Automatic spraying machine for enamelled pressed steel

An automatic spraying and steel plate technology, which is applied in the field of decorative building materials, can solve the problems of low efficiency and unstable spraying quality, and achieve the effect of good quality, stable spraying quality and improved thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

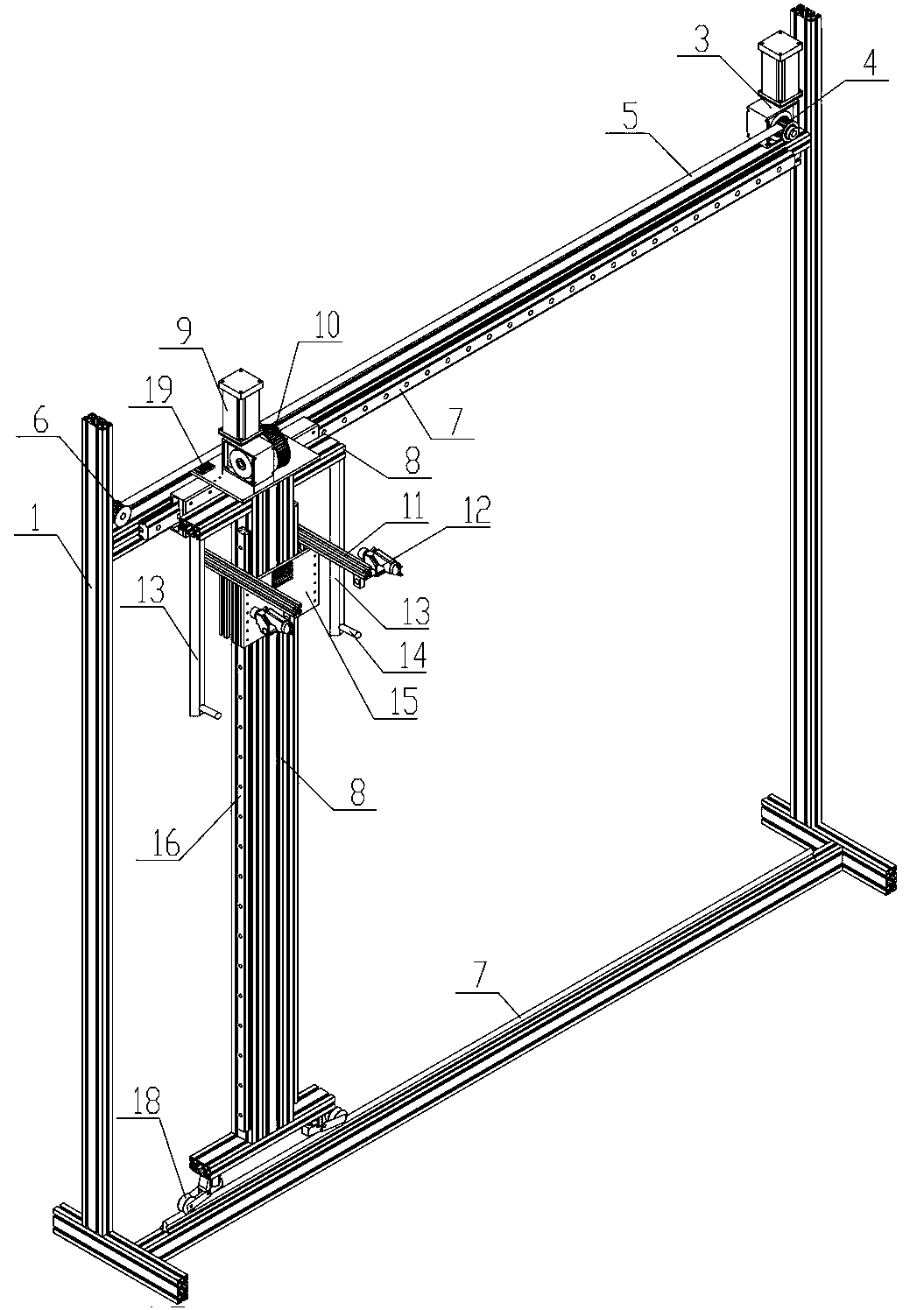

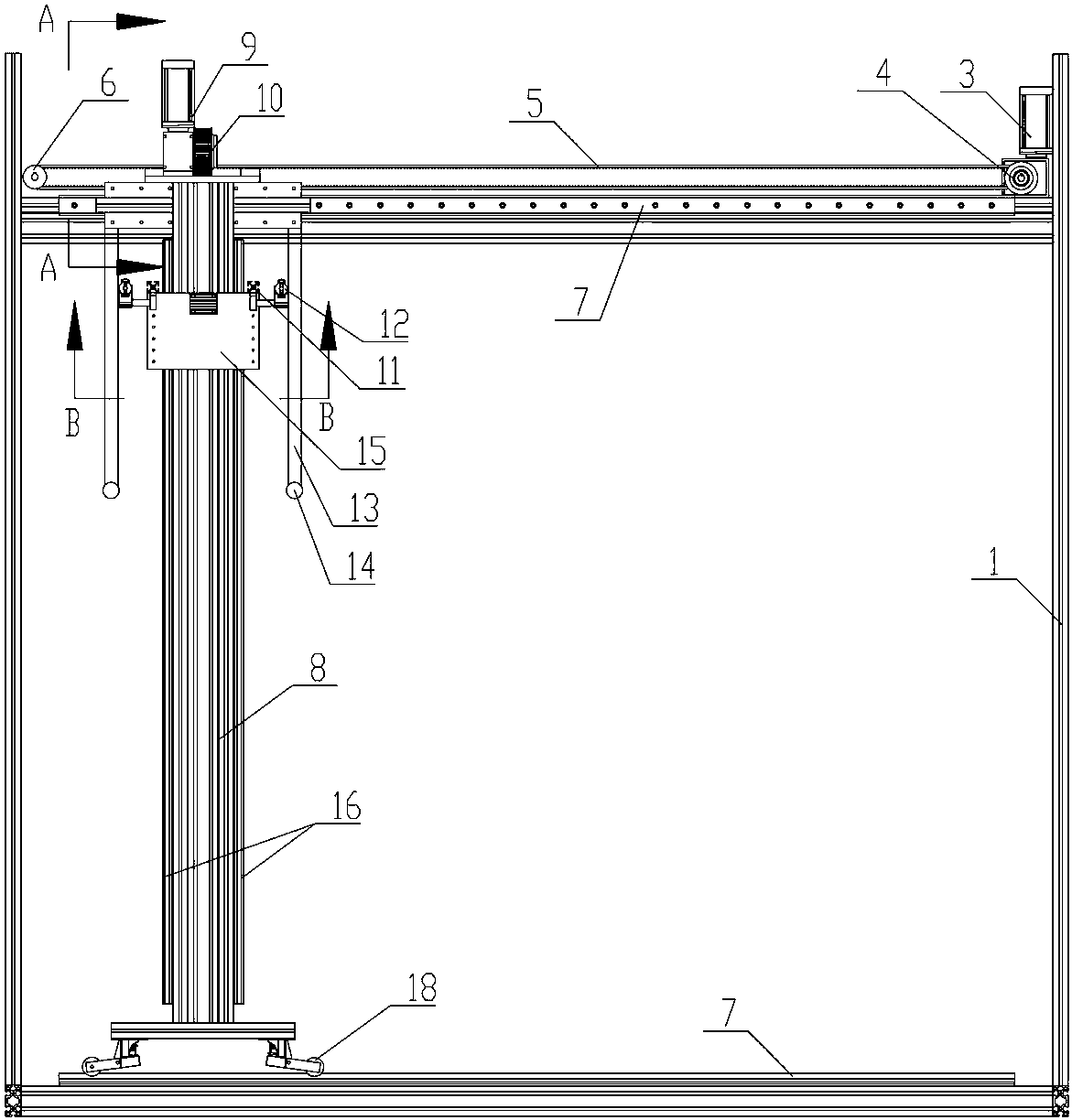

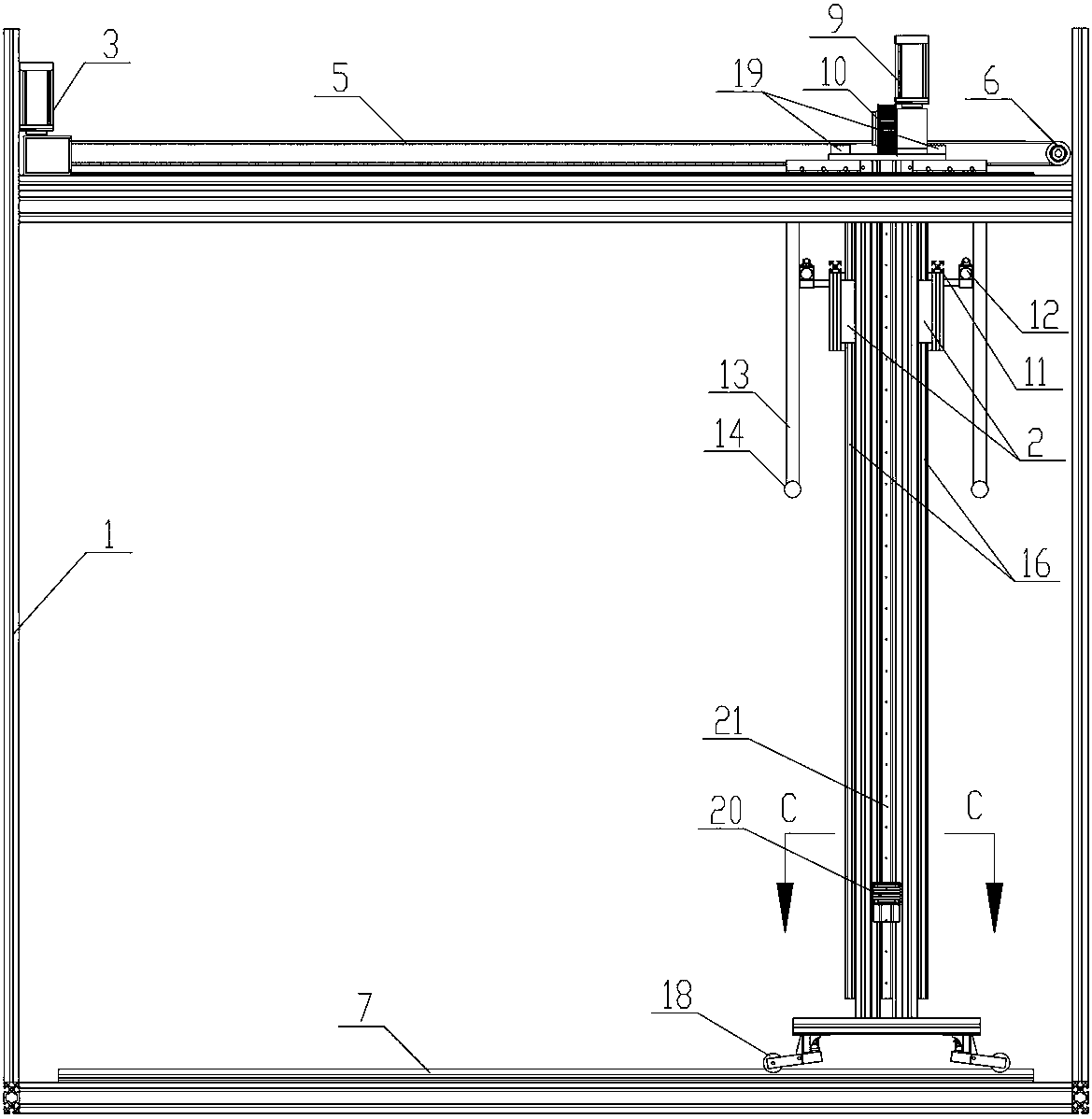

[0018] see Figure 1-6 , the present embodiment includes a frame 1, a horizontal guide rail 7 is installed on the bottom of the frame 1 and the top of the frame 1, a horizontally movable bracket 8 is installed on the two horizontal guide rails 7, and a driving device A3 is installed on the top of the frame 1 It is used to drive the bracket 8 to move horizontally. The top of the bracket 8 is equipped with a driving device B9. A vertical guide rail 16 is installed on each side of the bracket 8. Each of the two vertical guide rails 16 is equipped with a sliding seat 2 and two sliding seats 2. A slide plate 15 is installed on the front end of the support 8, a vertical track 21 is installed on the rear end of the support 8, and a counterweight device 20 that can move along the track 21 is installed on the track 21, and a gear is connected to the output end of the drive device B9. 10. The gear 10 is equipped with a chain (not shown) engaged with it, one end of the chain (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com