Patents

Literature

39results about How to "From impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

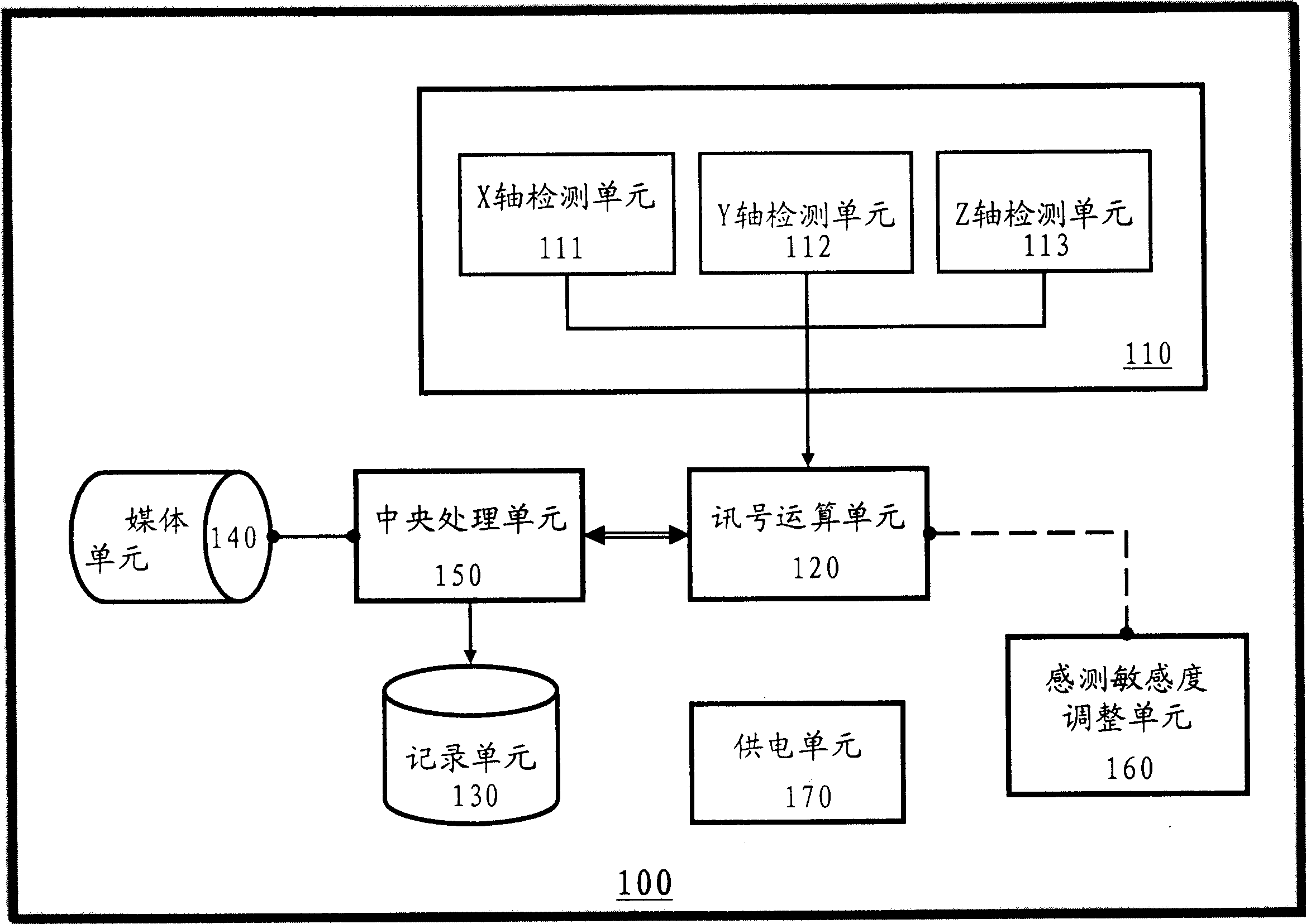

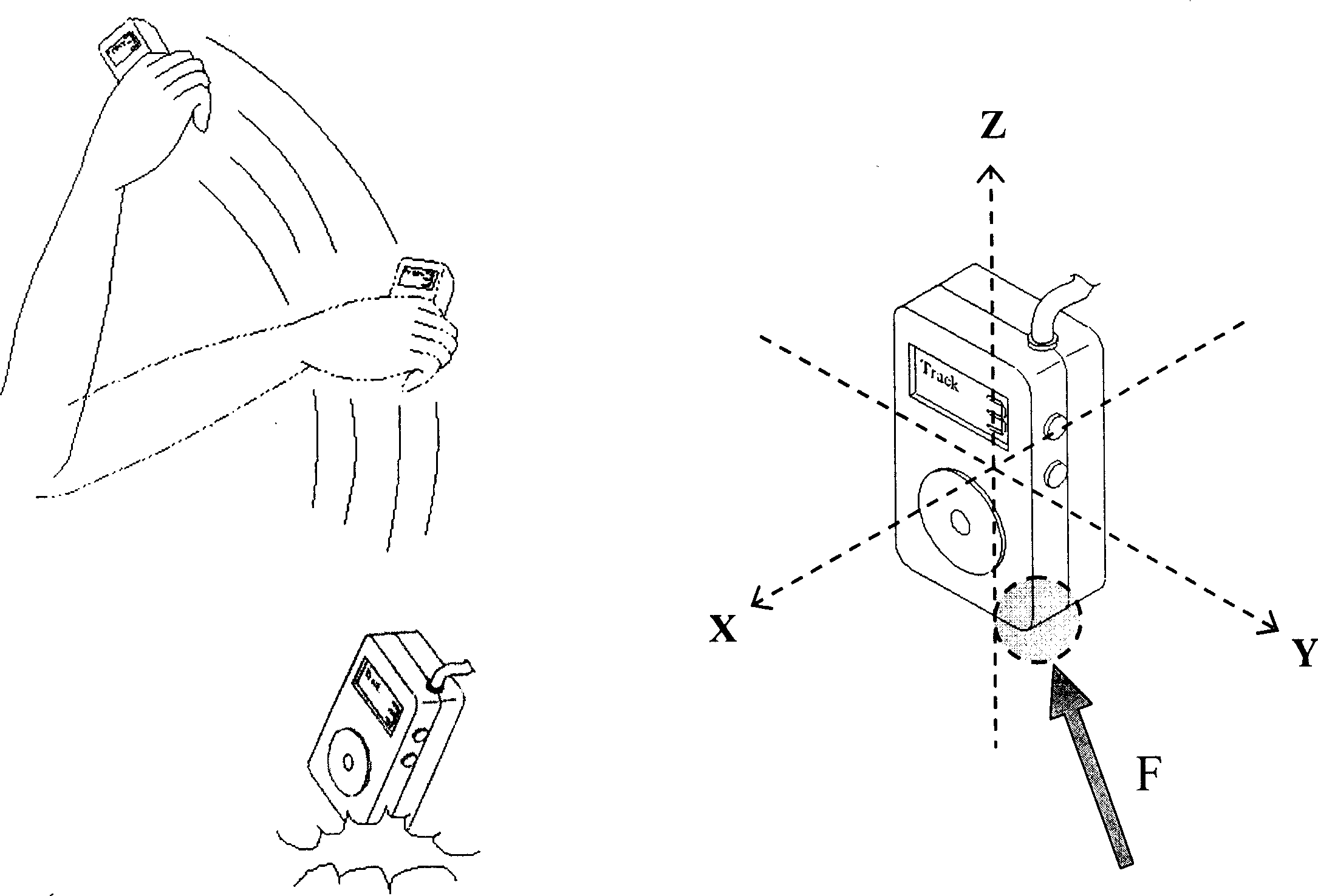

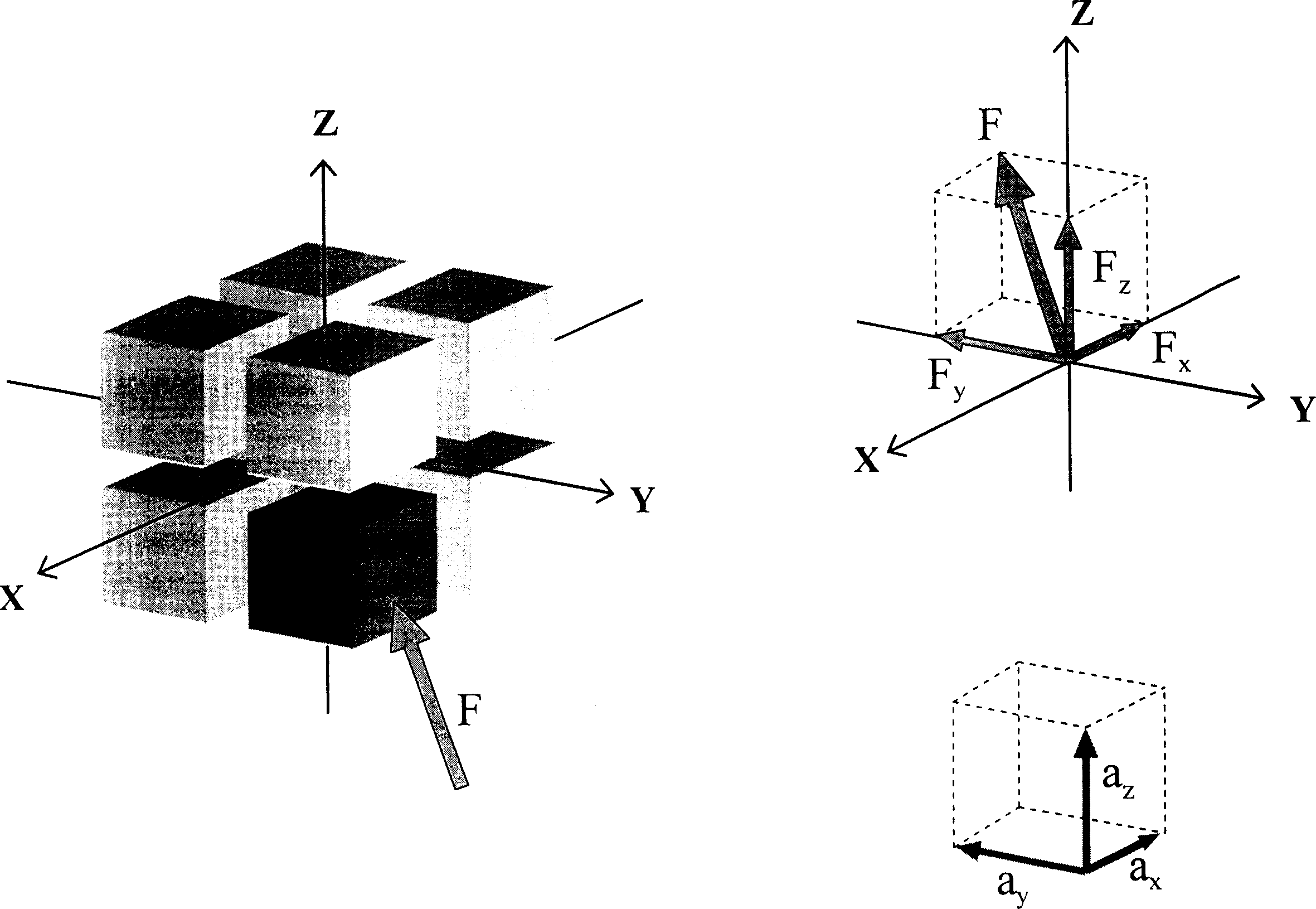

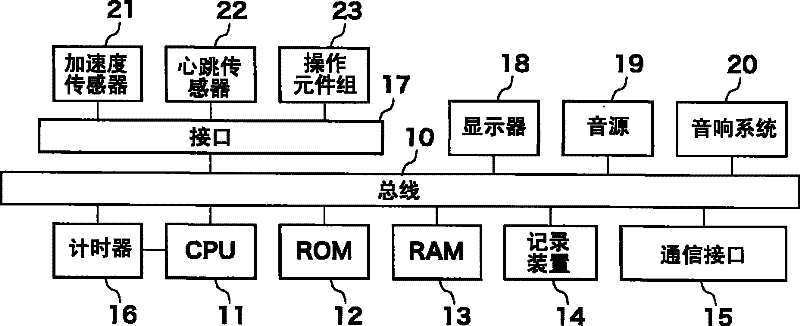

Medium apparatus protection mechanism capable of sensing and recording external force impact and method thereof

InactiveCN1862439AImprove satisfactionLow costDigital data processing detailsProtection mechanismEngineering

The present invention relates to a medium equipment protection mechanism capable of sensing and recording external impact and its method. It is characterized by that when the medium equipment is subjected to external impact, said protection mechanism can calculate and record related impact information and can adopt power-off measure to protect said medium equipment.

