A method for improving the magnetic properties of sintered NdFeB by grain boundary diffusion

A technology of grain boundary diffusion and NdFeB, which is applied in the direction of magnetic materials, magnetic objects, and inorganic materials, can solve the problems of magnet sample thickness limitation and immature grain boundary diffusion process, and improve the coercive force and distribution of magnets. High uniformity and thickness consistency, the effect of improving depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

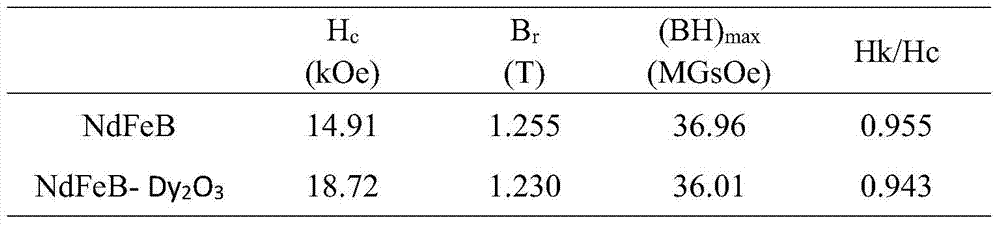

Embodiment 1

[0025] 1.0cm thick NdFeB magnet with a density of 92% is coated with Dy 2 o 3 Suspension, the coating thickness is 0.5mm;

[0026] Step 1: Orient the sintered NdFeB magnetic powder under a magnetic field of 1.5T, and make a green body under 200MPa cold isostatic pressing;

[0027] Step 2: Carry out semi-densification sintering of the blank in a vacuum sintering furnace, the sintering temperature is 940°C, heat preservation for 2 hours, and the density is 92%;

[0028] Step 3: Put Dy 2 o 3 The powder is dispersed in anhydrous ethanol, and after mixing evenly, a suspension is obtained with a viscosity of 100mpa.s;

[0029] Step 4: Evenly coat the suspension on the surface of a sintered NdFeB magnet with a density of 92%, with a coating thickness of 0.5mm, and dry it in a vacuum drying oven at a drying temperature of 80°C for 1 hour;

[0030] Step 5: Incorporate Dy 2 o 3 The coated semi-dense sintered NdFeB is vacuum sintered and tempered in a vacuum sintering furnace. Th...

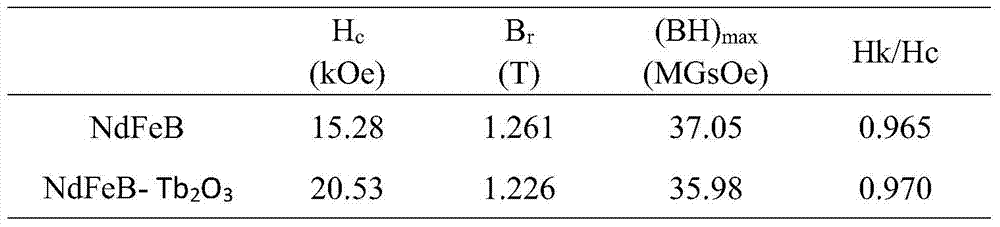

Embodiment 2

[0037] 1.0cm thick NdFeB magnet with 95% density coated with Tb 2 o 3 Suspension, the coating thickness is 1mm;

[0038] Step 1: Orientate the sintered NdFeB magnetic powder under a magnetic field of 2.0T, and make a green body under cold isostatic pressing of 200MPa;

[0039] Step 2: Carry out semi-densification sintering of the blank in a vacuum sintering furnace, the sintering temperature is 950°C, the temperature is kept for 3 hours, and the density is 95%;

[0040] Step 3: Put Tb 2 o 3 The powder is dispersed in a mixed solvent of propylene glycol and polyvinyl alcohol, and after mixing evenly, a suspension is obtained with a viscosity of 200mpa.s;

[0041] Step 4: Evenly coat the suspension on the surface of a sintered NdFeB magnet with a density of 95%, with a coating thickness of 1mm, and dry it in a vacuum drying oven at a drying temperature of 50°C for 2 hours;

[0042] Step 5: Incorporate Tb-containing 2 o 3 The coated semi-dense sintered NdFeB is vacuum sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com