Device for electroplating steel band coating

An electroplating device and metal coating technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of high cost and achieve the effect of uniform separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

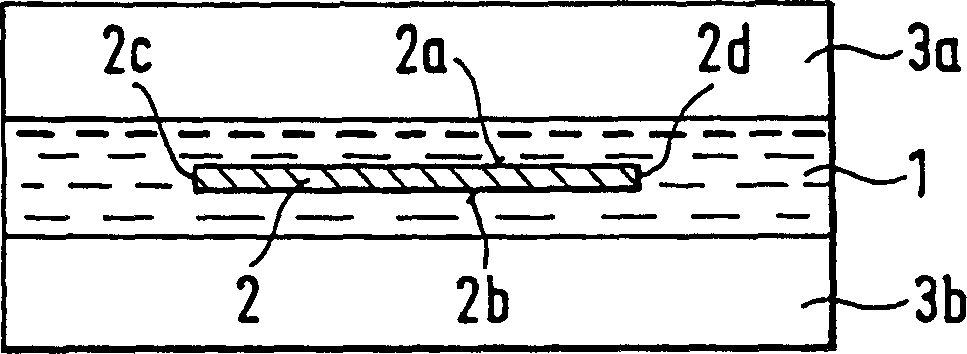

[0035] figure 1 Shown is a steel strip electroplating plant in which a steel strip 2 is immersed in an electrolyte 1 for operation. Parallel to the surfaces 2a, 2b of the steel strip 2, upper and lower anodes 3a, 3b are arranged at a small distance from the surface. The width of the upper and lower anodes 3a, 3b depends on the maximum width of the steel strip to be coated. For example, when the width of the steel strip is 1850mm, the width of the anode can be 2050mm.

[0036] During the metallization process, current flows from the anodes 3a, 3b to the steel strip 2 which works as cathode. Metallic zinc is thus deposited from the electrolyte 1 on the strip surfaces 2a, 2b.

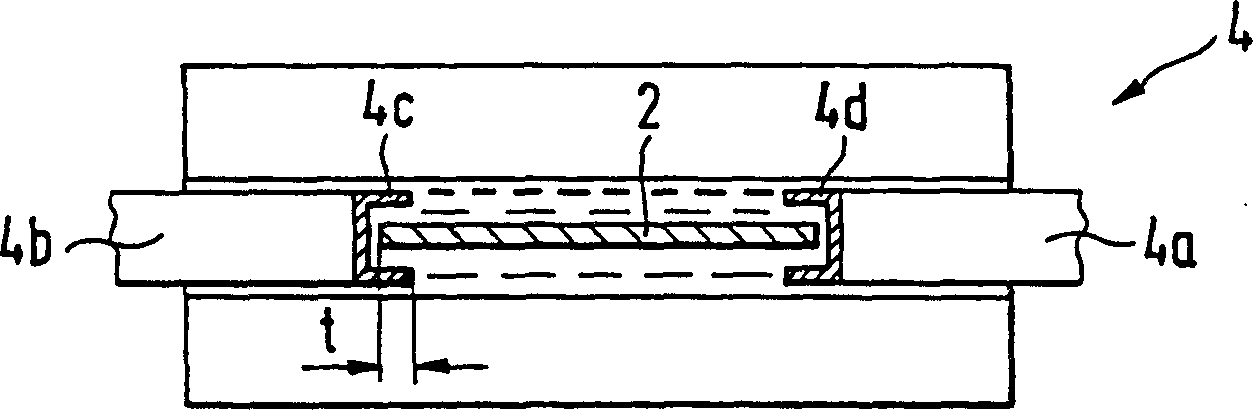

[0037] In order to prevent excessive deposition of metal zinc on the edges 2c, 2d of the steel strip 2, a so-called edge mask 4 is provided in the prior art, such as figure 2 shown. The mask consists of insulating plates 4a, 4b and U-shaped pieces 4c, 4d surrounding the strip edges 2c, 2d.

[0038] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com