Owner:ALTOB

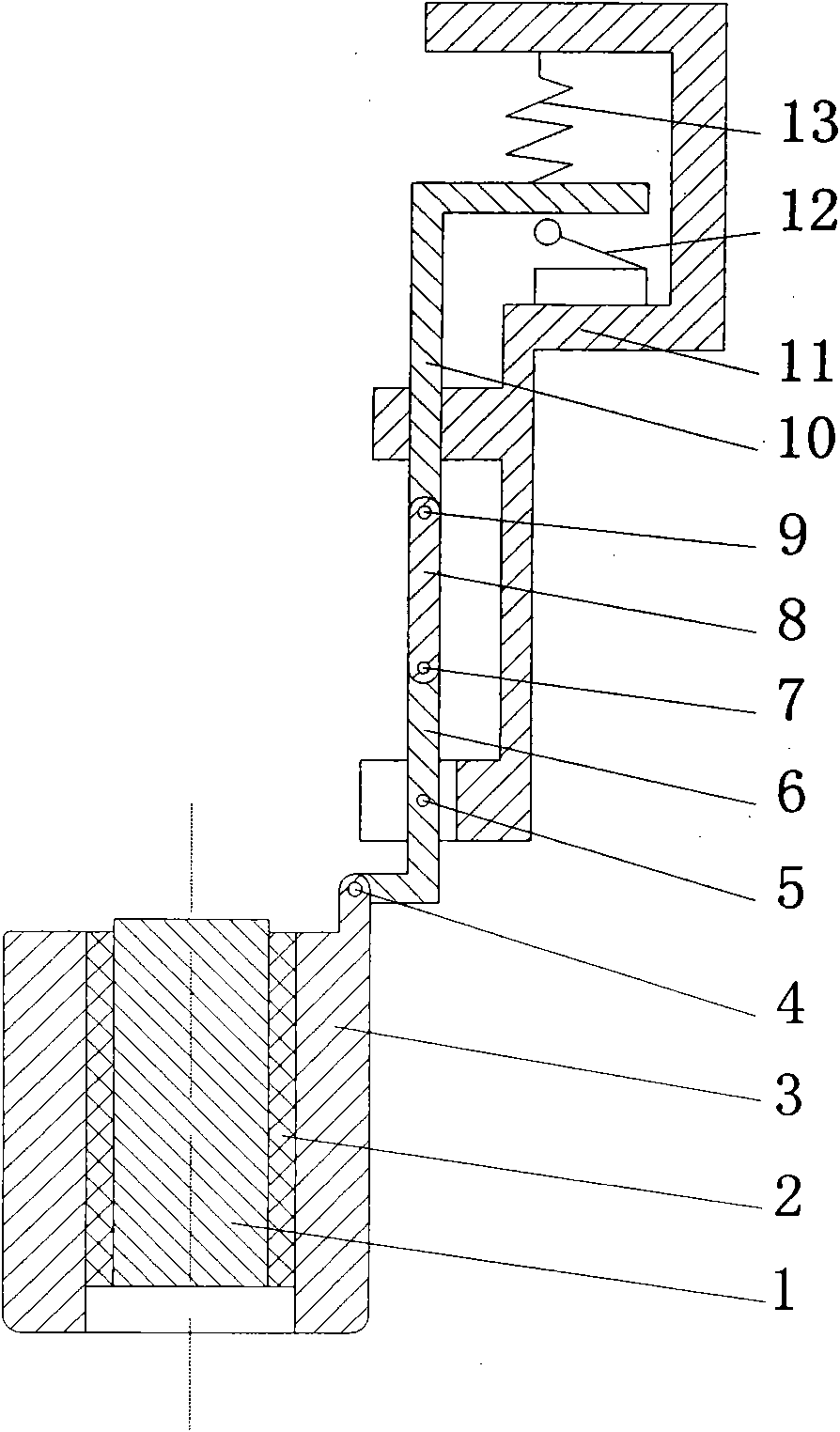

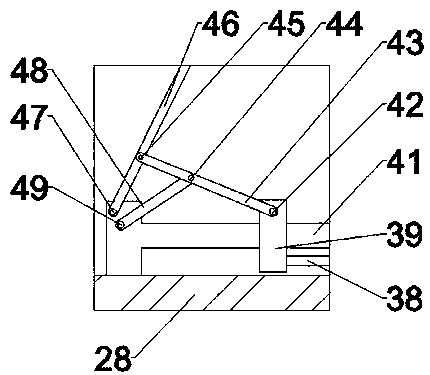

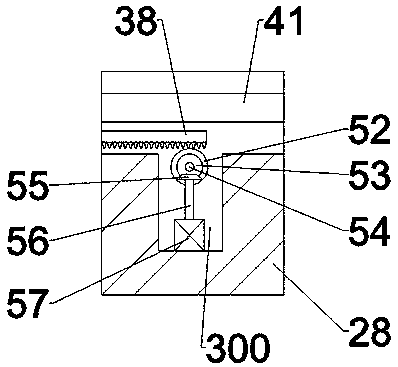

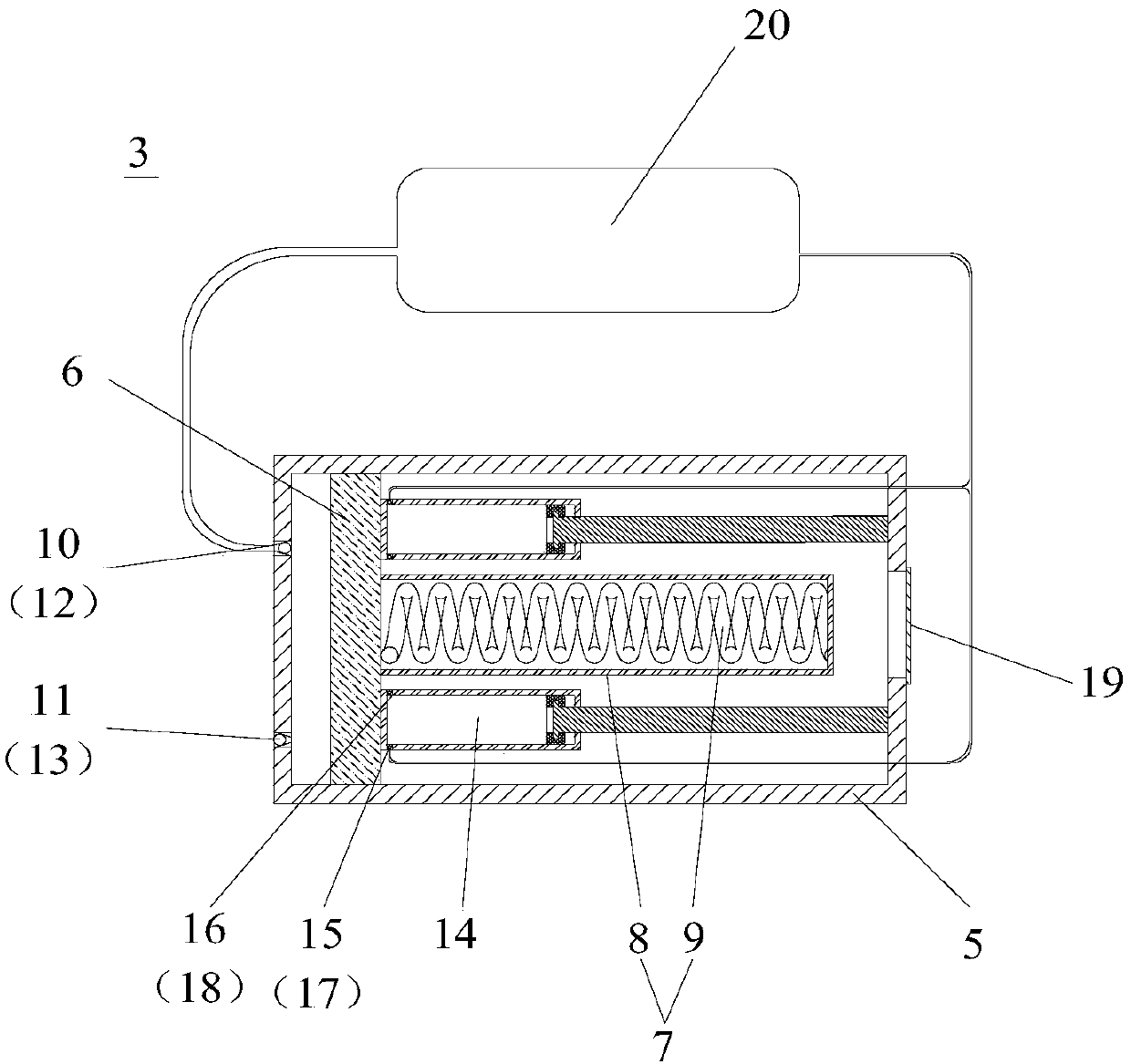

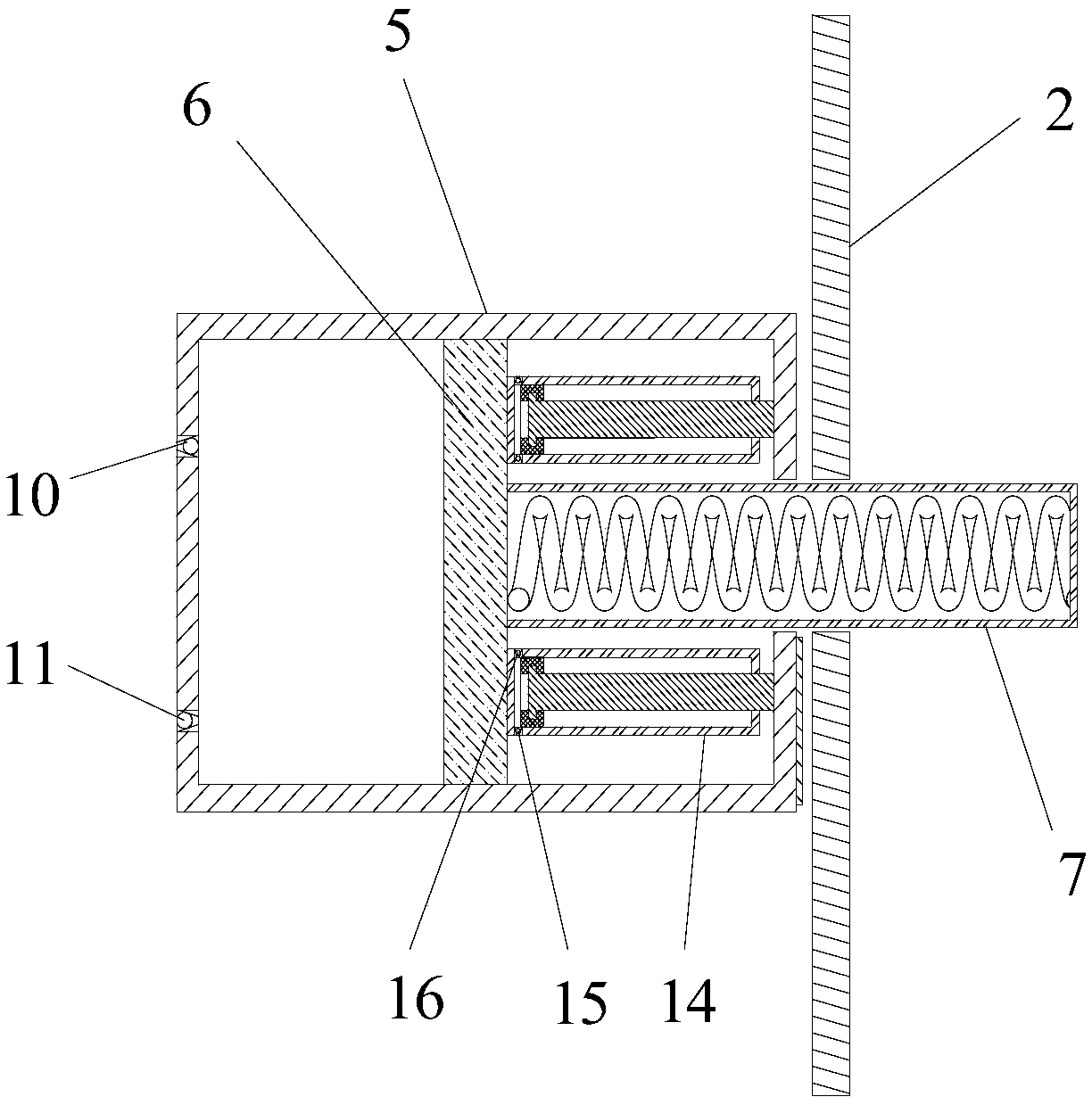

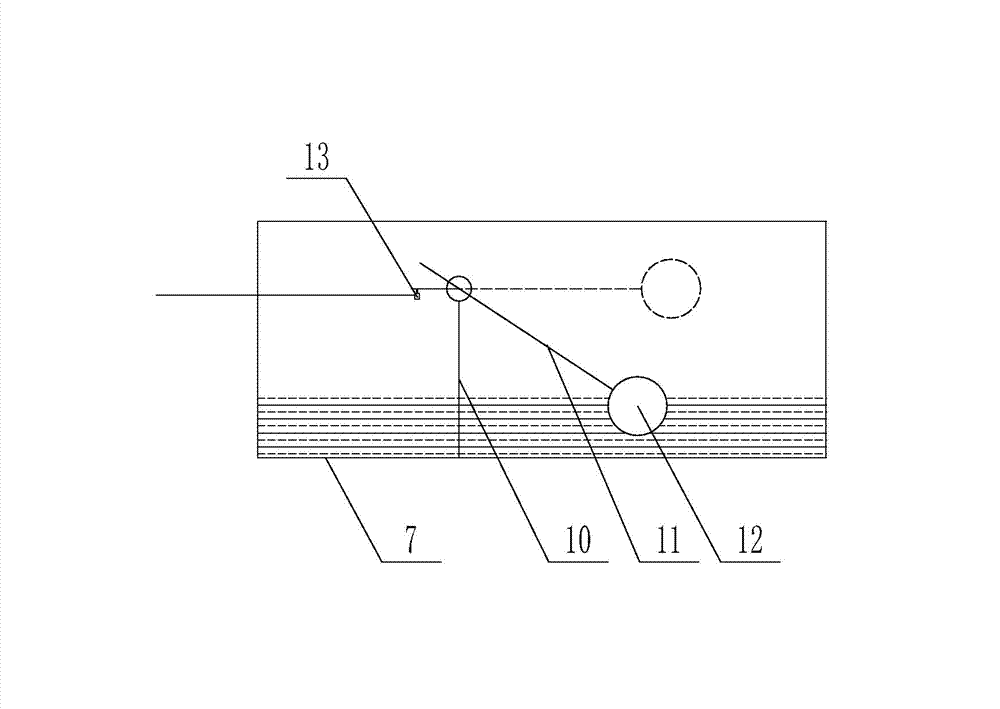

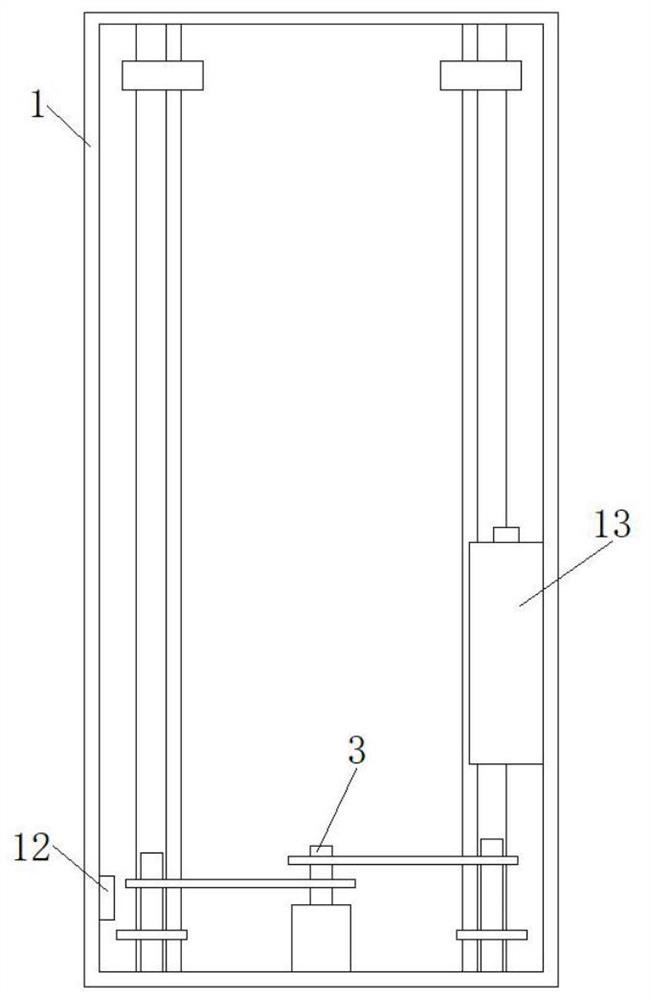

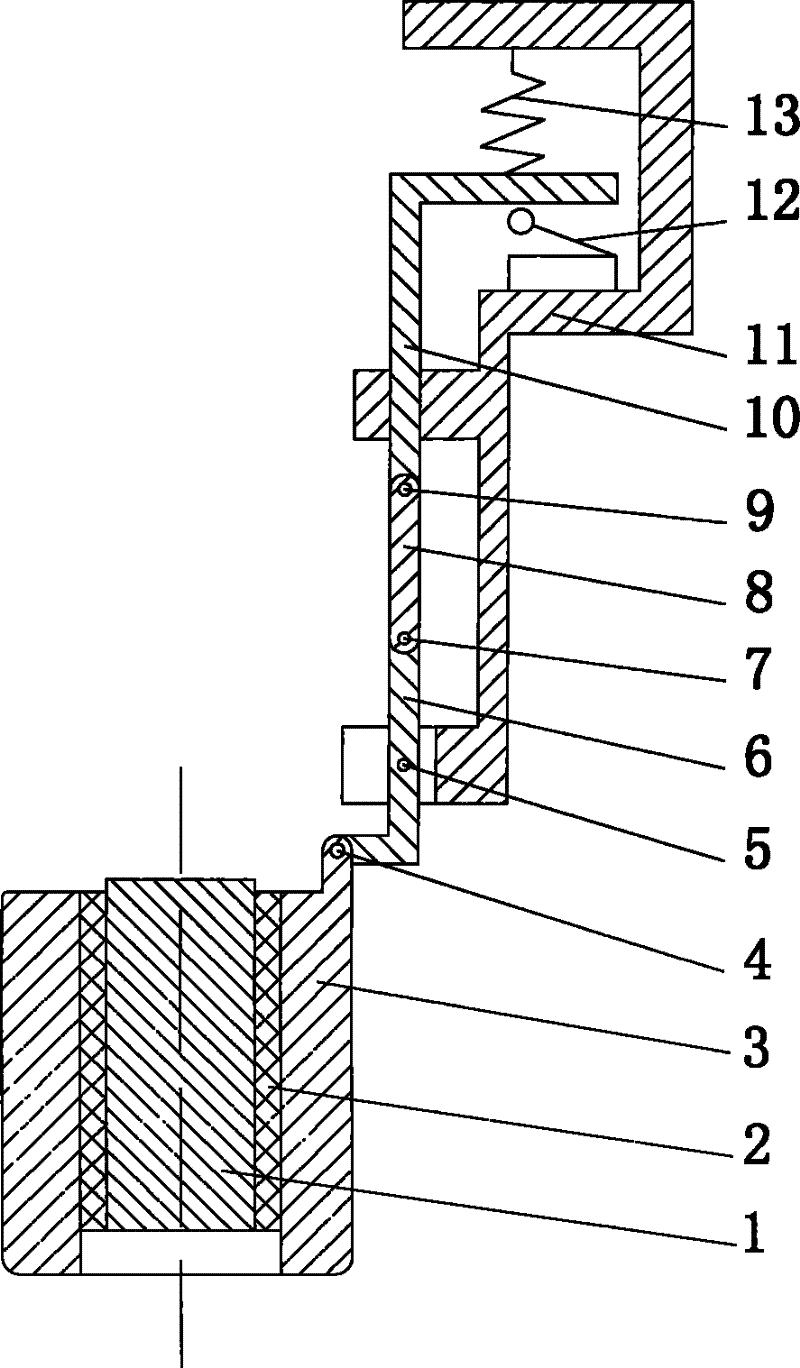

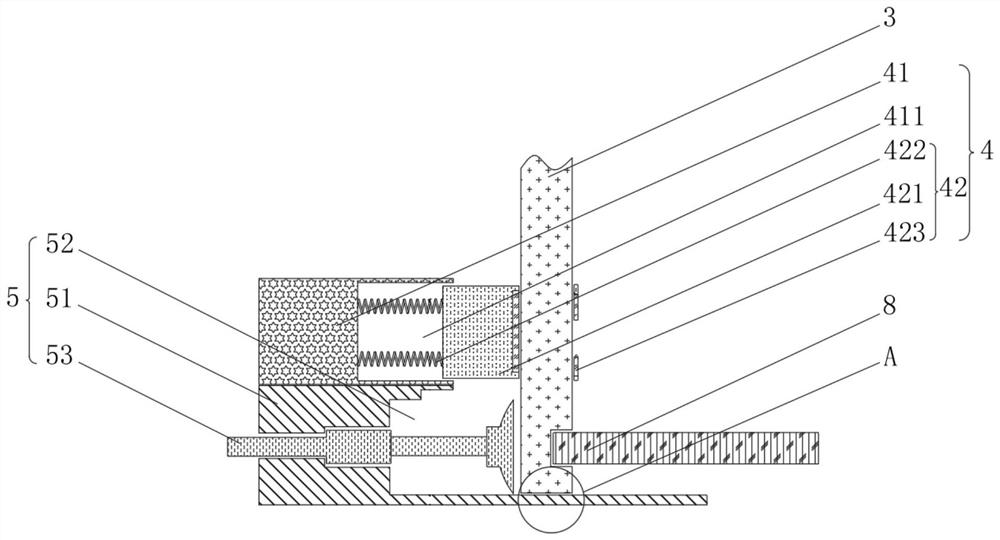

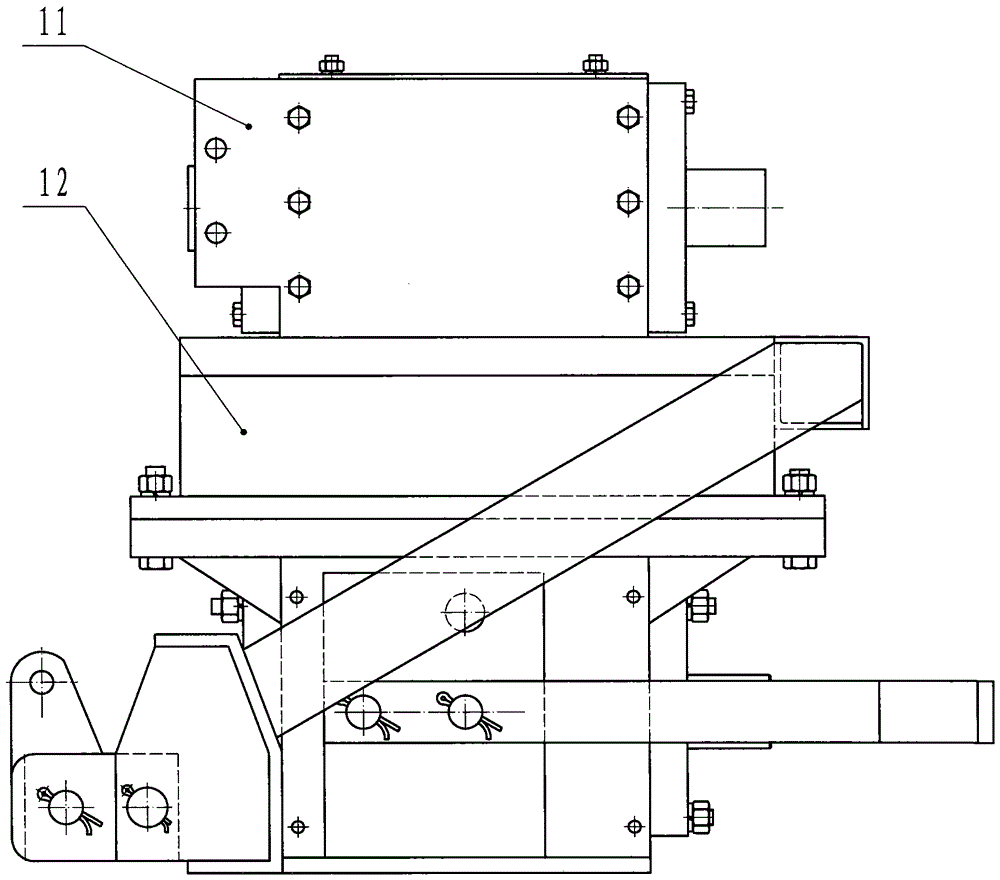

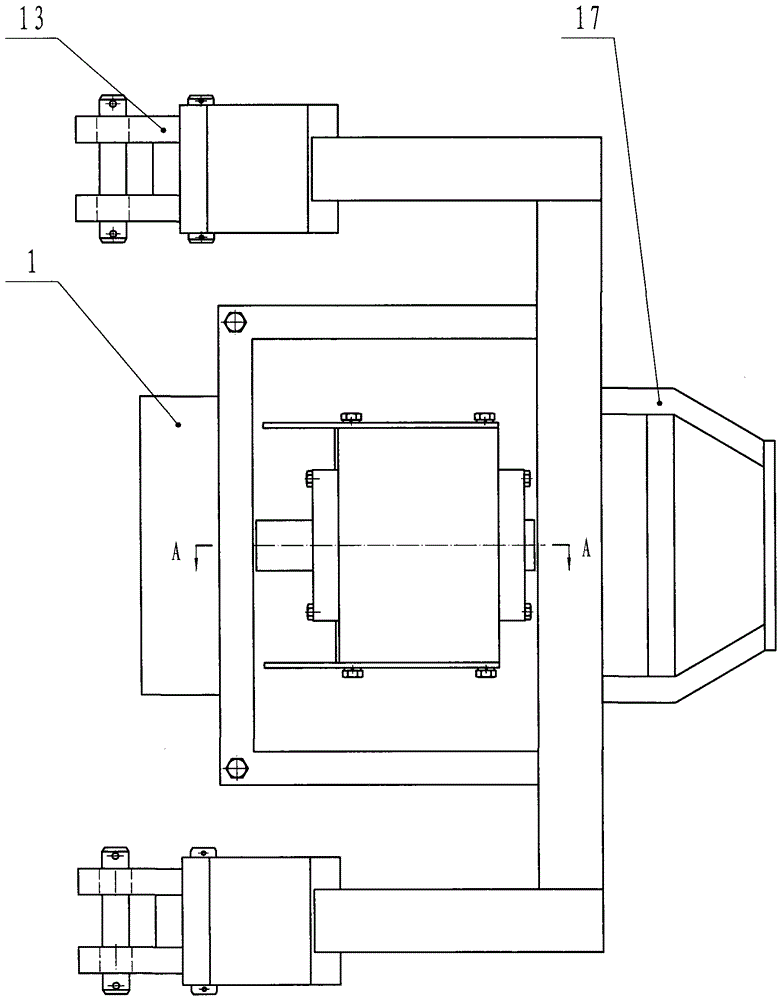

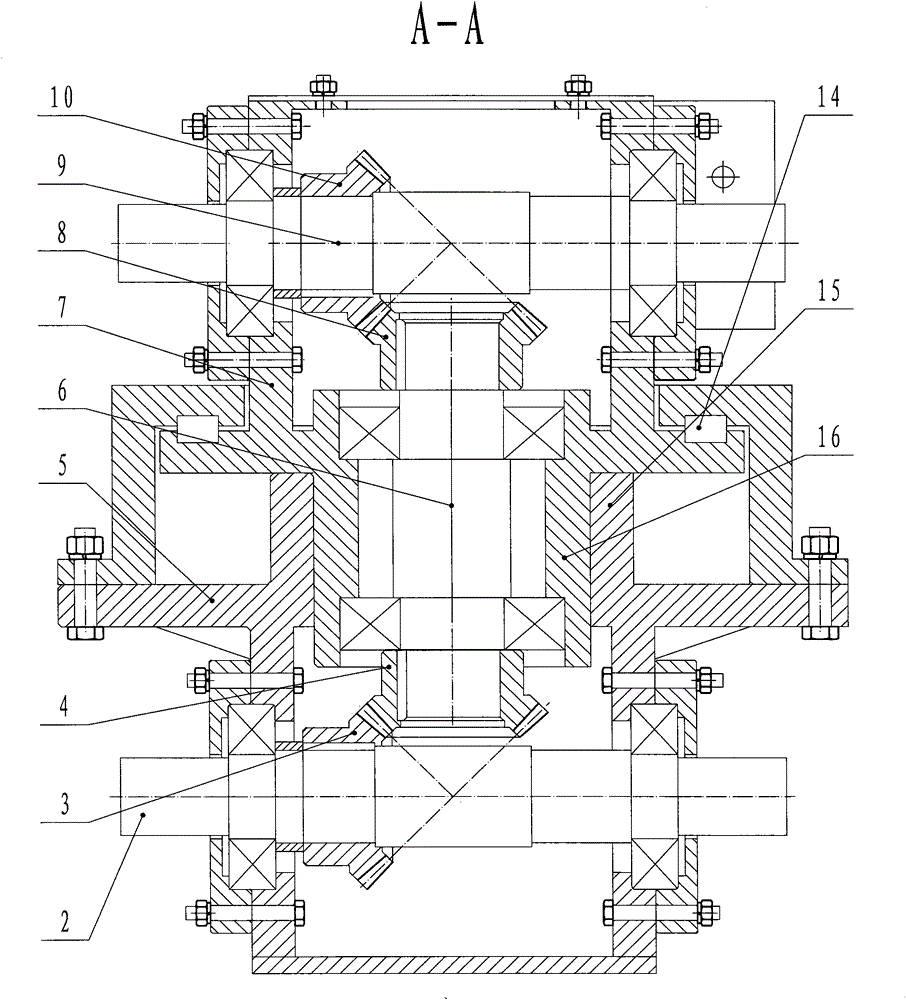

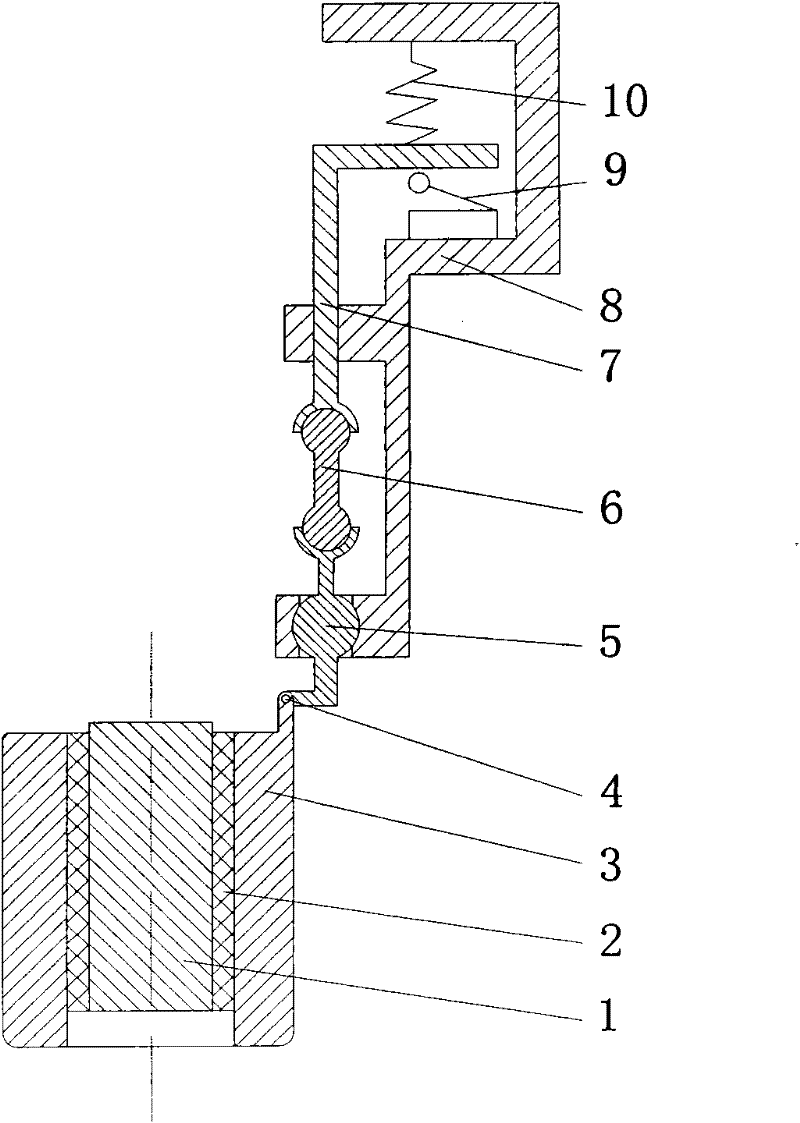

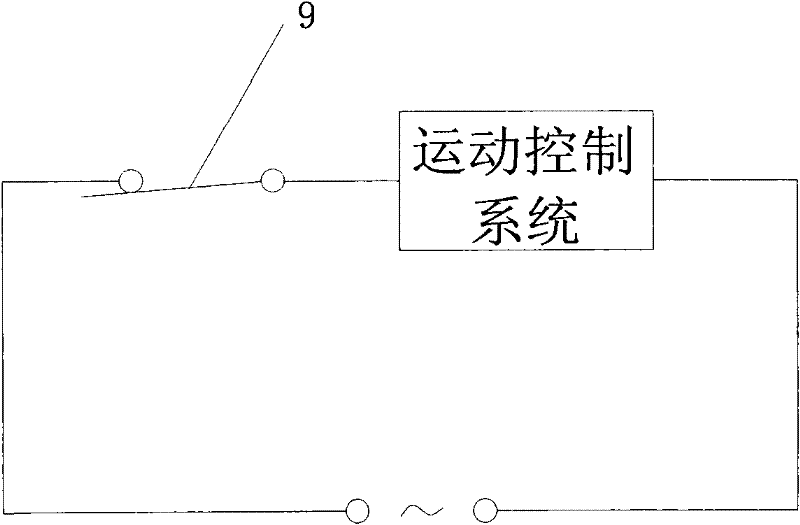

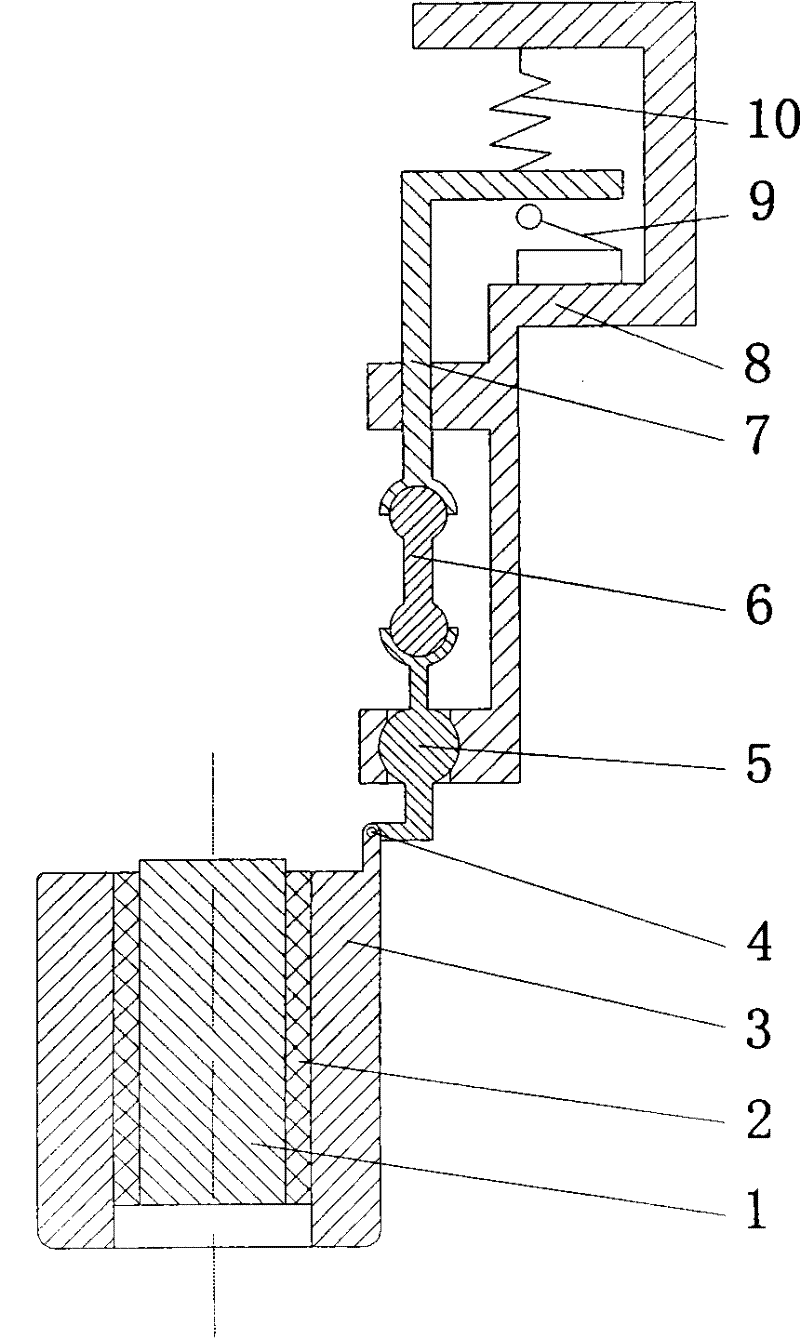

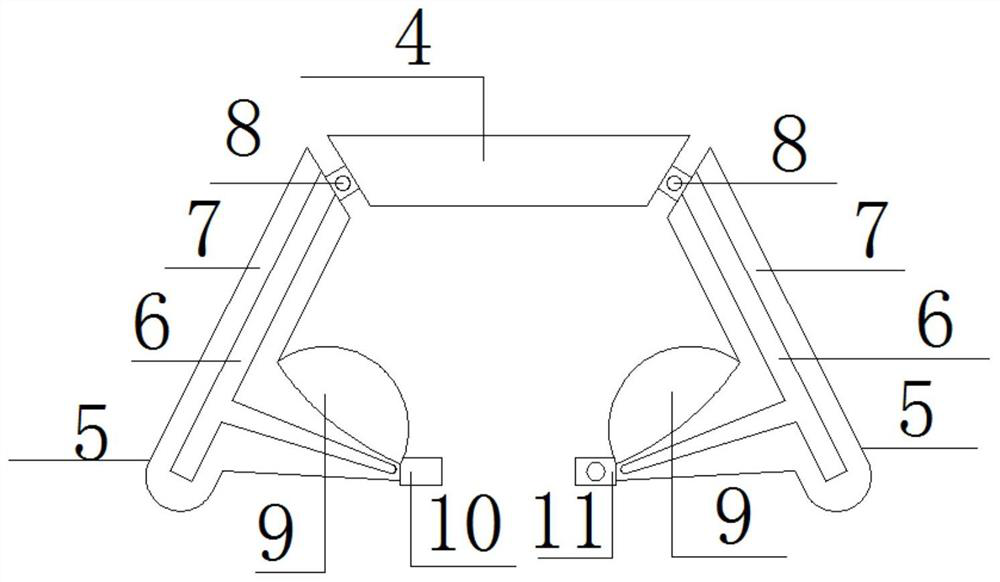

Anti-collision device of automatic ultrasonic flaw detection system

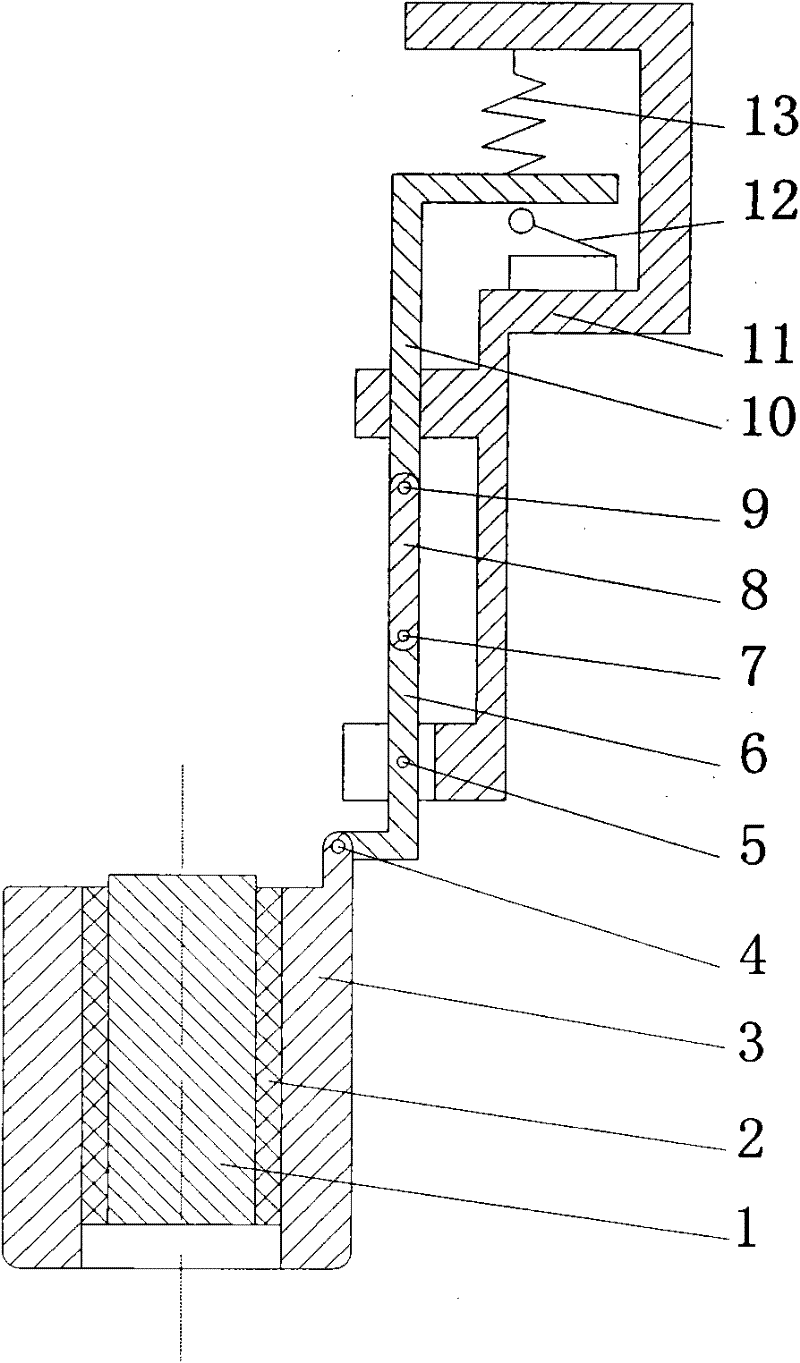

