Fluorescent powder color wheel and manufacturing method thereof

A technology for fluorescent pink wheels and manufacturing methods, which is applied in the field of fluorescent pink wheels and their production, which can solve the problems of optical path design limitations, high production costs, inflexibility, etc., to reduce the difficulty of the production process, improve functional limitations, and increase flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

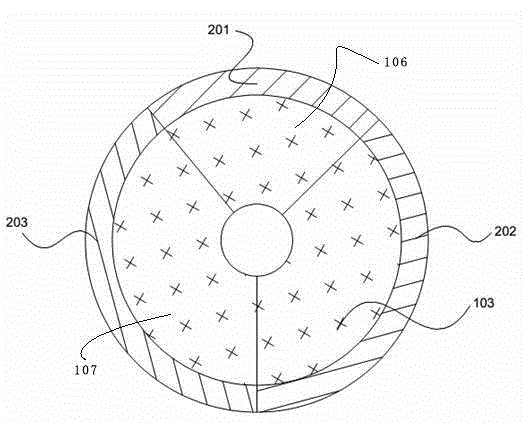

[0040] figure 1 Shown is Example 1 of the present invention, which is assembled from three aluminum substrate fans with a silver-coated film with a thickness of 0.5mm, and red, yellow, A fluorescent pink wheel layer assembled after green three different fluorescent pink segments. Three pieces of aluminum substrate fans 103, 106, 107 with different angles but with a sum of angles of 360° are made by silver-plated film (high reflection) process on aluminum sheet raw materials, and by cutting and other mechanical and chemical related methods. Then use methods such as printing, dispensing, and spraying to coat fluorescent pink segments 201, 202, and 203 on each substrate segment respectively. Through a specific jig, three aluminum substrate segments 103, 106, and 107 coated with fluorescent pink segments are assembled. Forming an outer diameter of 55mm and an inner diameter of 12mm circular fluorescent pink disc layer.

[0041]

Embodiment 2

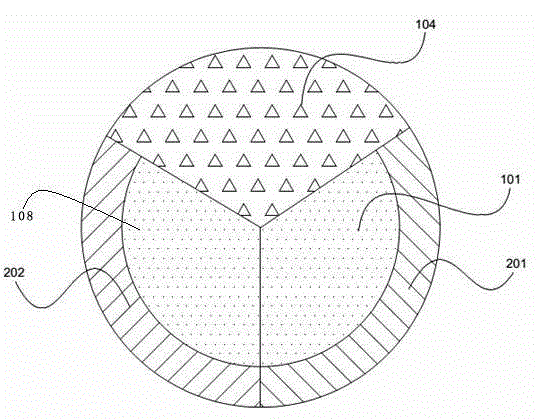

[0043] figure 2Shown is Example 2 of the present invention, which consists of a diffuser substrate fan 104 with a haze of 100% and a thickness of 1 mm, and two aluminum sheets with a thickness of 0.8 mm and a reflectivity of 95% with an aluminum-coated metal film on the surface The substrate segments 101, 108 are assembled. A fluorescent pink wheel layer formed by coating different fluorescent pink segments 201, 202 on two aluminum substrate segments coated with metal film, and then assembling with the diffuser substrate segment 104. The diffuser 104 and the aluminized film-coated aluminum plate substrate fan pieces 101 and 108 are made by the aluminized film process on the raw material of the aluminum sheet, and through mechanical and chemical related methods such as cutting. Then use printing, dispensing, spraying, etc. to coat the fluorescent pink segments 201 and 202 on the aluminum substrate segments 101 and 108 respectively. Through a specific jig, the diffuser segment...

Embodiment 3

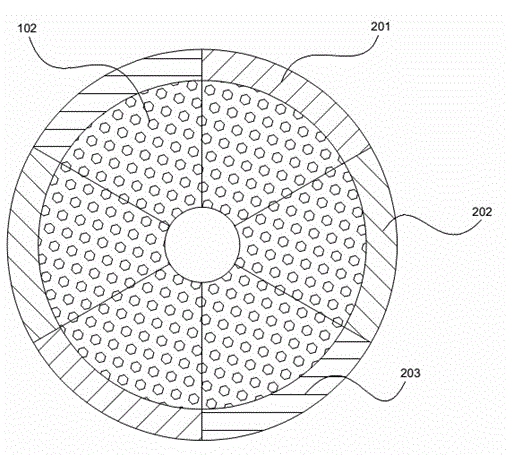

[0046] image 3 Shown is Embodiment 3 of the present invention, which is assembled from 6 pieces of glass fans with a thickness of 0.7mm, an angle of 60°, an outer circle diameter of 50mm, and an inner circle of less than 12mm. A fluorescent pink wheel layer assembled after coating different fluorescent pink segments 201, 202, and 203 on six glass fan pieces. By coating the glass surface with a high-transparency blue film, and through mechanical processing such as machine cutting, 6 glass fan pieces 102 with an angle of 60° are formed, and then printing, dispensing, spraying, etc. are applied to each glass fan. Fluorescent pink segments 201, 202, and 203 are respectively coated on the sheet. By means of a specific jig, 6 pieces of glass segments 102 coated with fluorescent pink segments are assembled to form a fully transparent circular fluorescent pink wheel layer with an outer diameter of 50 mm and an inner diameter of 12 mm.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com