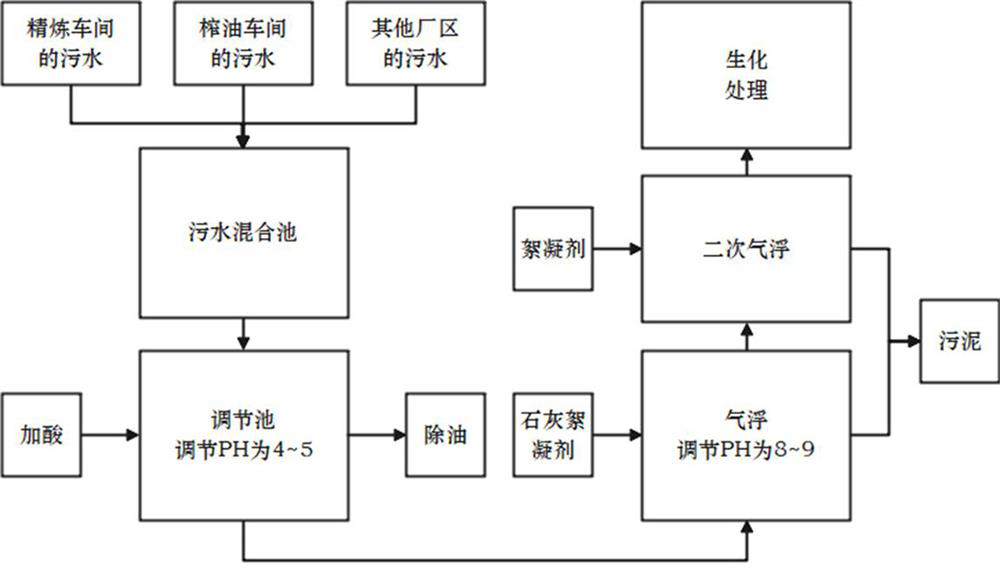

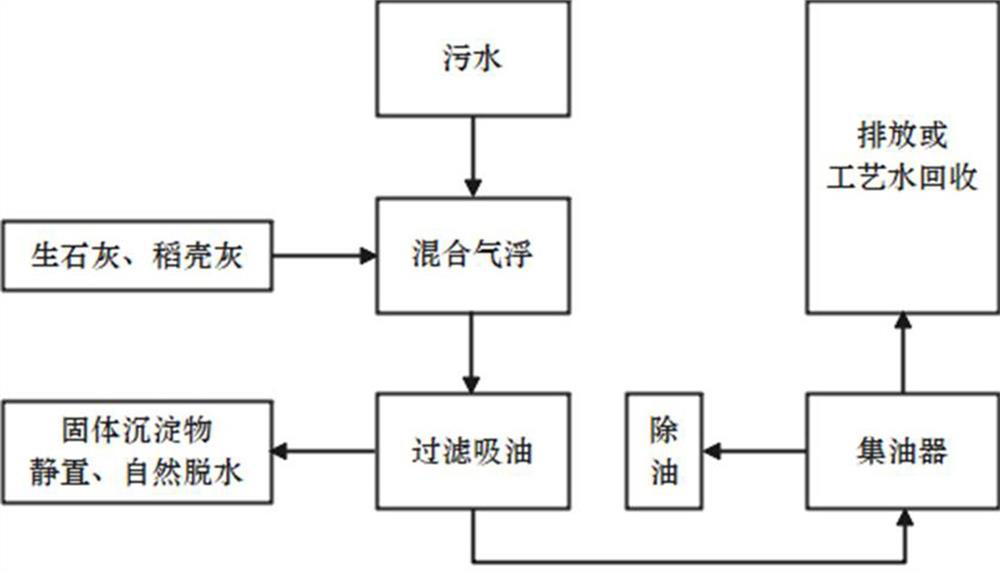

Edible oil production sewage treatment system and process

A technology for the production of sewage and treatment systems, which is used in water/sewage treatment, food industry wastewater treatment, flotation water/sewage treatment, etc. The effect of short and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

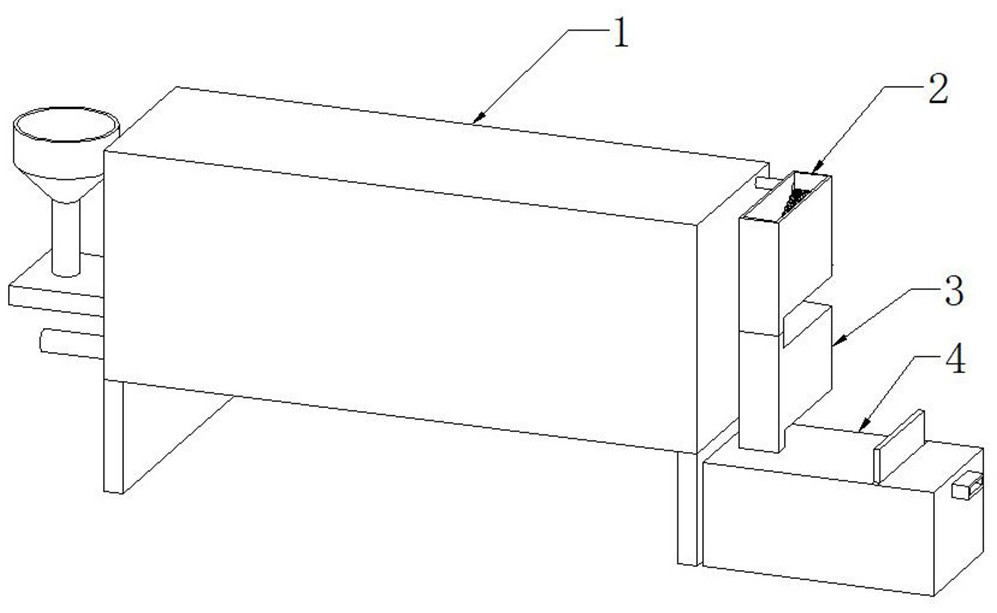

Image

Examples

Embodiment 1

[0067] 1 ton of edible oil production sewage containing 2500ppm of oil, 140ppm of phosphorus, and 25000ppm of COD is processed by the device of the present invention and matched with the above method steps, wherein 3kg of rice husk ash, 1kg of quicklime, and the sewage discharged after treatment is tested, and the oil content is 9ppm , containing 4.5ppm of phosphorus, and 260ppm of COD, the total process cost of the whole process is 3.6 yuan, and the processing time is 1.5h.

Embodiment 2

[0069] 1 ton of edible oil production sewage containing 1600ppm of oil, 60ppm of phosphorus, and 15000ppm of COD is processed by the device of the present invention and matched with the above method steps, wherein 2kg of rice husk ash, 0.8kg of quicklime, and the sewage discharged after treatment is detected. 8.2ppm, phosphorus 3.9ppm, COD 259ppm, the total process cost of the whole process is 3.3 yuan, and the treatment time is 1.5h.

Embodiment 3

[0071] 1 ton of edible oil production sewage containing 1600ppm of oil, 60ppm of phosphorus, and 15000ppm of COD is processed by the device of the present invention and matched with the above method steps, wherein rice husk ash is 3kg, quicklime is 0.6kg, and the sewage discharged after treatment is detected. 8.3ppm, phosphorus 4.2ppm, COD 261ppm, the total process cost of the whole process is 3.2 yuan, and the processing time is 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com