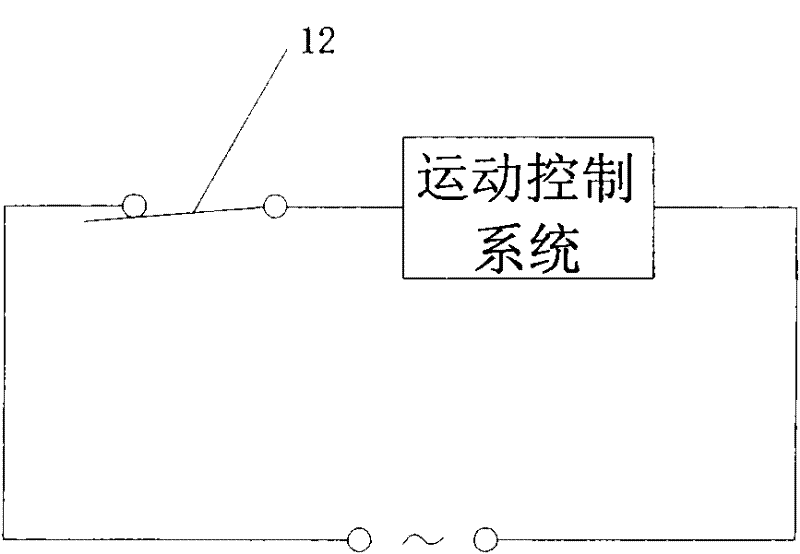

InactiveCN101852777AFrom impactMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringMotion system

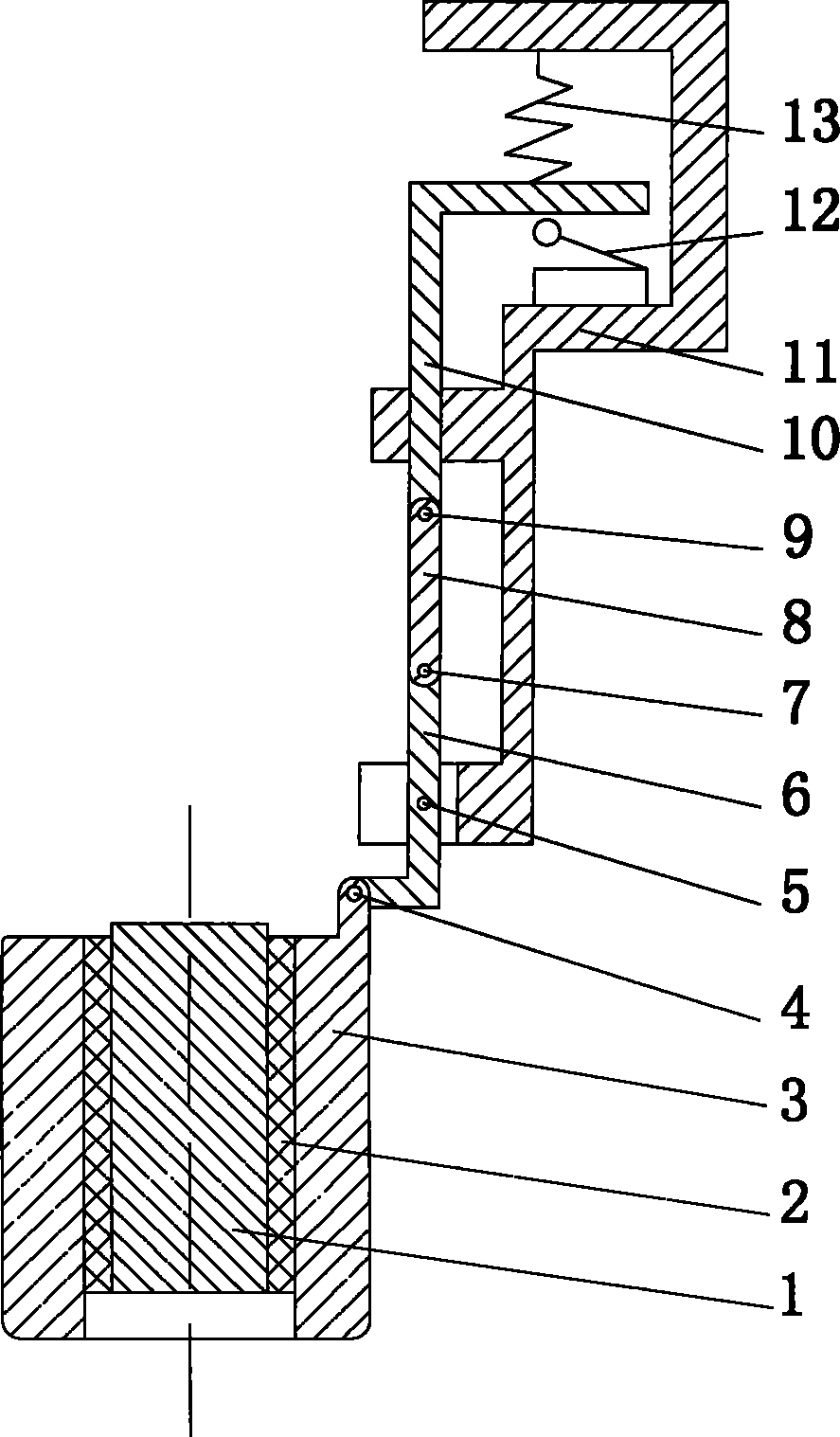

The invention discloses an anti-collision device of an automatic ultrasonic flaw detection system. An elastic element is sleeved outside a probe, and a protection cover is sleeved outside the elastic element. The upper end of the protection cover is connected with one end of a first connecting rod through a first hinge. The middle part of the first connecting rod is connected with one end of a mounting bracket through a second hinge. The other end of the first connecting rod is connected with one end of a second connecting rod through a third hinge. The other end of the second connecting rod is connected with one end of an inverted L-shaped connecting rod through a fourth hinge. The inverted L-shaped connecting rod is sleeved on the middle part of the mounting bracket, and the upper end face of the inverted L-shaped connecting rod is suspended at the inner side face of the mounting bracket through a spring. The lower end face of the inverted L-shaped connecting rod is connected with a micro-switch contact fixed in a fixed mount. When a foreign body hits the protection cover, the protection cover drives the first connecting rod to rotate around the second hinge so as to drive the second connecting rod to deflect a certain angle and drive the third connecting rod to move downwards to touch the micro-switch, then the moving system is stopped automatically so as to stop the movement of the probe to avoid collision of the expensive probe.

