Efficient composite phosphorus removal agent and preparation method thereof

A compound dephosphorization agent and dephosphorization agent technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Good, complex manufacturing methods and processes, etc., to achieve the effect of enhancing phosphorus removal effect and efficiency, improving functional diversity, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

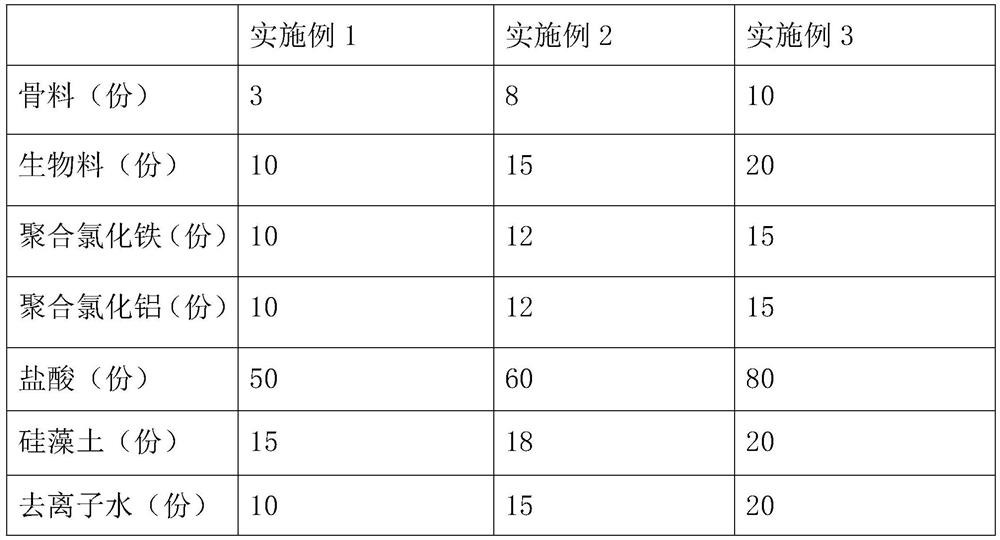

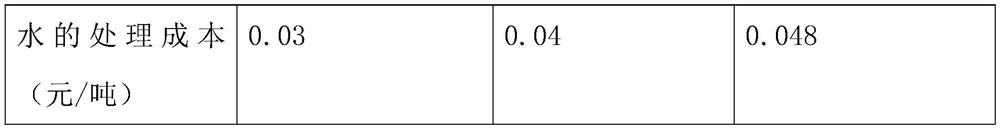

[0031] A high-efficiency composite phosphorus removal agent, the formula includes: aggregate, biological material, polyferric chloride, polyaluminum chloride, hydrochloric acid, diatomaceous earth and deionized water, the parts by weight of each component are: 3 parts Aggregate, 10 parts of biomass, 10 parts of polyferric chloride, 10 parts of polyaluminum chloride, 50 parts of hydrochloric acid, 15 parts of diatomaceous earth and 10 parts of deionized water, and the aggregate is made of shells, The pig bone and the beef bone are mixed according to the ratio of 3:1:1, the biological material is the mixture of coconut shell, straw and dead wood according to the ratio of 1:1:1, and the concentration of hydrochloric acid is 37%.

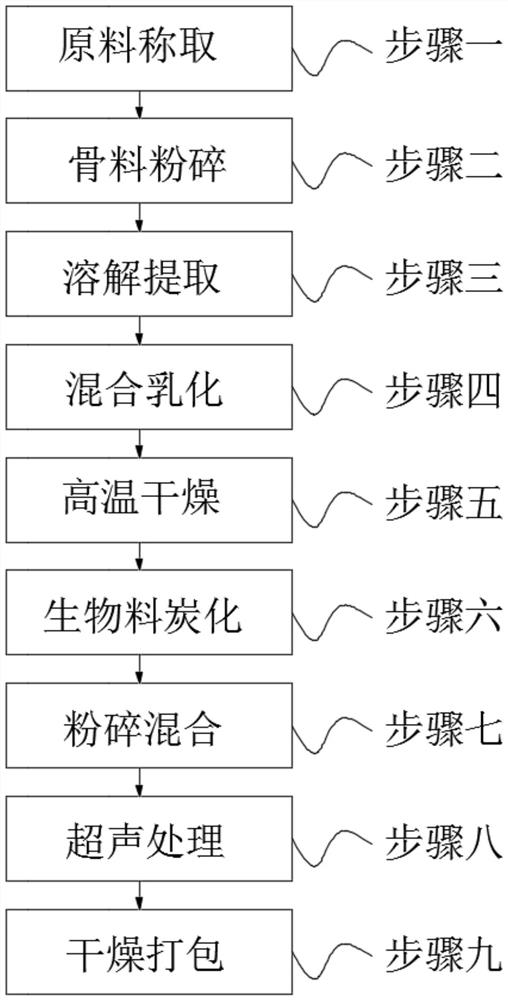

[0032] A preparation method of a high-efficiency composite phosphorus removal agent, comprising the following steps, step 1, weighing raw materials; step 2, crushing aggregates; step 3, dissolving and extracting; step 4, mixing and emulsifying; Biomass ...

Embodiment 2

[0043] A high-efficiency composite phosphorus removal agent, the formula includes: aggregate, biological material, polyferric chloride, polyaluminum chloride, hydrochloric acid, diatomaceous earth and deionized water, the parts by weight of each component are: 8 parts Aggregate, 15 parts of biomass, 12 parts of polyferric chloride, 12 parts of polyaluminum chloride, 60 parts of hydrochloric acid, 18 parts of diatomaceous earth and 15 parts of deionized water, and the aggregate is made of shells, The pig bone and the beef bone are mixed according to the ratio of 3:1:1, the biological material is the mixture of coconut shell, straw and dead wood according to the ratio of 1:1:1, and the concentration of hydrochloric acid is 37%.

[0044]A preparation method of a high-efficiency composite phosphorus removal agent, comprising the following steps, step 1, weighing raw materials; step 2, crushing aggregates; step 3, dissolving and extracting; step 4, mixing and emulsifying; Biomass c...

Embodiment 3

[0055] A high-efficiency composite phosphorus removal agent, the formula includes: aggregate, biological material, polyferric chloride, polyaluminum chloride, hydrochloric acid, diatomaceous earth and deionized water, the parts by weight of each component are: 10 parts Aggregate, 20 parts of biological material, 15 parts of polyferric chloride, 15 parts of polyaluminum chloride, 80 parts of hydrochloric acid, 20 parts of diatomaceous earth and 20 parts of deionized water, and the aggregate is made of shells, The pig bone and the beef bone are mixed according to the ratio of 3:1:1, the biological material is the mixture of coconut shell, straw and dead wood according to the ratio of 1:1:1, and the concentration of hydrochloric acid is 37%.

[0056] A preparation method of a high-efficiency composite phosphorus removal agent, comprising the following steps, step 1, weighing raw materials; step 2, crushing aggregates; step 3, dissolving and extracting; step 4, mixing and emulsifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com