Gluing device and gluing method

A gluing device and gluing technology, applied in the direction of the surface coating liquid device, coating, adhesive, etc., can solve the problems of broken glue line, thinning, etc., achieve uniform flow speed, solve glue breaking and glue line thinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

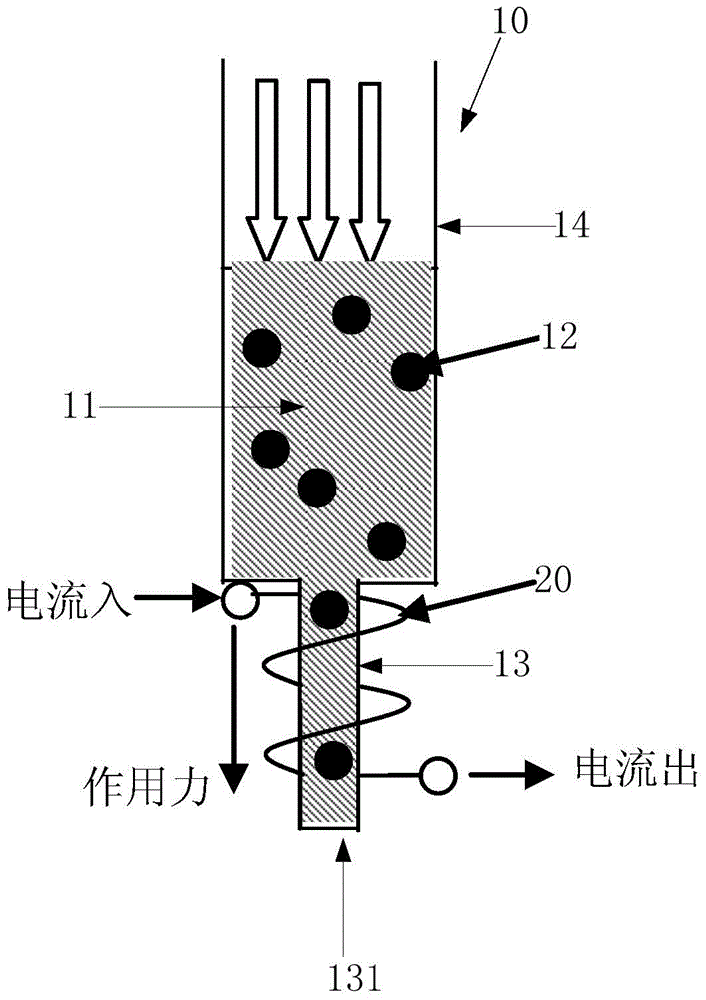

[0040] The gluing device described in the specific embodiment of the present invention includes:

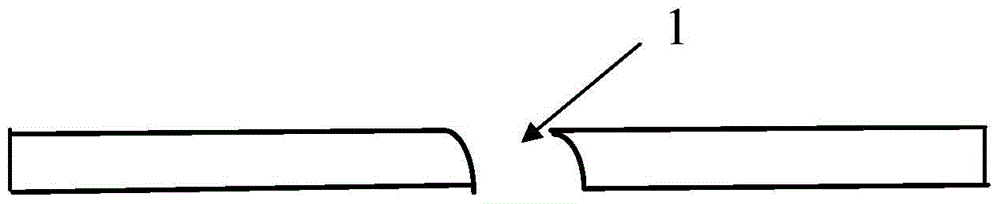

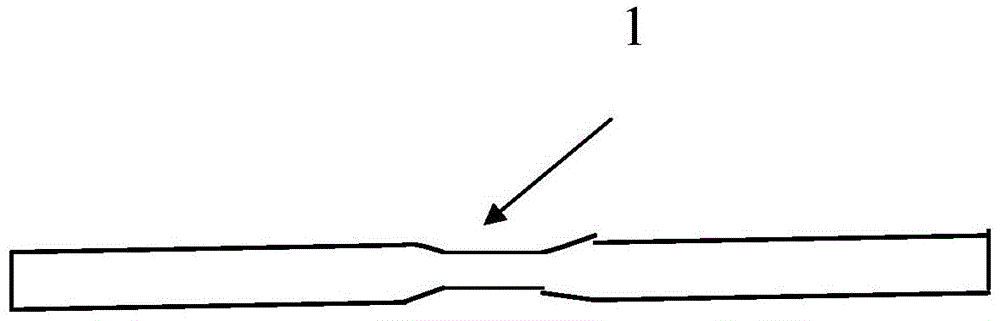

[0041] a dispensing head for guiding the adhesive, to which magnetic material is added, in the direction of dispensing;

[0042] The magnetic field generating structure is used to apply an induced magnetic field to the dripping head, and the magnetic material exerts a force that is the same as or opposite to the dripping direction through the induced magnetic field.

[0043] The gluing device described in the specific embodiment of the present invention, by adding a magnetic material to the adhesive to be instilled, utilizes the induced magnetic field applied to the infusion head to apply a force to the magnetic material that is the same as or opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com