Flatness-raised pixel electrode manufacture method

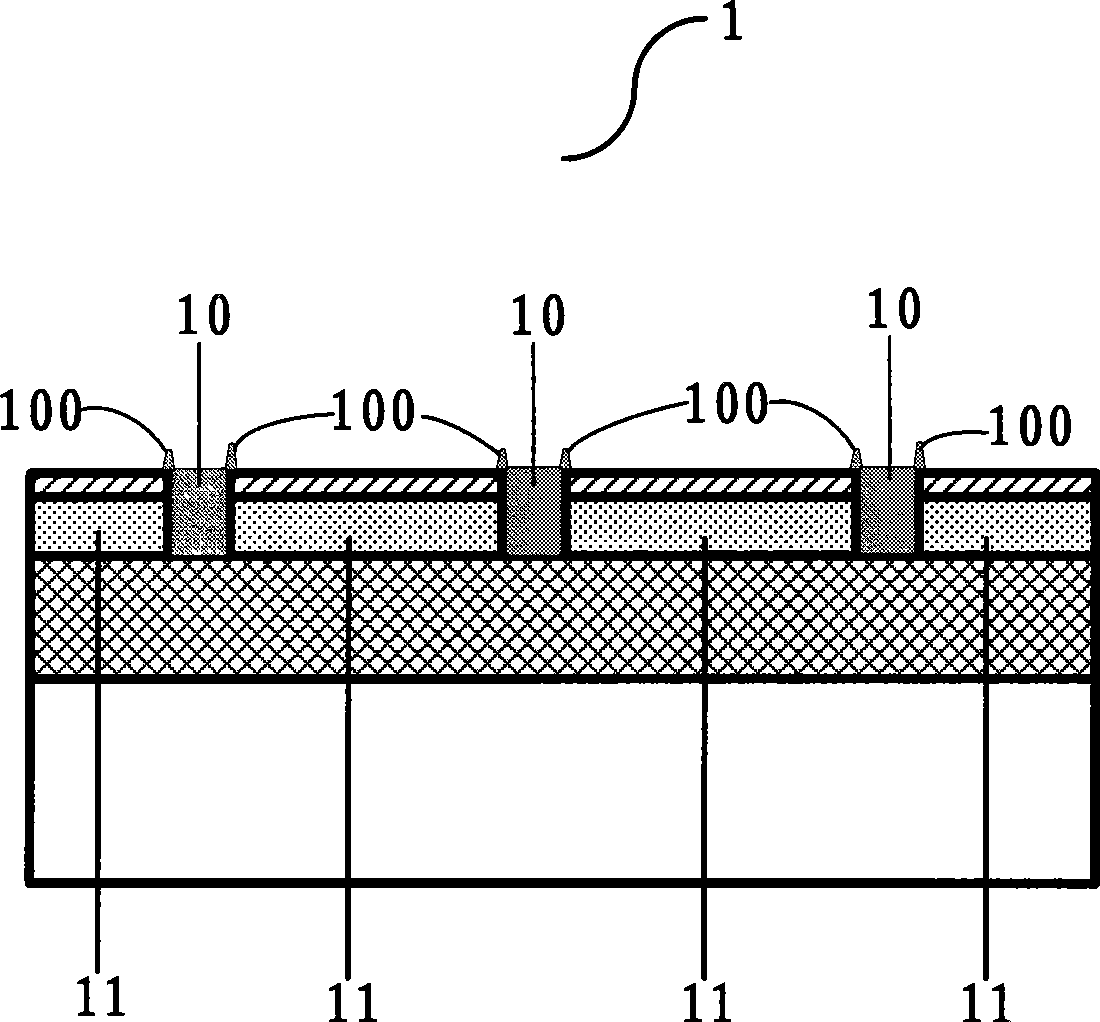

A technology for pixel electrodes and manufacturing methods, which is applied in the field of silicon-based liquid crystal manufacturing, can solve problems such as uneven thickness and inconsistency of liquid crystals, and achieve the effects of improved display contrast, improved performance, and improved thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