Owner:ZHEJIANG UNIV

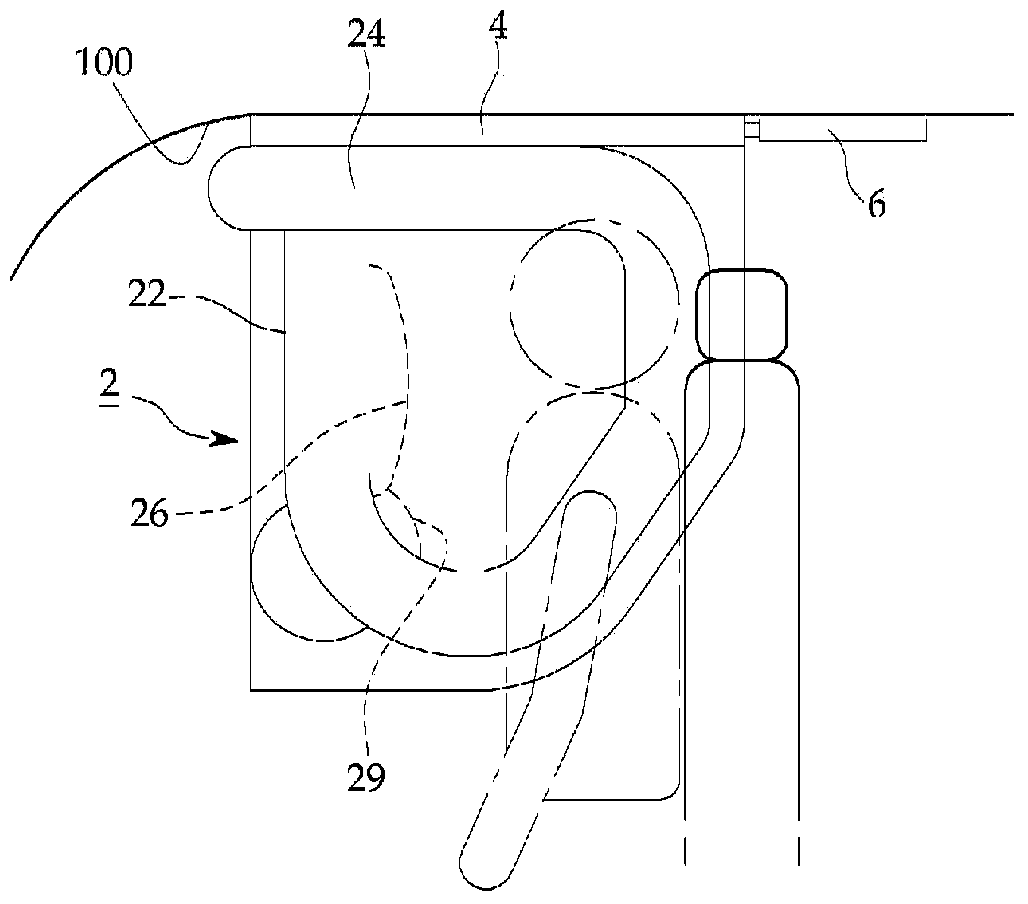

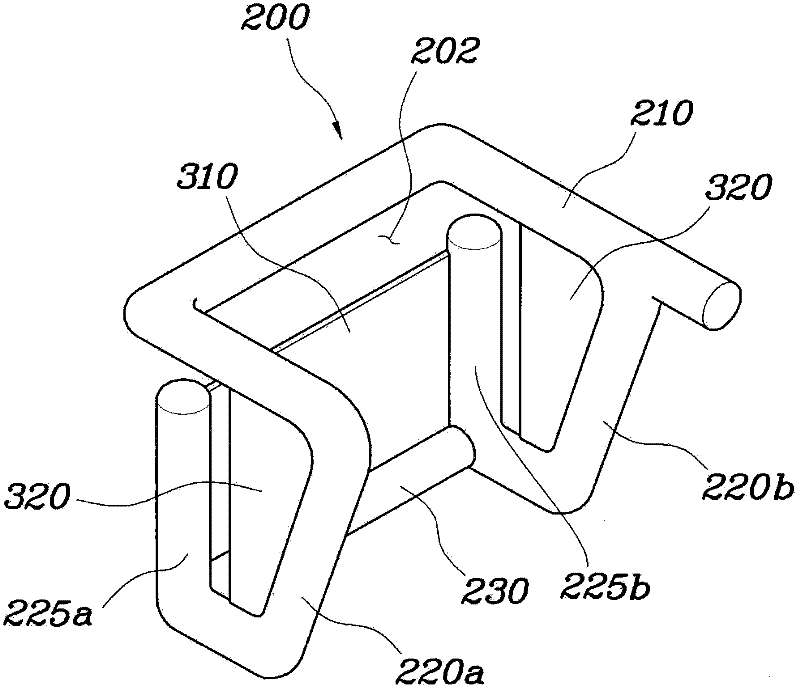

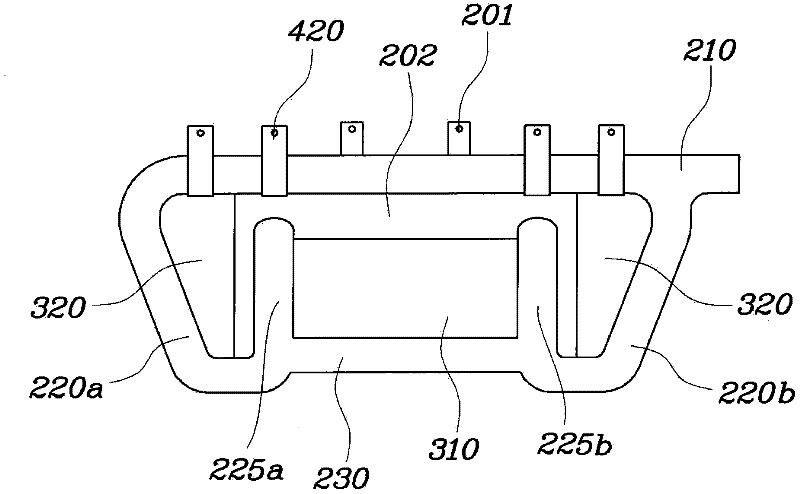

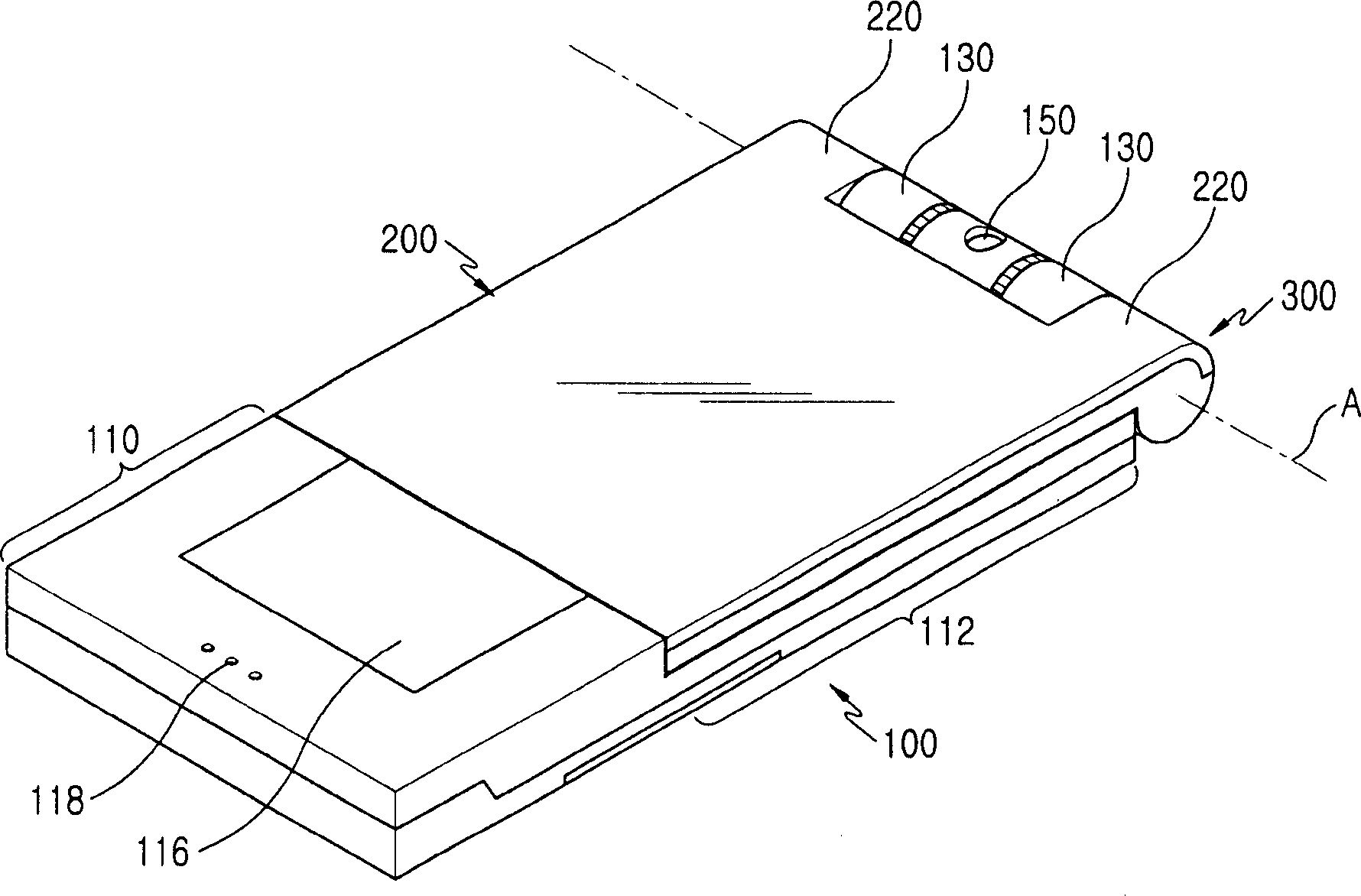

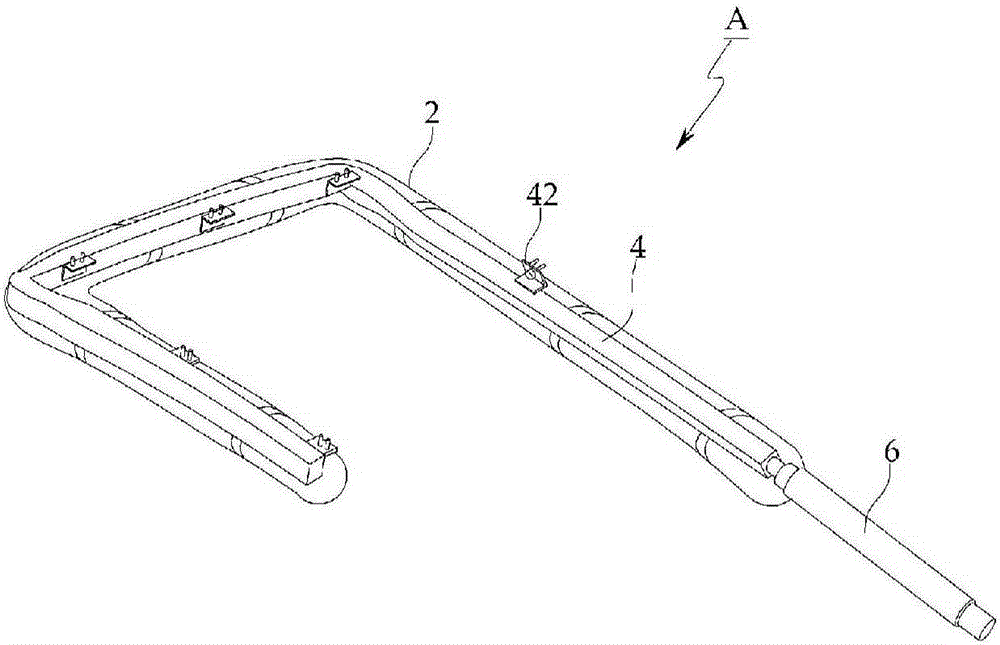

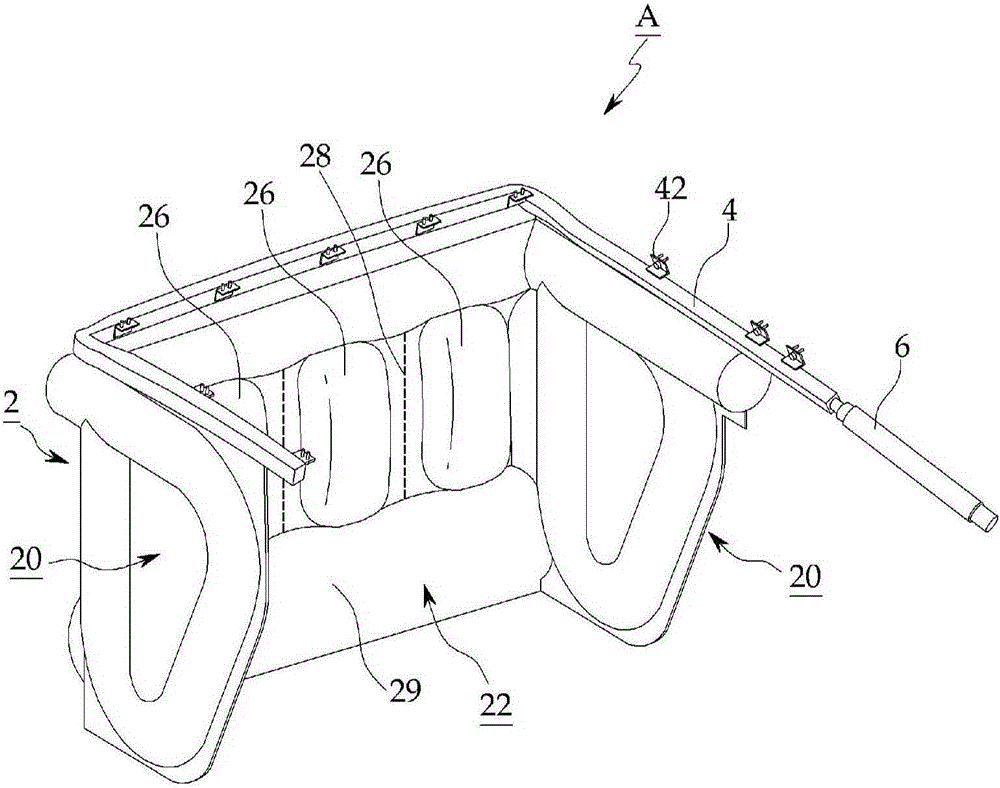

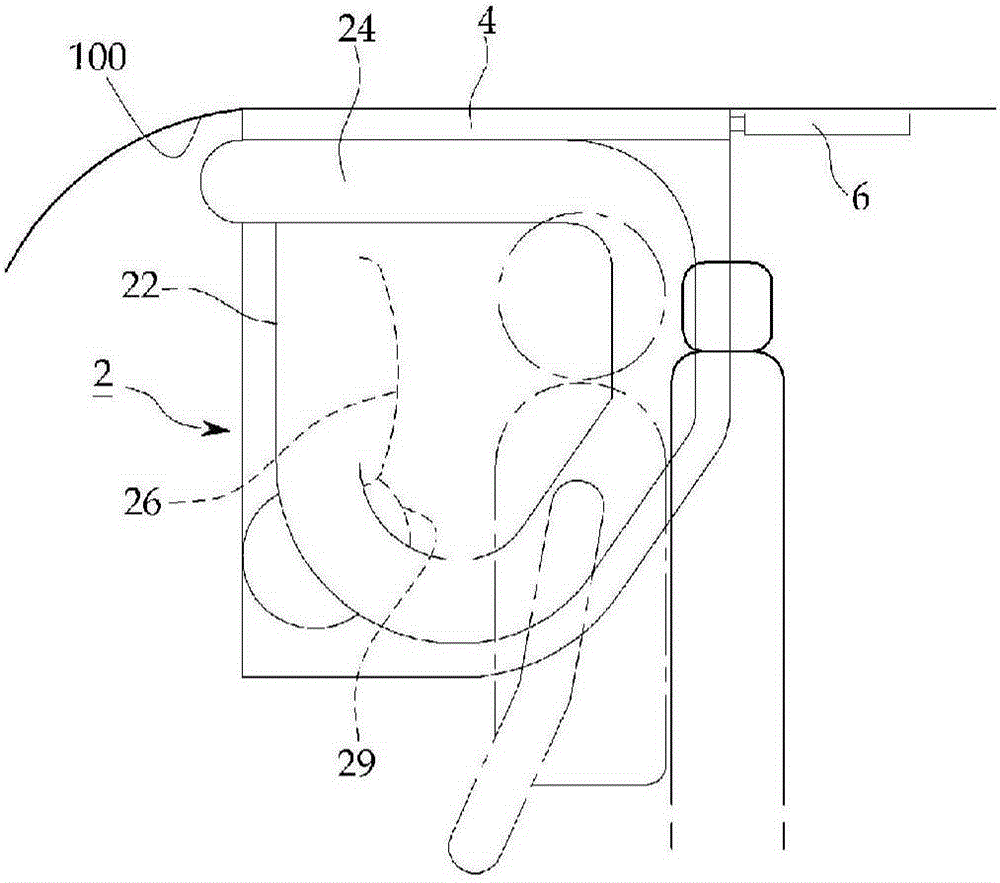

Unification airbag module

Disclosed is a unification airbag module. The unification airbag module includes a cushion to protect a front and a side of an occupant, a fixing member mounted on a ceiling of a vehicle and formed therein with a capacity such that the cushion is rolled and received in the cavity, and an inflator supplying inflation gas to the cushion. The cushion includes a front portion corresponding to a head and a chest of the occupant, and a side portion corresponding to both sides of the head and the chest of the occupant. A main chamber is formed on edges of the front and side portions, and a plurality of sub-chambers communicating with the main chamber are formed at the front portion and the side portion. The occupant is completely surrounded by the unification airbag module so that the occupant is protected from the front collision and the side collision.

