Cross lapping machine

A net laying and body technology, applied in textiles and papermaking, winding strips, non-woven fabrics, etc., can solve problems affecting product quality, waste, etc., achieve uniform thickness, improve quality, and change the effect of drafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

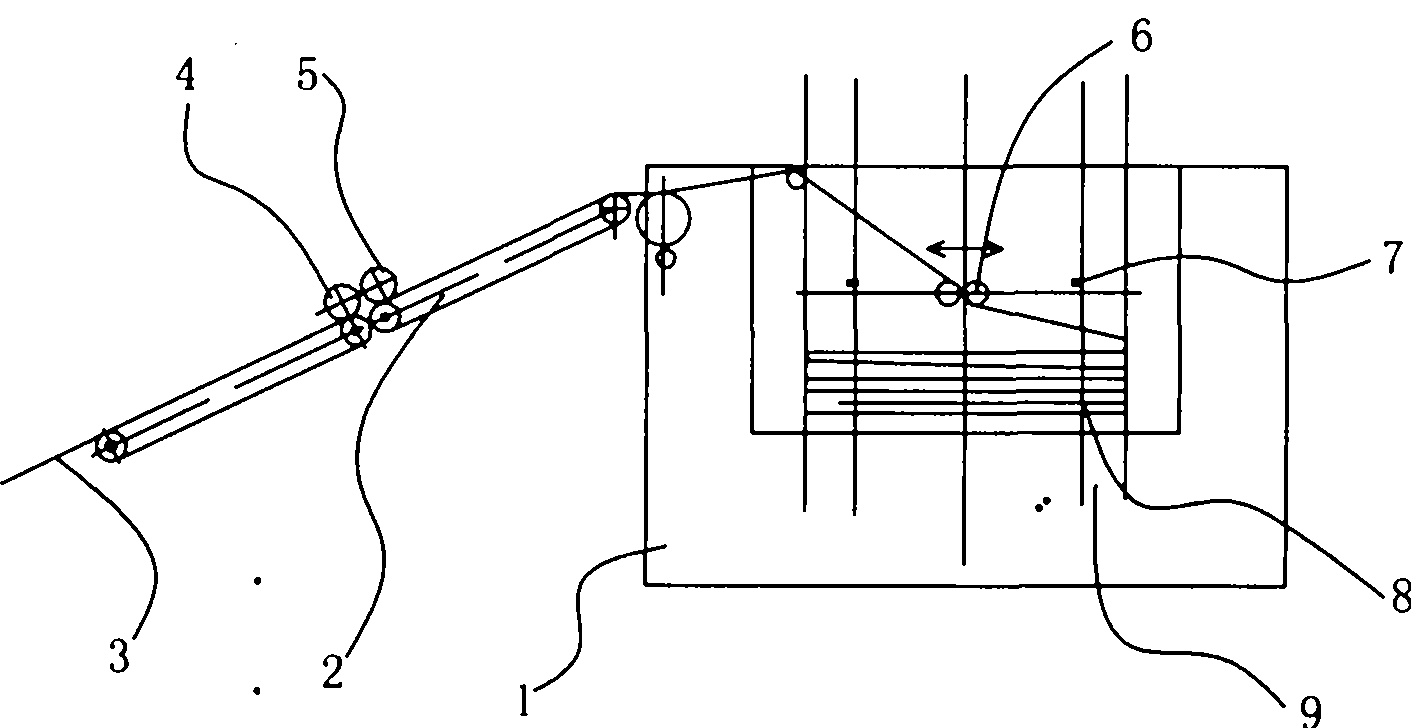

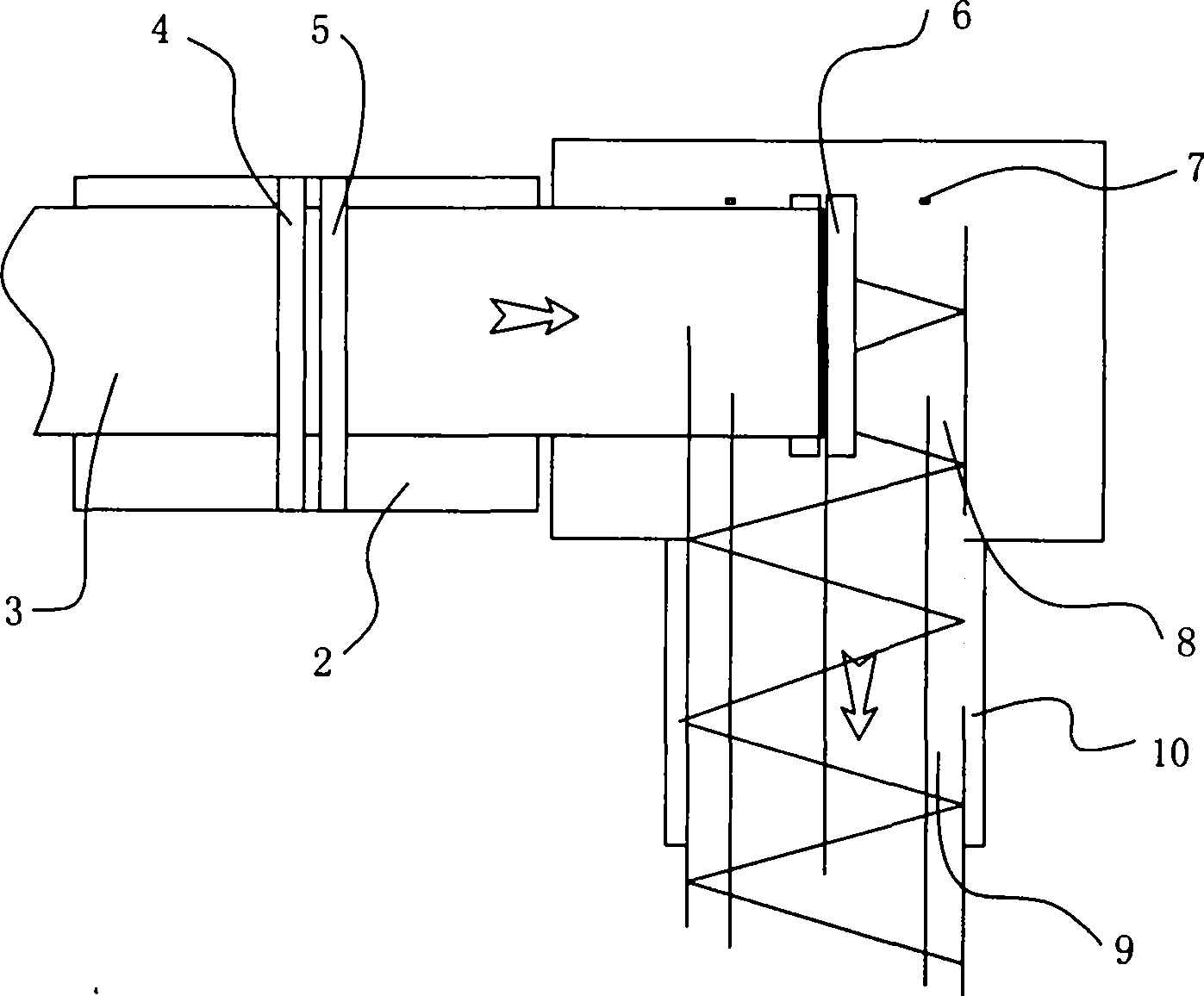

[0011] The present invention as figure 1 , 2 As shown, it includes a controller, a machine body 1, a discharge table 10, a web laying trolley 6, and a feeding and conveying curtain 2 of the fiber web 3. The feeding and conveying curtain 2 is at 90 degrees to the discharging platform 10. It swings back and forth in the feeding direction, and it also includes the position sensing device of the net laying trolley 6 and the drafting mechanism. Two inductors 7, two inductors 7 are respectively connected to the controller; the drafting mechanism includes a pair of traction roller one 4 and traction roller two 5 which are arranged in parallel on the top of the net conveying curtain 2, and the traction roller one 4 is driven by a constant speed motor Driven, traction roller two 5 is driven by variable speed motor, constant speed motor, variable speed motor are connected controller respectively.

[0012] The controller is provided with the position data of the web-laying trolley 6 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com