Injection allocation technique for foaming agent

A technology of foaming agent and process, which is applied in the field of foaming agent dispensing process, can solve the problems of increasing vehicle use cost and waste of personnel, and achieve the effects of improving labor efficiency, reducing cost, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

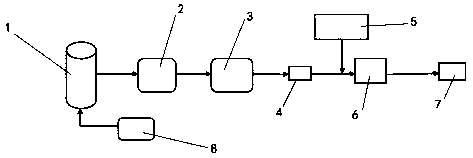

[0023] Embodiment 1 A foam dispensing process, including liquid medicine tanks, filters, metering pumps, pulse dampers, nitrogen injection equipment, foam generators and gas-liquid pipelines for connecting the above-mentioned devices connected in sequence; A drug unloading pump is connected to one side of the liquid medicine tank; a mechanical pressure gauge, a high-pressure flow meter and a cone regulating valve are also connected between the nitrogen injection equipment and the foam generator.

[0024] A foam dispensing process such as figure 1 As shown, the steps are as follows:

[0025] First, heat the medicinal liquid in the tank. After the medicinal liquid reaches 80°C, manually open the valve in the gas-liquid pipeline. After confirming that all the valves on the inlet and outlet pipelines have been opened, then turn on the power supply of the metering pump and start the motor. The medicinal liquid in the body is sucked into the metering pump through the T-type basket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com