Owner:AUTOLIV DEV AB

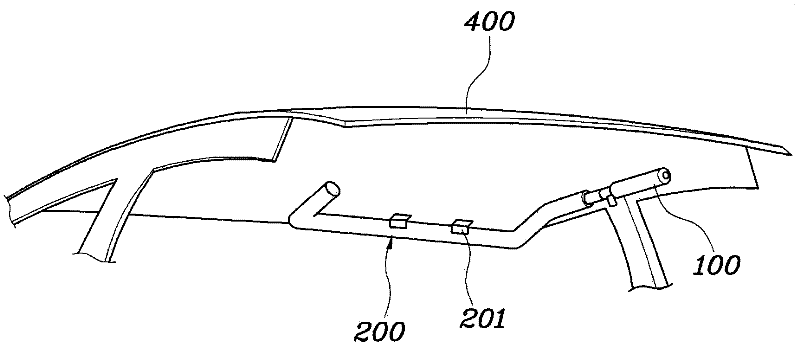

Roof airbag apparatus for vehicle

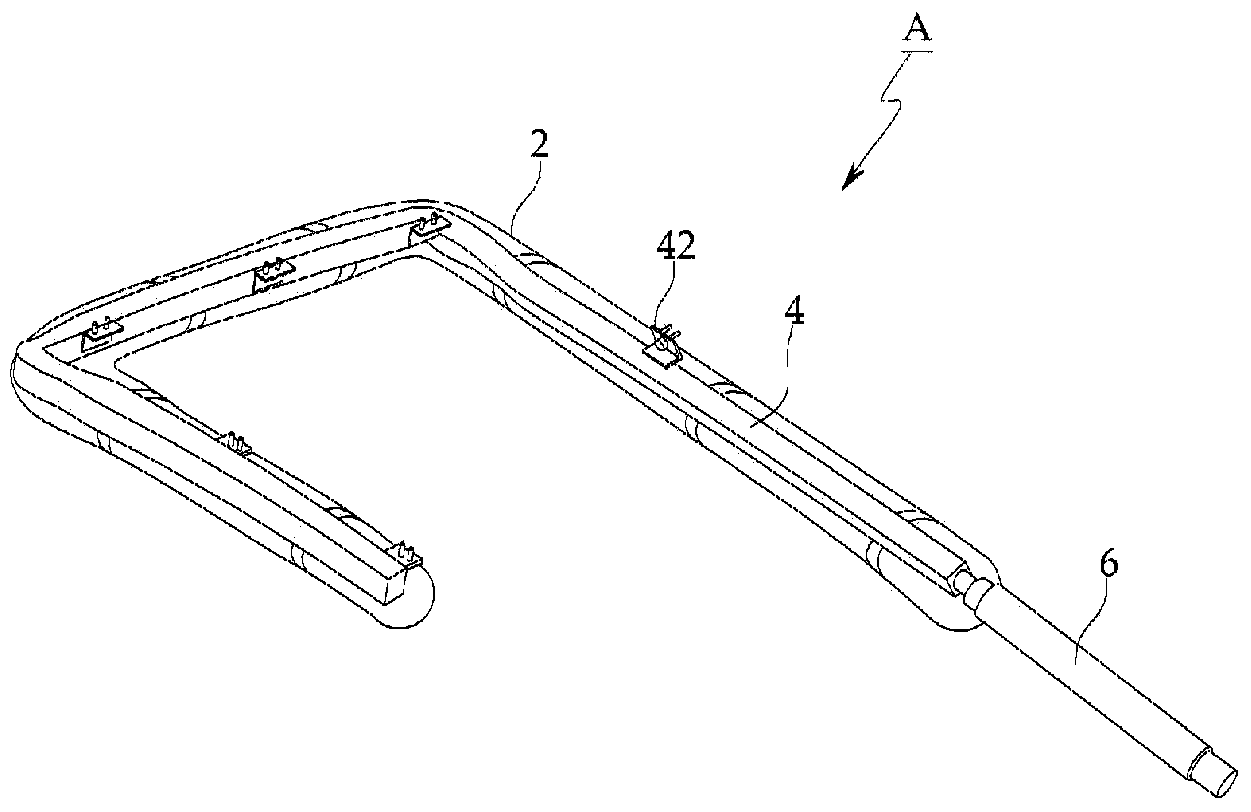

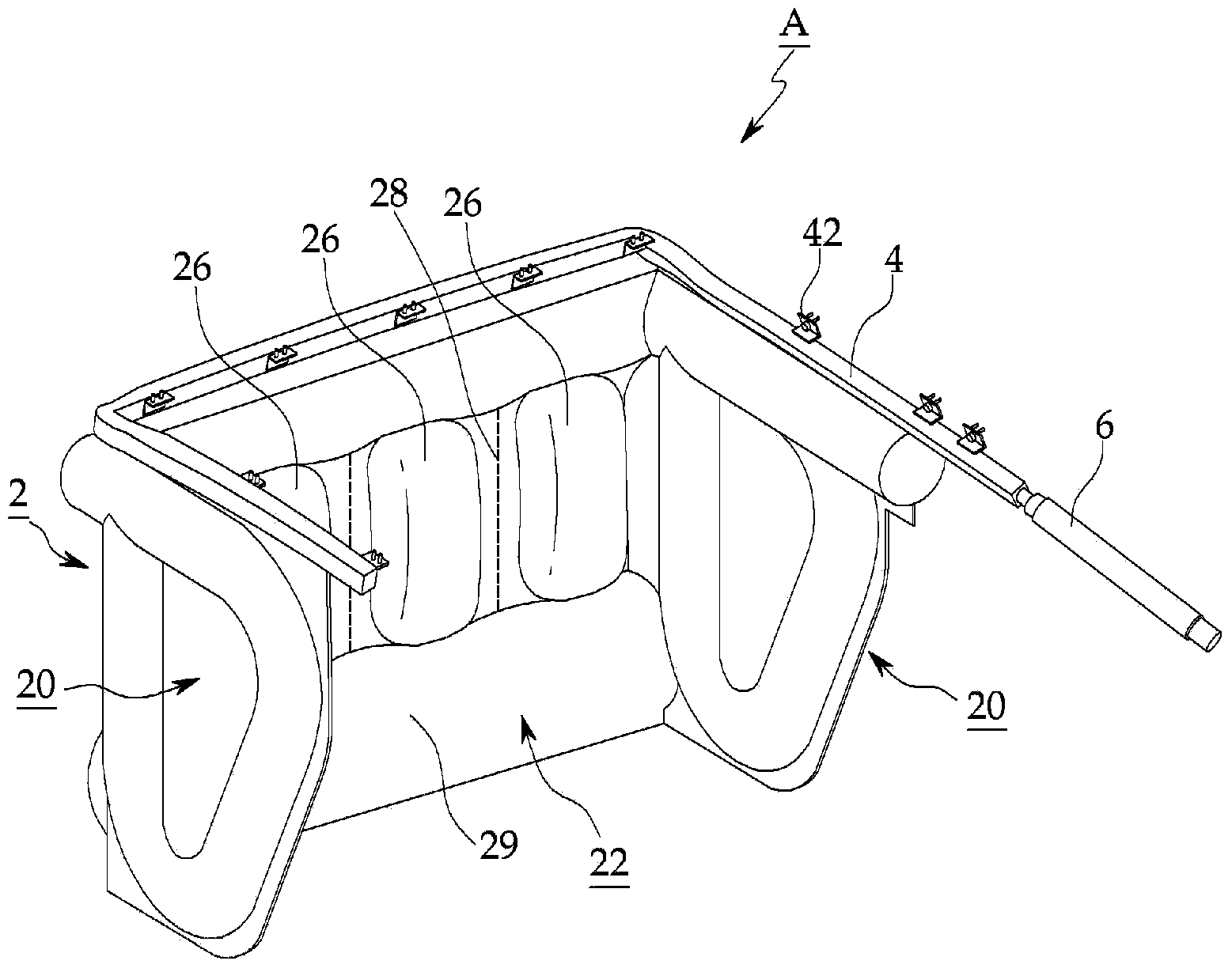

InactiveCN102463957AFrom impactReduce weightPedestrian/occupant safety arrangementAirbagGas pressure

A roof airbag apparatus for a vehicle, may include an inflator providing gas pressure, an air tube deploying towards sides of a passenger sitting on a seat when gas may be supplied from the inflator into the air tube, and a front support panel provided on a front end of the air tube to enclose a front portion of the passenger when the air tube may be deployed.

Owner:HYUNDAI MOTOR CO LTD

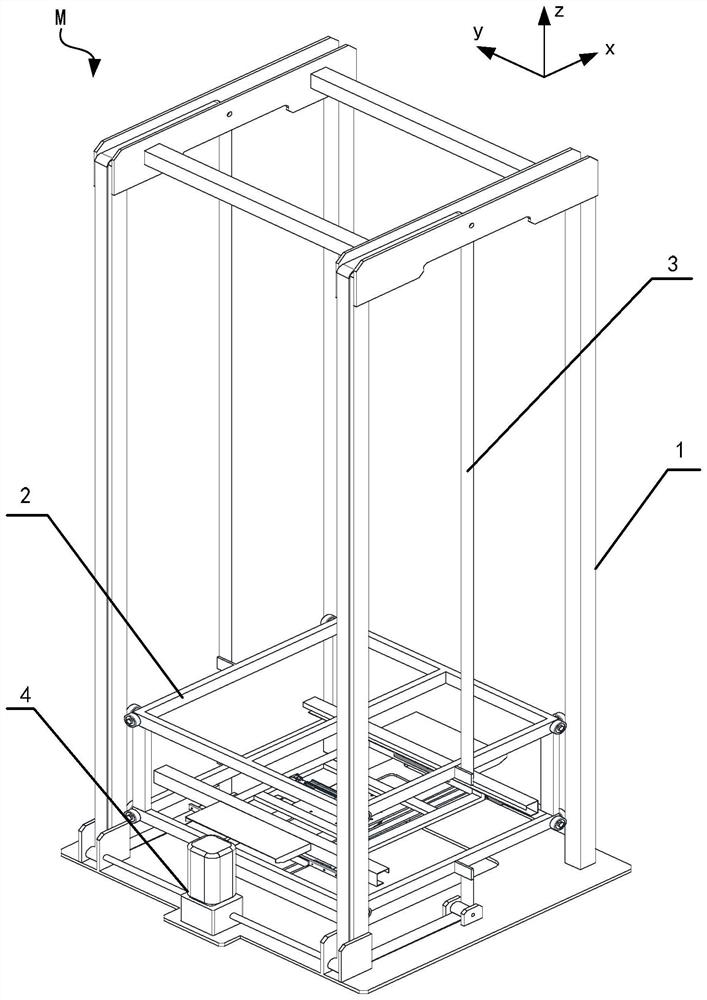

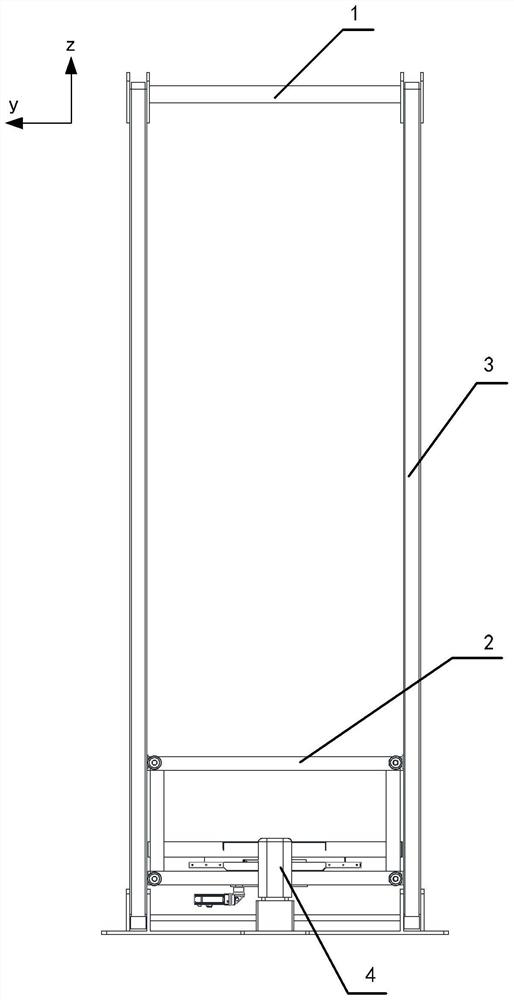

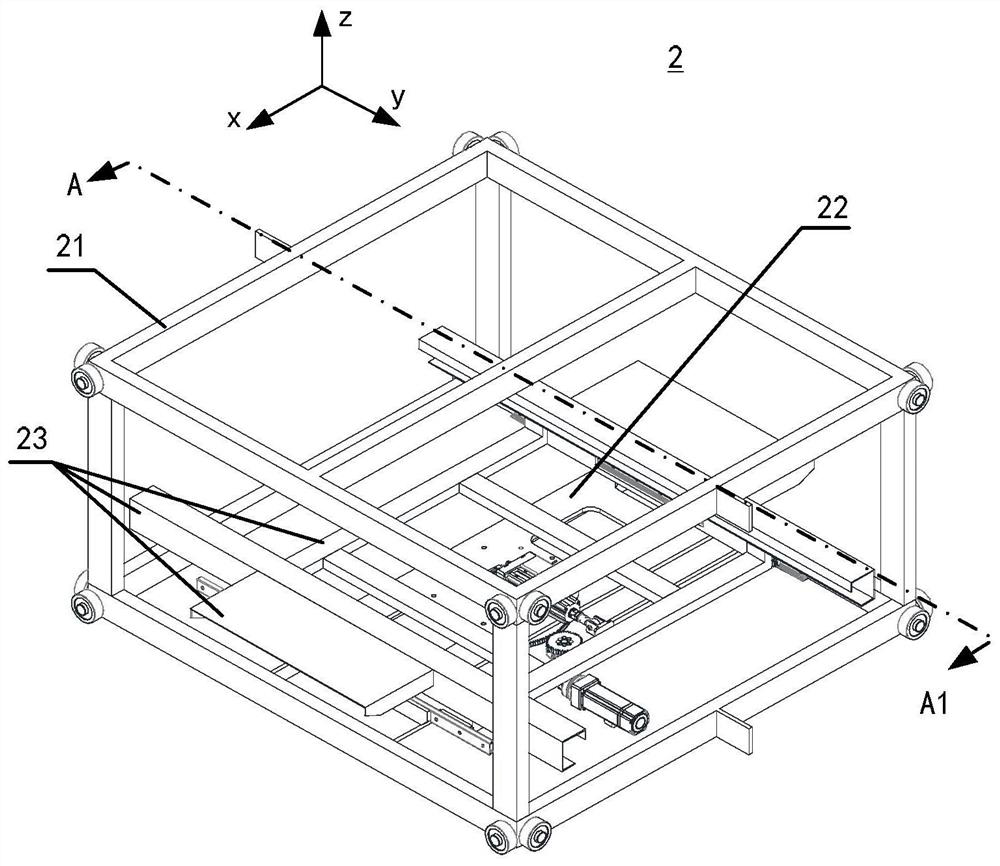

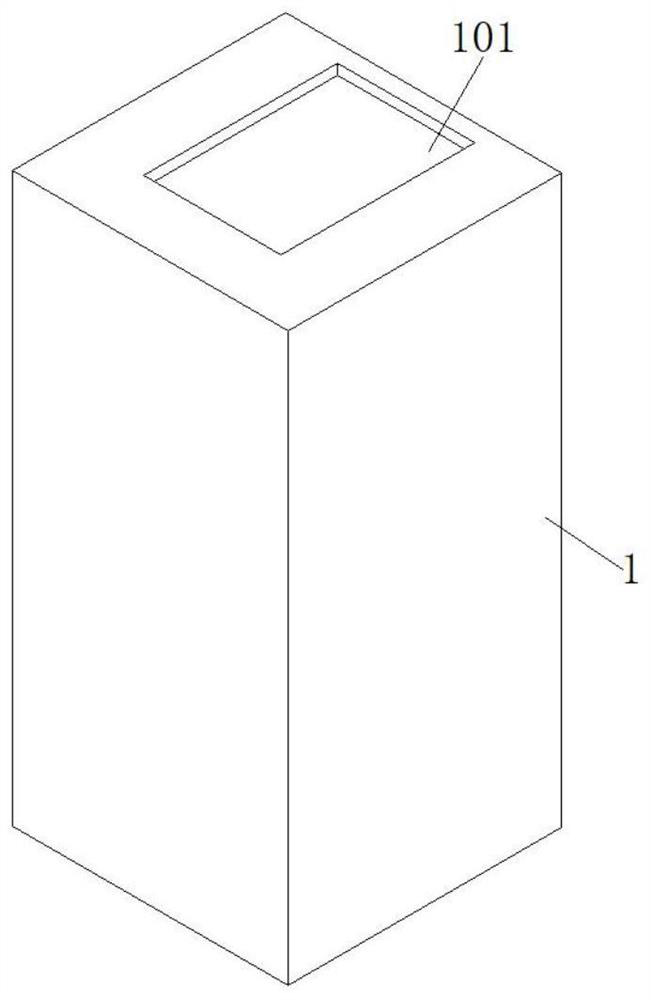

Shuttle vehicle layer-changing elevator for three-dimensional warehouse and shuttle vehicle transportation device

ActiveCN112320178ALimited movementReduce weightStorage devicesMechanical engineeringAerospace engineering

The invention discloses a shuttle vehicle layer-changing elevator for a three-dimensional warehouse and a shuttle vehicle transportation device. The shuttle vehicle layer-changing elevator comprises athree-dimensional supporting frame and a vehicle carrying device used for carrying a shuttle vehicle. A lifting driving piece is arranged on the three-dimensional supporting frame, and the lifting driving piece is used for driving the vehicle carrying device to move in the vertical direction. The vehicle carrying device is located in the three-dimensional supporting frame and comprises a main frame structure and a rotatable vehicle carrying structure arranged in the main frame structure. The shuttle vehicle layer-changing elevator for the three-dimensional warehouse has the lifting and rotating functions at the same time, can be suitable for a bidirectional shuttle vehicle, matched three-dimensional goods shelves and roadways are easy to arrange, and the bidirectional shuttle vehicle cantransport goods between different height layers of the same three-dimensional goods shelf and between different three-dimensional goods shelves.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

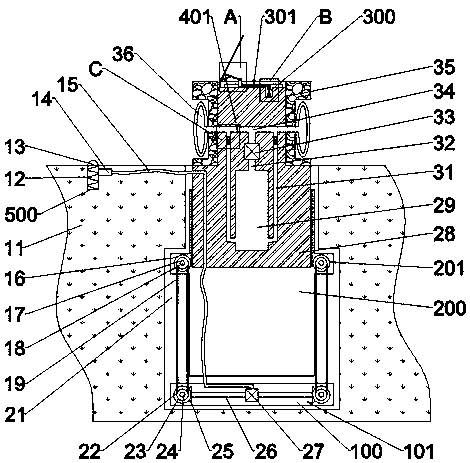

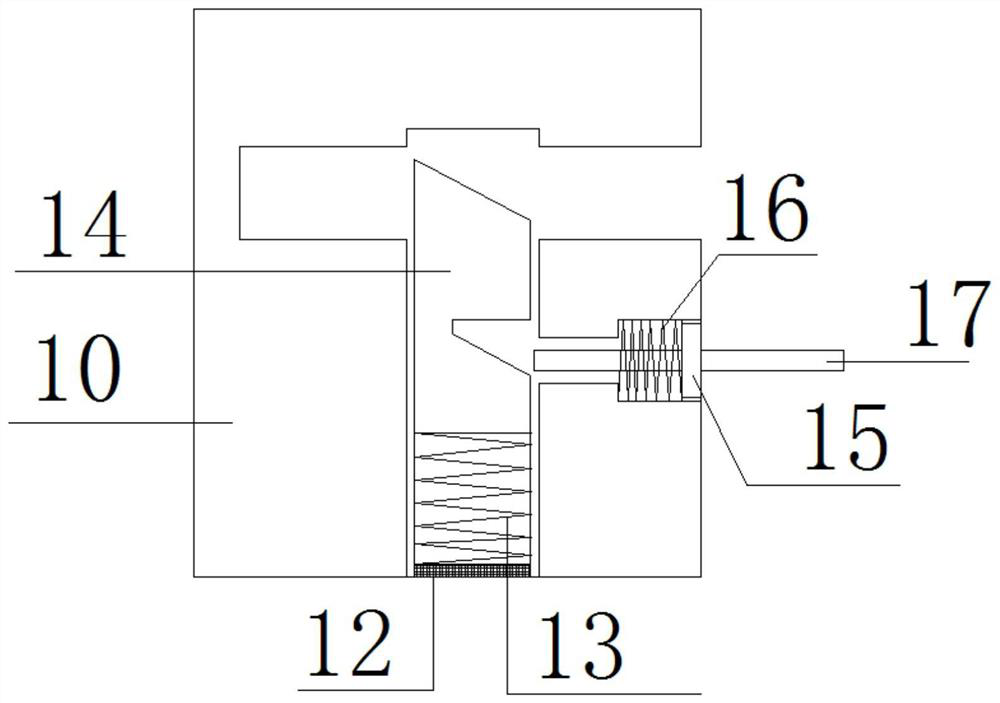

Crossroad pedestrian protection device

InactiveCN110359394AFrom impactProtection securityEmbedding padsRoadway safety arrangementsEngineeringRoad surface

The invention discloses a crossroad pedestrian protection device. The device comprises a road surface, a monitoring cavity is formed in the road surface, the bottom end face of the monitoring cavity is fixedly provided with a monitoring spring, the top end of the monitoring spring is fixedly provided with a monitoring switch, the right wall face of the monitoring cavity is fixedly provided with astarter, the right end of the starter is connected with an electric wire, an anti-collision rod base is fixedly arranged at the position, in the road surface, on the right side of the monitoring cavity, and a power cavity is formed in the anti-collision rod base. The device is simple in structure, convenient to maintain and convenient to use. When it is detected that a vehicle out of control rushes at the pedestrians on the crossroad, rapid automatic rising is carried out, protection is provided, the pedestrians on the crossroad are free of impact of the vehicle out of control, meanwhile, thevehicle out of control is rapidly forced to be parked, the serious accident can be prevented, and safety of persons on the vehicle can be indirectly protected.

