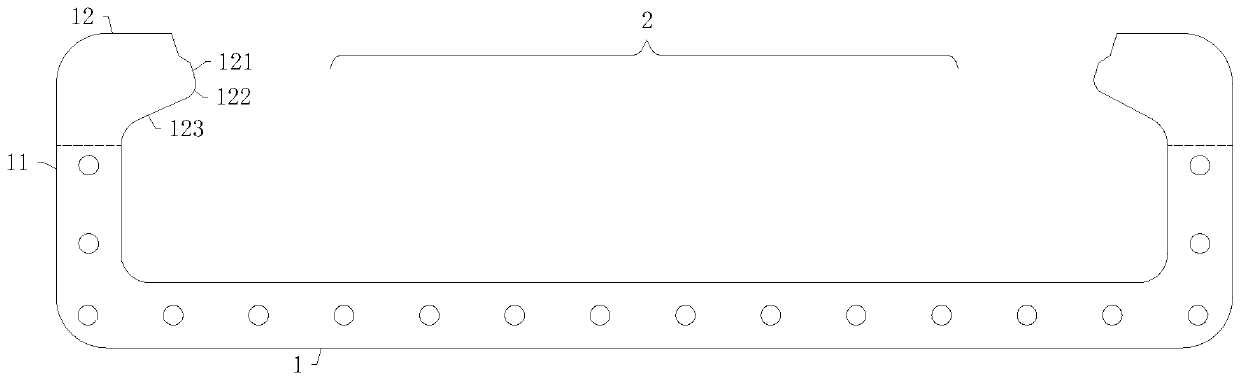

[0041] see Figure 1-5 A kind of extrusion coating type die head gasket that can eliminate coating edge effect, it comprises die head gasket body 1, is provided with outlet 2 in die head gasket body 1, and die head gasket body 1 includes The lower gasket 11 and the upper extension gasket 12 fixed on the left and right upper ends of the lower gasket 11 are U-shaped. Air, steam, water and other weak corrosive media and acid, alkali, salt and other chemical corrosive media corrode, and the service life is improved. The space formed between the inner wall of the lower gasket 11 and the two upper extended gaskets 12 forms the discharge port. 2.

[0042] There are chamfers at the corners of the left and right inner bottom ends of the lower gasket 11 and between the guide surface 123 and the lower part of the inner wall of the upper extension gasket 12, so that the slurry flows between the guide surface 123 and the guide bevel 121. Under the effect of more chamfering, the flow is s...

Embodiment 2

[0047] The guide surface 123 is set as an upwardly inclined structure, and the connection between the guide surface 123 and the guide bevel 121 is provided with a rounded corner portion 122. Under the inclination of the guide surface 123, it is beneficial to guide the slurry to the guide bevel. The angle 121 side moves, and under the action of the rounded corner portion 122, the slurry is guided to flow from the guide surface 123 to the guide bevel 121 side more smoothly and gently, and the flow speed is more uniform.

[0048] The included angle between the plane where the bottom of the guide surface 123 of the inclined structure is located and the horizontal plane is 30-45°, preferably 45°, so that the process of the slurry flowing to the guide bevel 121 through the guide surface 123 is smoother, and the slurry The fluidity is better, which can more effectively eliminate the problem of uneven coating edge thickness.

[0049] The guide bevel 121 is provided with a guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com