Enhanced phosphorus removal membrane bioreactor

A biological reaction device and phosphorus membrane technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that the phosphorus removal mechanism is not very clear, and achieve the promotion of mixing, Extend the cleaning cycle and improve the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

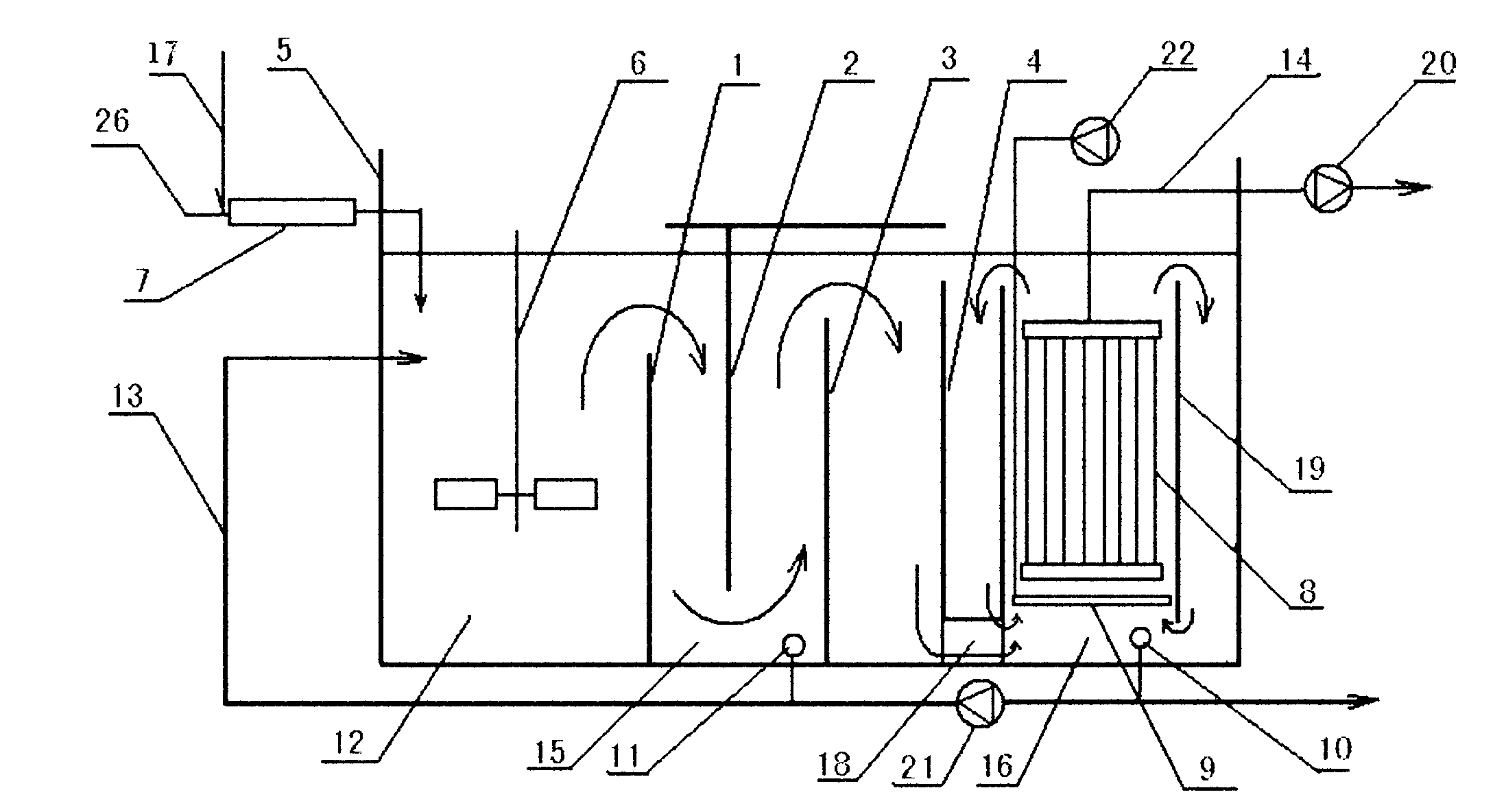

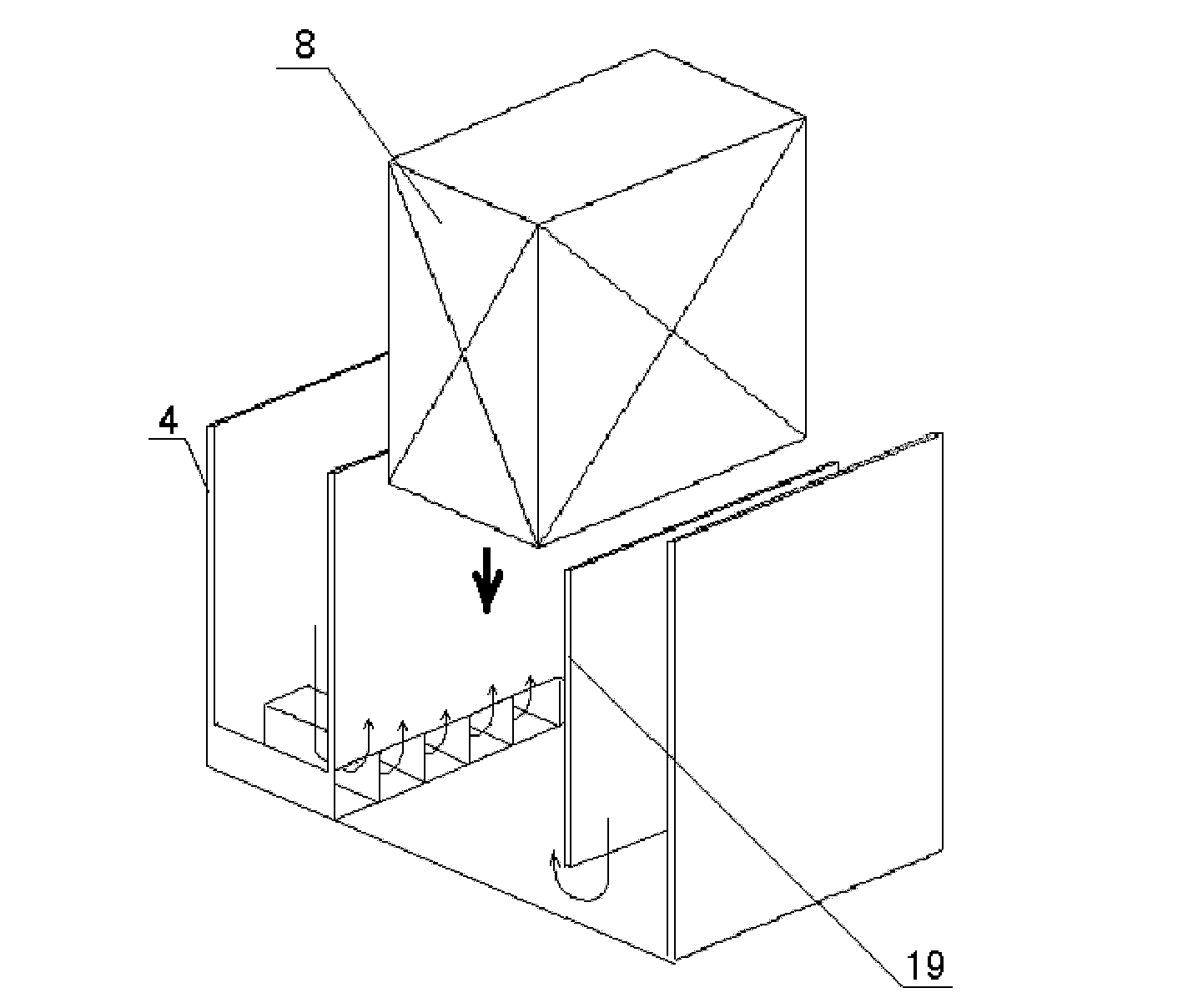

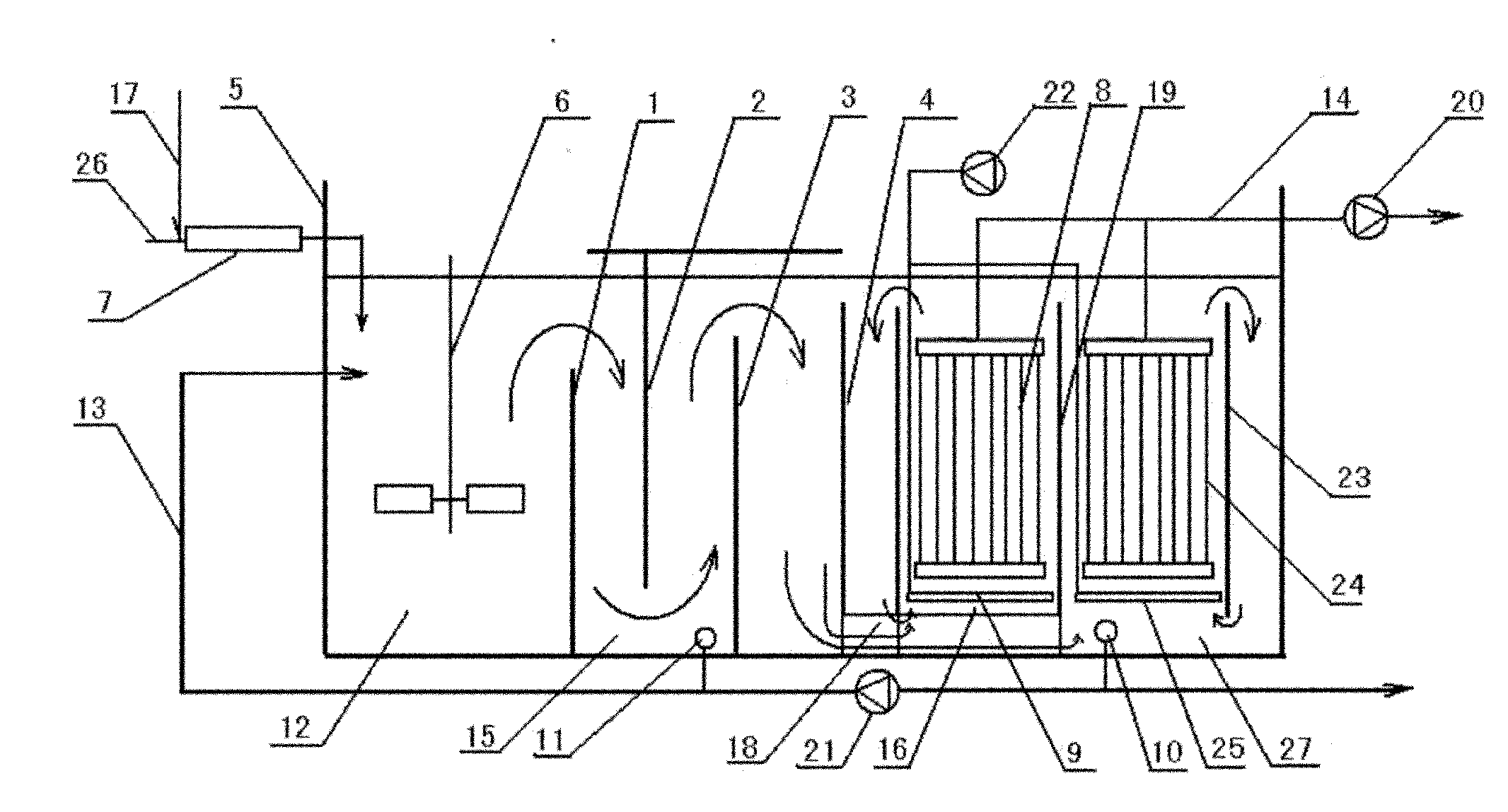

[0025] A kind of enhanced dephosphorization membrane bioreactor (see figure 1 and figure 2), including the reaction pool 5, the first diversion wall 1, the second diversion wall 2, the third diversion wall 3, the interlayer type diversion wall 4 and the fifth diversion wall 19 are arranged in the reaction pool 5 successively. The bottom of a diversion wall 1, the bottom of the third diversion wall 3 and the bottom of the sandwich type diversion wall 4 are respectively connected to the bottom wall of the reaction tank 5, and the first diversion wall 1 and the left side wall of the reaction tank 5 There is an aerobic zone 12 between them, an anaerobic zone 15 between the first diversion wall 1 and the interlayer diversion wall 4, and a first membrane filtration region 16 between the sandwich diversion wall 4 and the fifth diversion wall 19. , the top of the first dive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com