Owner:SHANDONG JIUZHOU AUTOMOBILE MFG

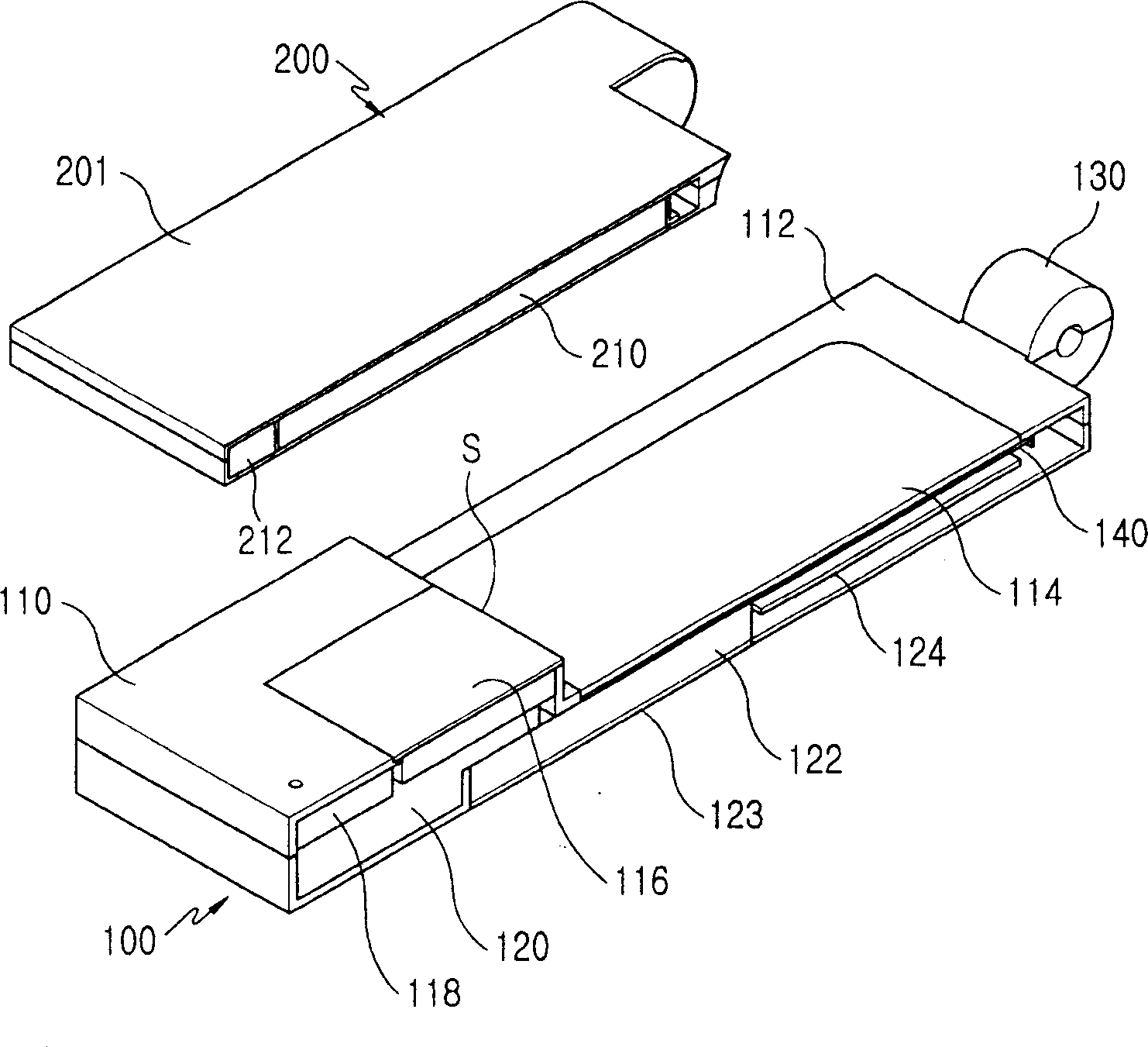

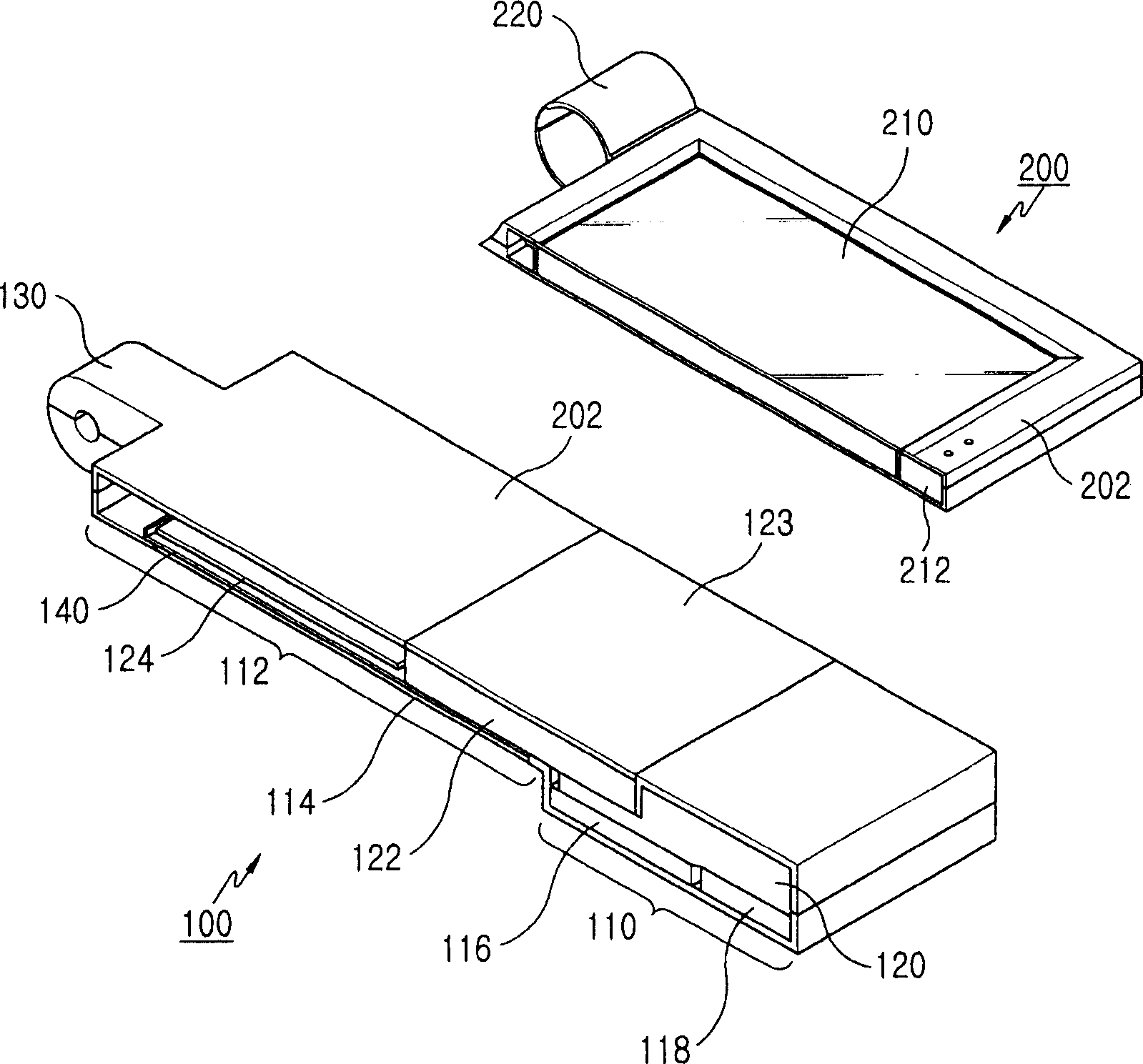

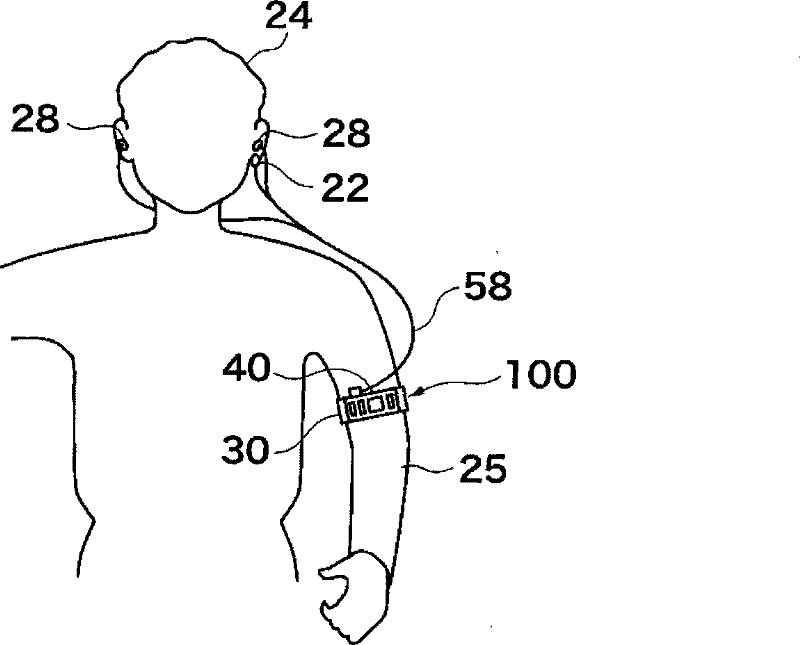

Slim portable terminal

InactiveCN1905577AEasy to carryEasy to thinRadio/inductive link selection arrangementsTelephone set constructionsBiomedical engineering

Owner:SAMSUNG ELECTRONICS CO LTD

Vehicle and anti-collision structure thereof

ActiveCN111086471AEffective protectionFrom impactBumpersAutomotive engineeringStructural engineering

Owner:BEIQI FOTON MOTOR CO LTD

Vertical shaft rotation type drawing mechanism for forage grass cutting flatting mill

InactiveCN104074924AReduce frictionFrom impactHarvestersToothed gearingsTransmitted powerEngineering

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

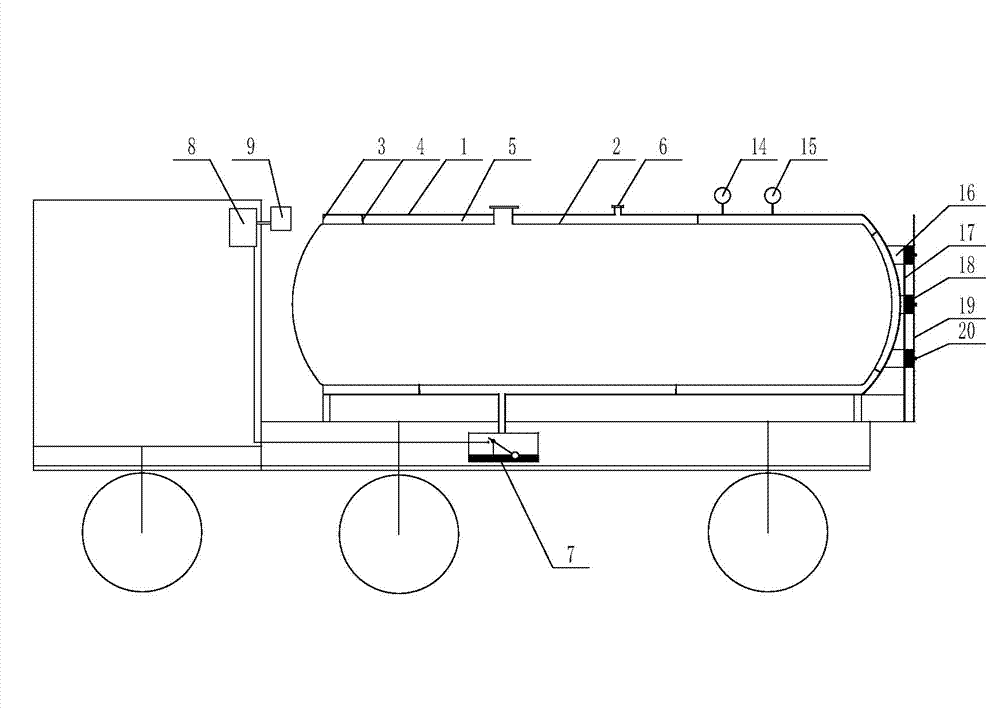

Tank body protecting device for flammable and combustible liquid transport vehicle