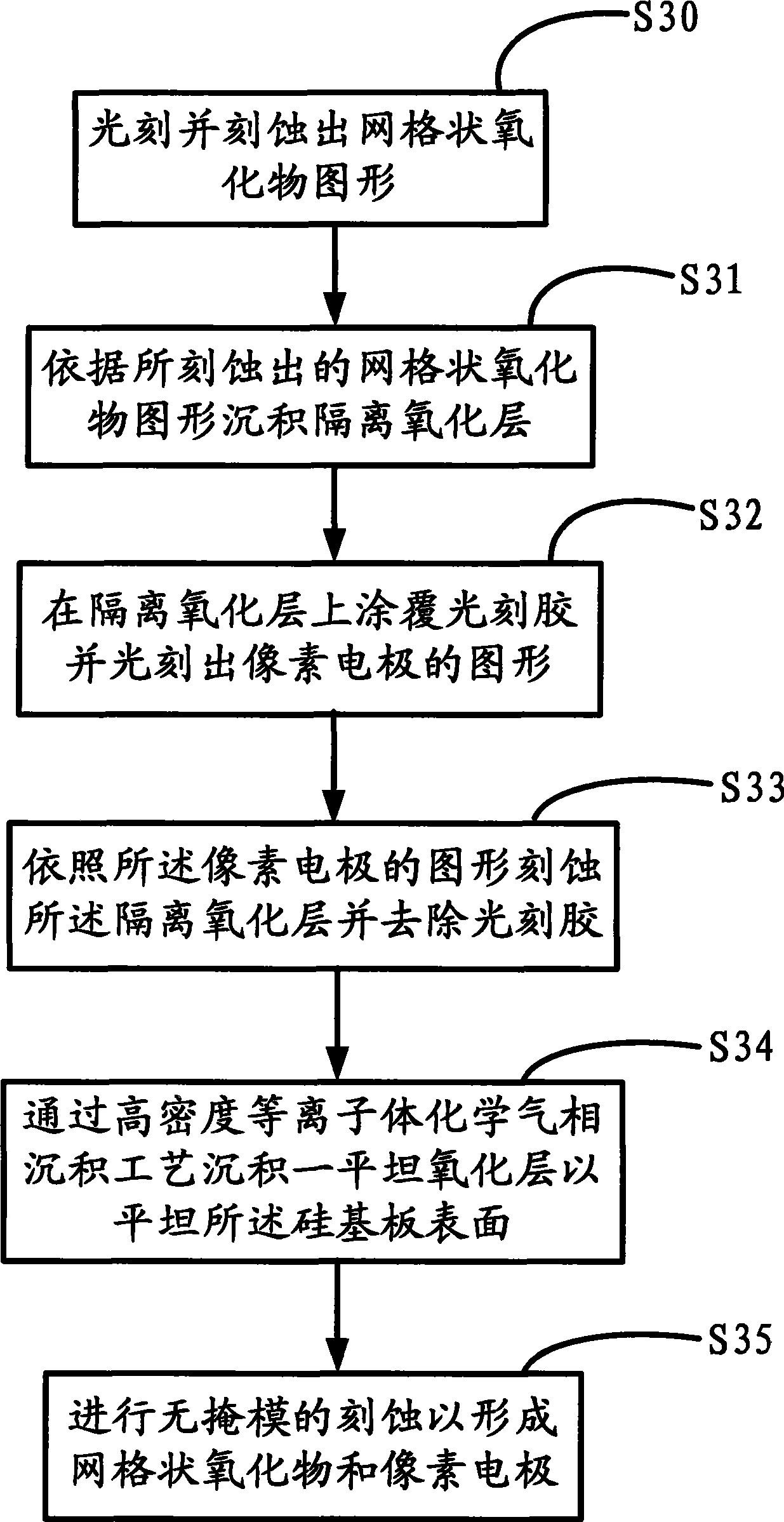

[0020] The method for manufacturing the pixel electrode that can improve the flatness of the present invention will be further described in detail below.

