Strip-shaped spraying head for electrostatic spinning

An electrospinning and strip-shaped technology, which is applied in the field of strip-shaped nozzles for electrospinning, can solve the problems of porous tube blockage, difficult to solve, and high injection voltage threshold, and achieve high thickness consistency, no nozzle blockage, and high production efficiency. rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

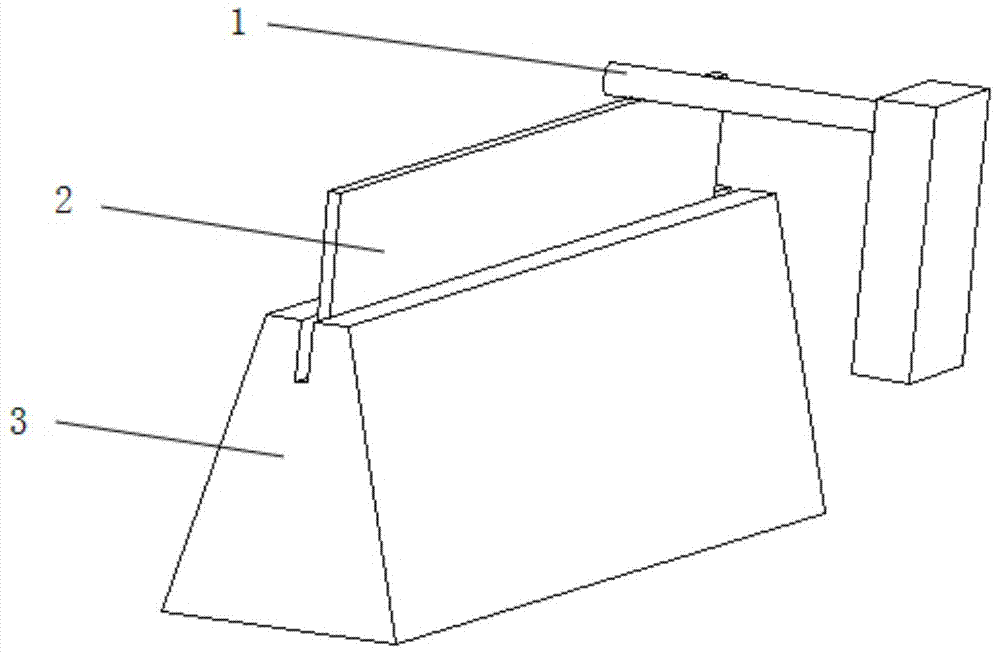

[0012] see figure 1 , the embodiment of the present invention is provided with solution feeding mechanism 1, strip-shaped conductive sheet 2 and conductive sheet support 3; Strip-shaped conductive sheet 2 is fixedly connected with conductive sheet support 3, and solution feeding mechanism 1 is used for spinning solution Evenly coated on the edge surface of one side of the long side of the strip-shaped conductive sheet 2.

[0013] The top view projection of the strip-shaped conductive sheet can be a straight line, an arc, a spiral, a circle or an ellipse, and the like.

[0014] The intuitive structure of the strip-shaped conductive sheet is a continuous, smooth transition, and no obvious corner curve; after the strip-shaped conductive sheet curve is equivalent to a mathematical language description, any section of the curve intercepted on the conductive sheet overlooking the projection curve is Continuously differentiable curves.

[0015] The thickness of the strip-shaped con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com