Flow guide reinforcement pipe for coffee machine

A technology for enhancing tubes and coffee machines, applied in the direction of hoses, pipes, applications, etc., can solve problems such as increased fluid pressure, leakage or storage, and complex processes, and achieve stable fluid pressure, smooth flow channels in the tube, and simple processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

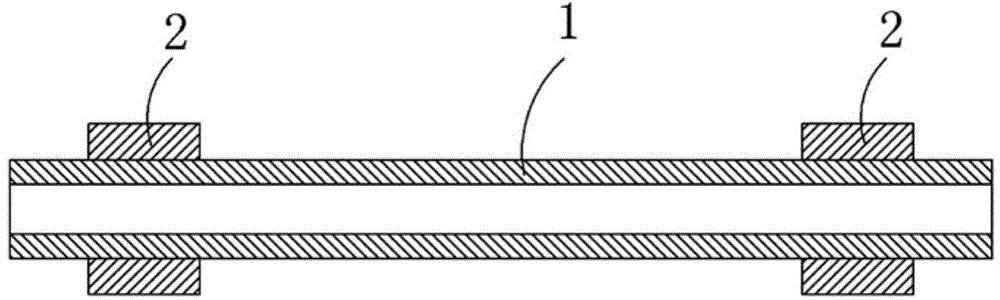

[0025] Such as figure 1 As shown, a diversion enhancement tube for a coffee machine includes a Teflon water pipe 1 and a connector 2. The Teflon water pipe 1 is a single-layer structure, and the Teflon water pipe 1 is a polytetrafluoroethylene layer. The connecting piece 2 is a single-layer structure, and the connecting piece is a polytetrafluoroethylene layer. The Teflon water pipe 1 and the connecting piece 2 are respectively surface treated and fixed with an adhesive.

Embodiment 2

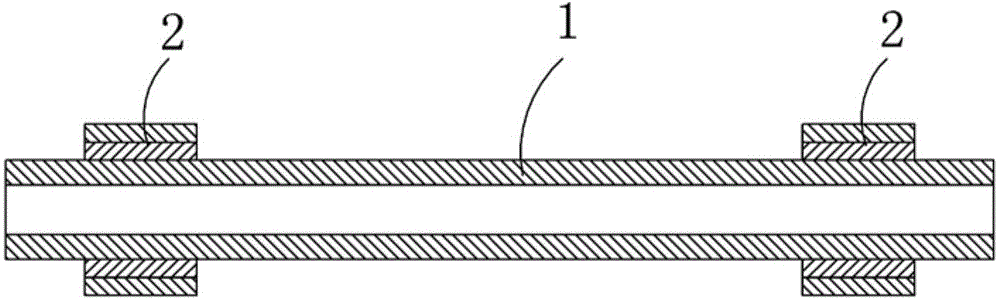

[0027] Such as figure 2 As shown, a diversion enhancement tube for a coffee machine includes a Teflon water pipe 1 and a connector 2. The Teflon water pipe 1 is a single-layer structure, and the Teflon water pipe 1 is a polytetrafluoroethylene layer. The connector 2 described above is a double-layer structure, the outer layer of the connector 2 is a polytetrafluoroethylene layer, and the inner layer of the connector 2 is polychlorotrifluoroethylene (PCTFE), polyfluoroethylene propylene (FEP), tetrafluoroethylene- One of the perfluoroalkoxy vinyl ether copolymers (PFA), after the Teflon water pipe 1 and the connector are assembled according to the design, the inner wall of the connector 2 is welded to the outer wall of the Teflon water pipe 1 by hot air welding fixed.

Embodiment 3

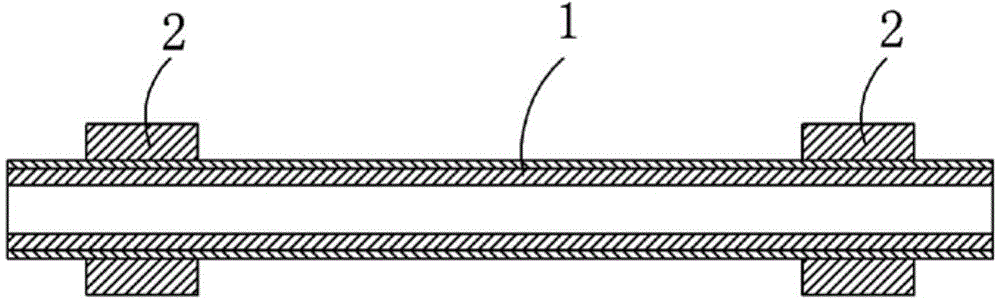

[0029] Such as figure 1 As shown, a diversion enhancement tube for a coffee machine includes a Teflon water pipe 1 and a connector 2. The Teflon water pipe 1 is a single-layer structure, and the Teflon water pipe 1 is a polytetrafluoroethylene layer. The connecting piece 2 is a single-layer structure, and the connecting piece 2 is a modified polytetrafluoroethylene material. The Teflon water pipe 1 and the connecting piece 2 are respectively surface treated and fixed with an adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com