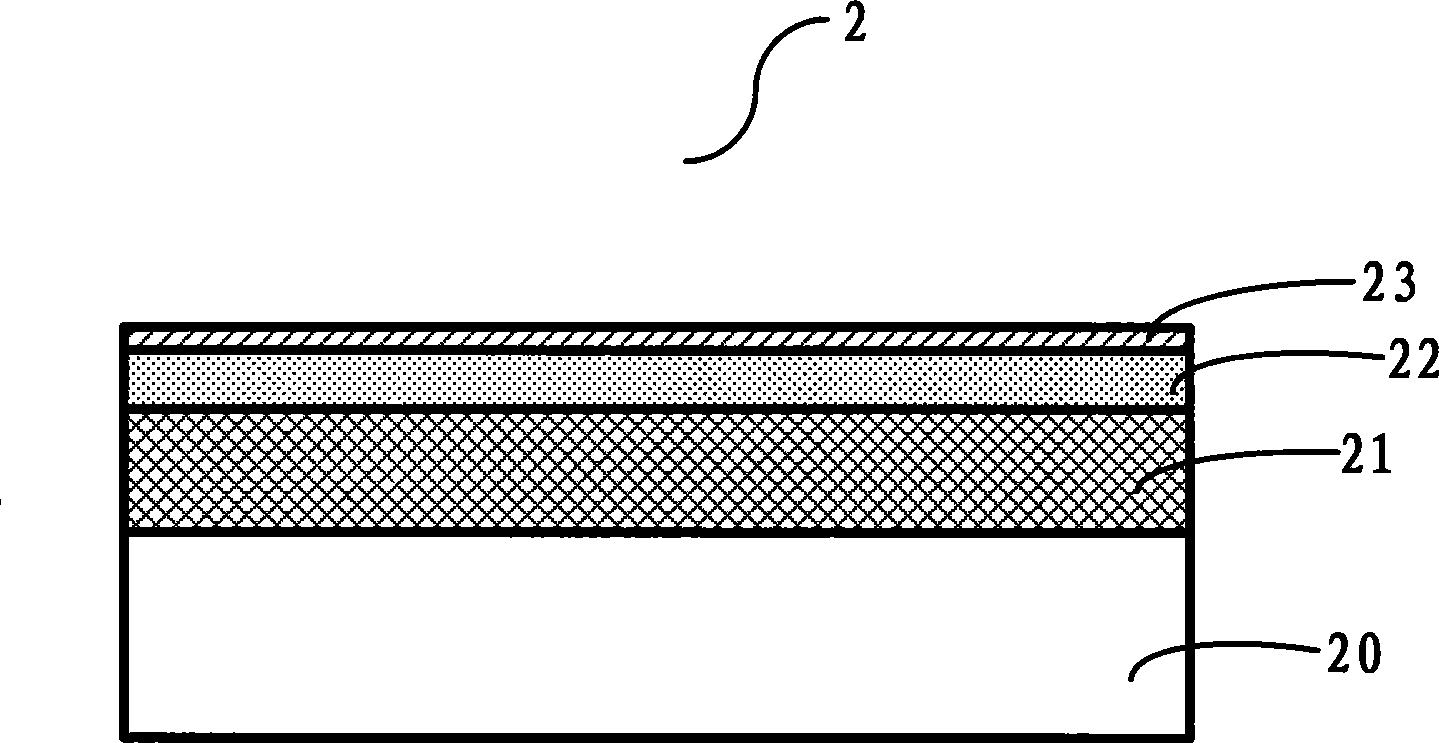

[0021] see figure 2 The pixel electrode in the pixel electrode manufacturing method that can improve the flatness of the present invention is fabricated on the silicon substrate 2, the silicon substrate 2 has a control circuit 20, and an interlayer insulating layer 21 stacked on the control circuit 20 in sequence , top metal layer 22 and protective oxide layer 23 . In this embodiment, the control circuit 20 is composed of MOS tubes, and the internal components of the control circuit 20 are not described in detail here, and the interlayer insulating layer 21 is made of borophosphosilicate glass (Boro-phospho-silicate glass). silicate Glass, BPSG), the top metal layer 22 is the fourth metal layer and it is aluminum, and the protective oxide layer 23 is made by atmospheric radio frequency cold plasma (TEOS) process.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com