Owner:苏州盛天力离心机制造有限公司

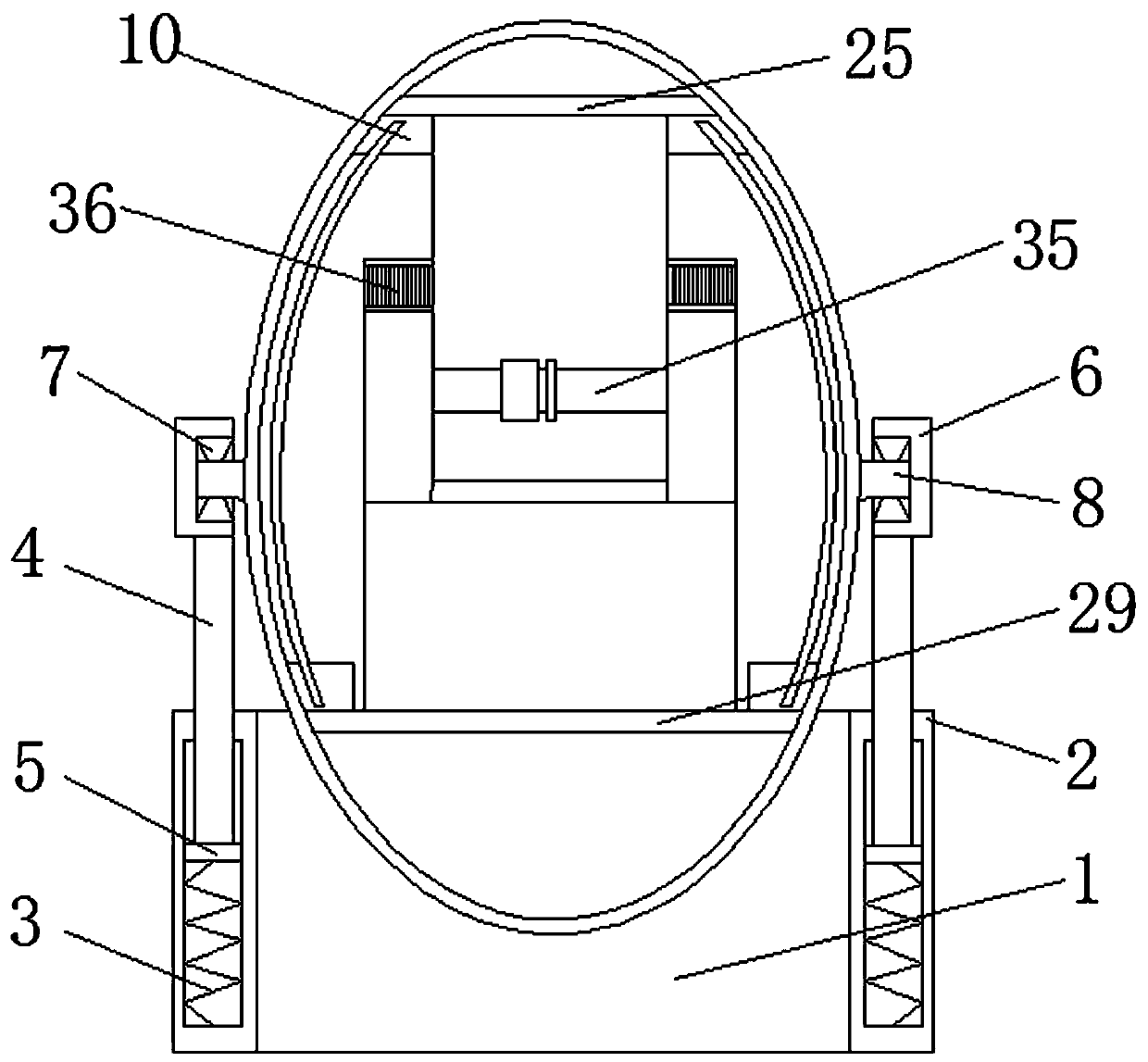

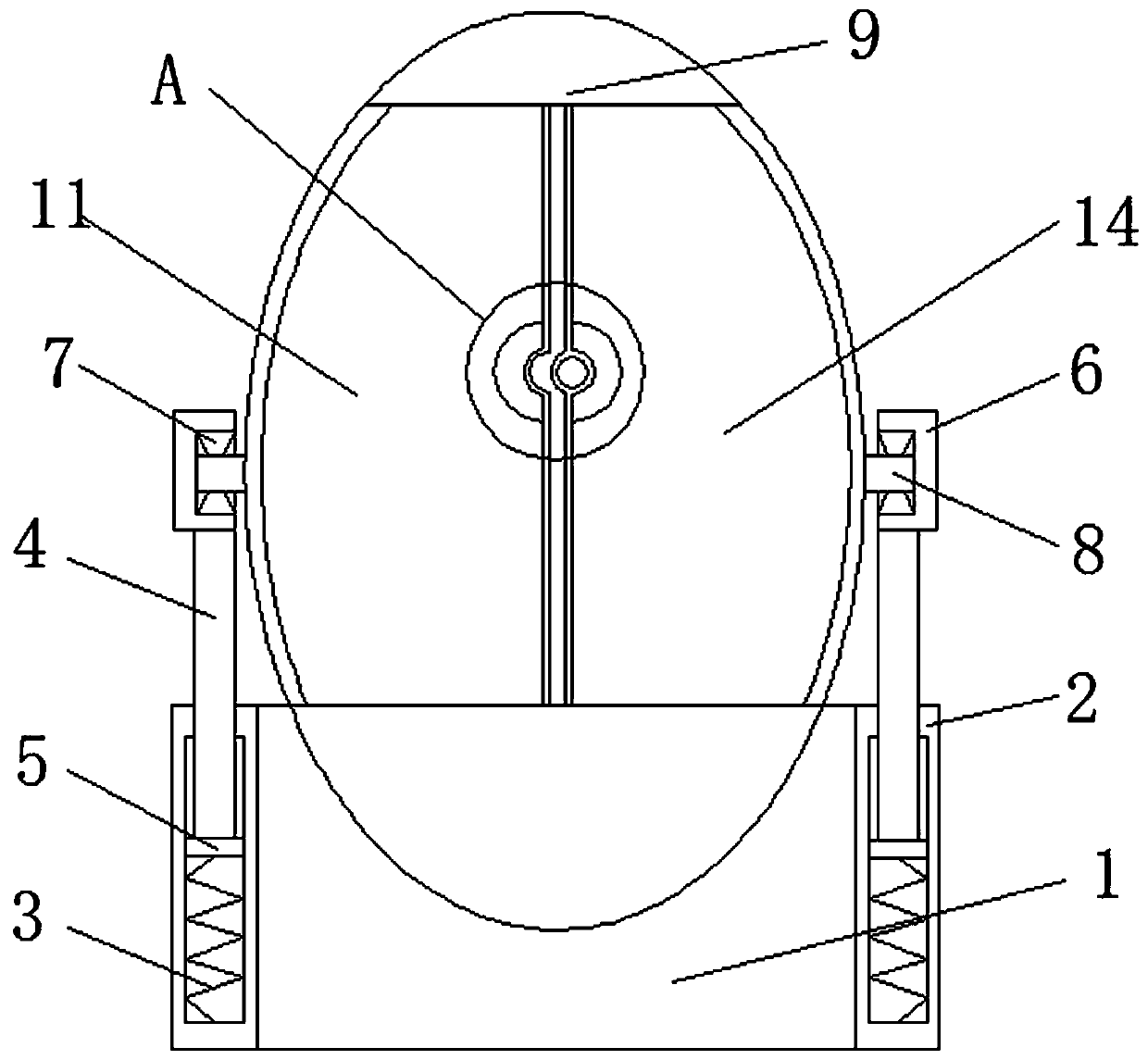

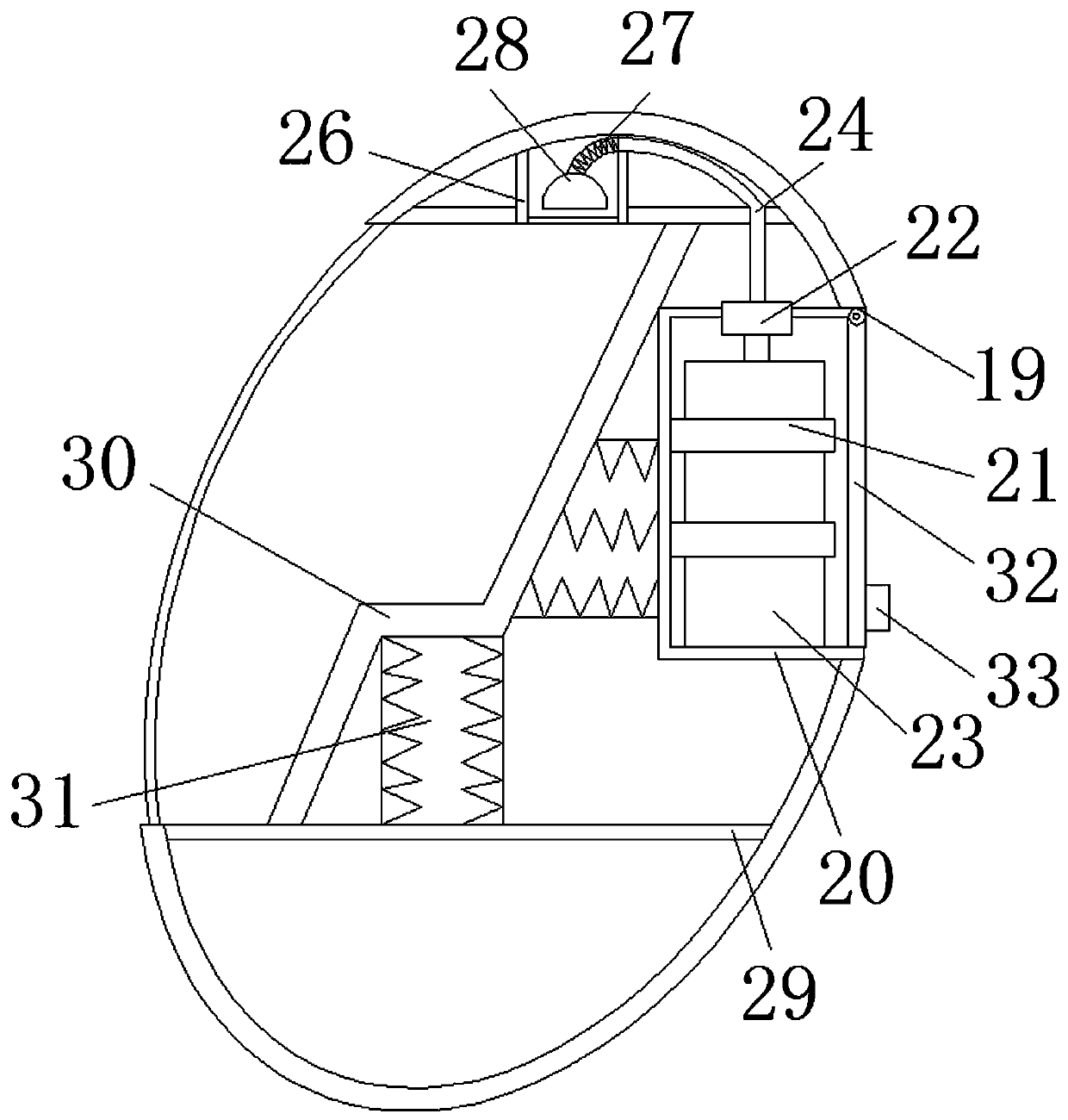

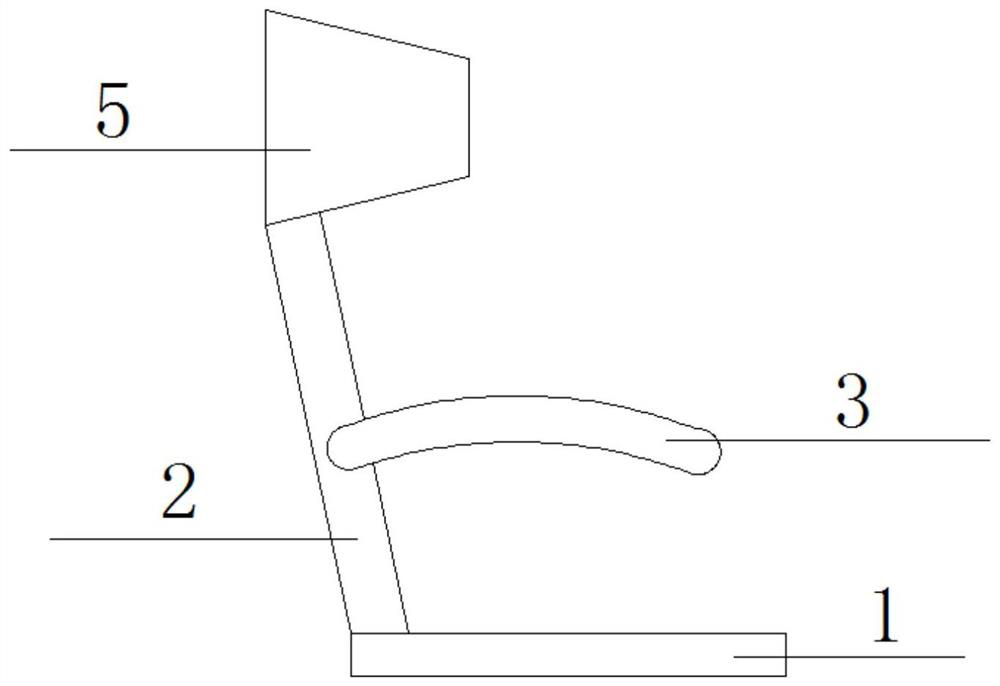

Intelligent aviation seat

InactiveCN110143286AReduce harmFrom impactSeating arrangementsEmergency oxygen systemsAviationGeotechnical engineering

The invention belongs to the technical field of aviation equipment and in particular relates to an intelligent aviation seat. The intelligent aviation seat comprises a base; telescopic casings are fixedly connected to the surfaces of the two sides of the base; buffering springs are fixedly connected to the internal bottom walls of the telescopic casings; telescopic rods are slidingly inserted in the internal walls of the telescopic casings; limiting blocks are fixedly connected to one ends of the telescopic rods; the surfaces of the limiting blocks are slidingly inserted in the internal wallsof the telescopic casings; the lower surfaces of the limiting blocks are fixedly connected with one ends of the buffering springs; supporting seats are fixedly connected to the other ends of the telescopic rods; bearings are fixedly connected to the internal walls of the supporting seats; rotating shafts are fixedly connected to the inner rings of the bearings; and shells are fixedly connected toone ends of the two rotating shafts. According to the intelligent aviation seat, as the telescopic casings are fixedly connected to the surfaces of the two sides of the base, the buffering springs arefixedly connected to the internal bottom walls of the telescopic casings, and the telescopic rods are slidingly inserted in the internal walls of the telescopic casings, the aircraft bumpiness and impact on an aircraft are reduced, and injuries to passengers are reduced.

Owner:郑培清

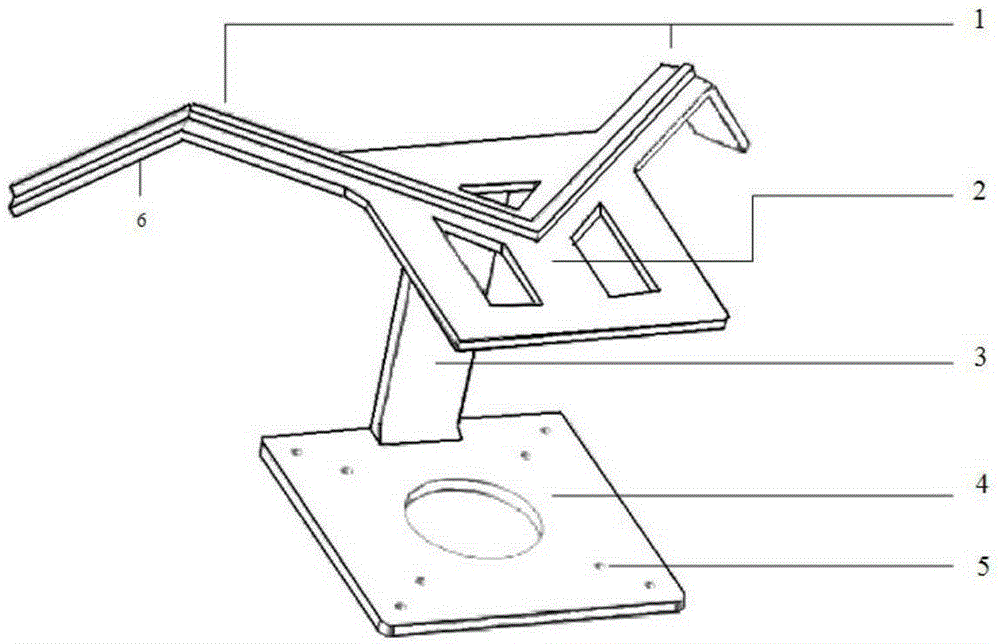

Airborne laser radar fixing device

InactiveCN106483528AEffectively fixedReduce weightElectromagnetic wave reradiationRadarOptoelectronics

The invention relates to a fixing device applicable to radar mounted on a small unmanned aerial vehicle, and specifically relates to an airborne laser radar fixing device. Laser radar, which is used as an environment perception unit, is equivalent to the eye of a demonstrator, and plays an important role in improving the independence ability of unmanned aerial vehicles. Laser radar is prone to damage by outside shock and collision because of a complex and precise internal structure. In order to solve the problems, the invention designs a fixing device for protecting and fixing laser radar. The device is light, stable in structure and reasonable in design, and can fix airborne laser radar effectively.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

Electric power facility safety warning pile based on alarm function

InactiveCN112878234AFrom impactPlay the role of sound and light alarmTraffic signalsRoad signsInfraredElectric machine

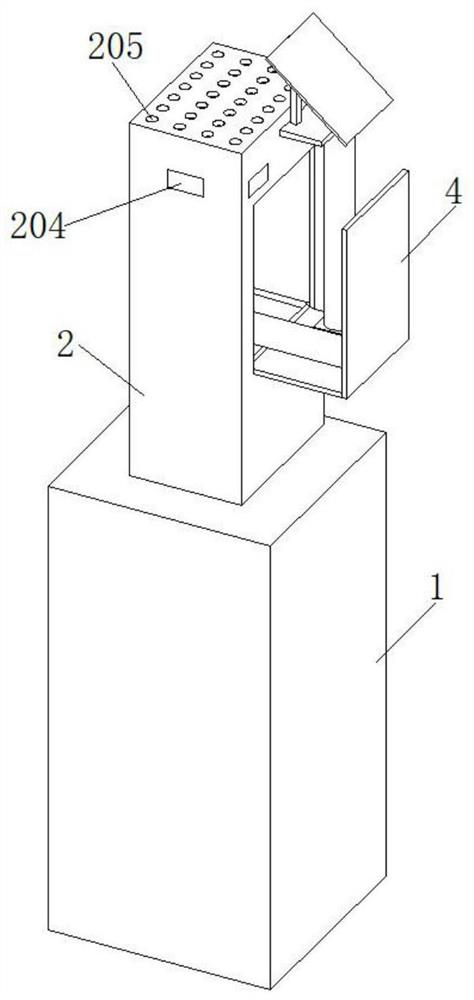

The invention discloses an electric power facility safety warning pile based on an alarm function, and relates to the technical field of electric power facility warning. An upper pile shell capable of downwards sliding into or upwards extending out of an inner cavity of a lower pile shell is slidably connected into the lower pile shell, a lifting mechanism for driving the upper pile shell to move up and down is arranged in the lower pile shell, a controller is in signal connection with an infrared sensing device, and the controller is electrically connected with a light source plate and a loudspeaker. The lower pile shell is buried underground, when a person, a vehicle or other objects get close to the upper pile shell at night, the infrared sensing device detects a signal and feeds back the signal to the controller, the controller controls a motor to operate, the upper pile shell moves downwards to completely enter the inner cavity of the lower pile shell, therefore the upper pile shell is prevented from being collided, a safety warning pile is protected, and then the controller starts the light source plate and the loudspeaker, so that the sound-light alarm function is achieved, and passing personnel are reminded that electric power facilities exist nearby.

Owner:安徽正量科技有限公司

Plush knitwear post-finishing electric control cabinet

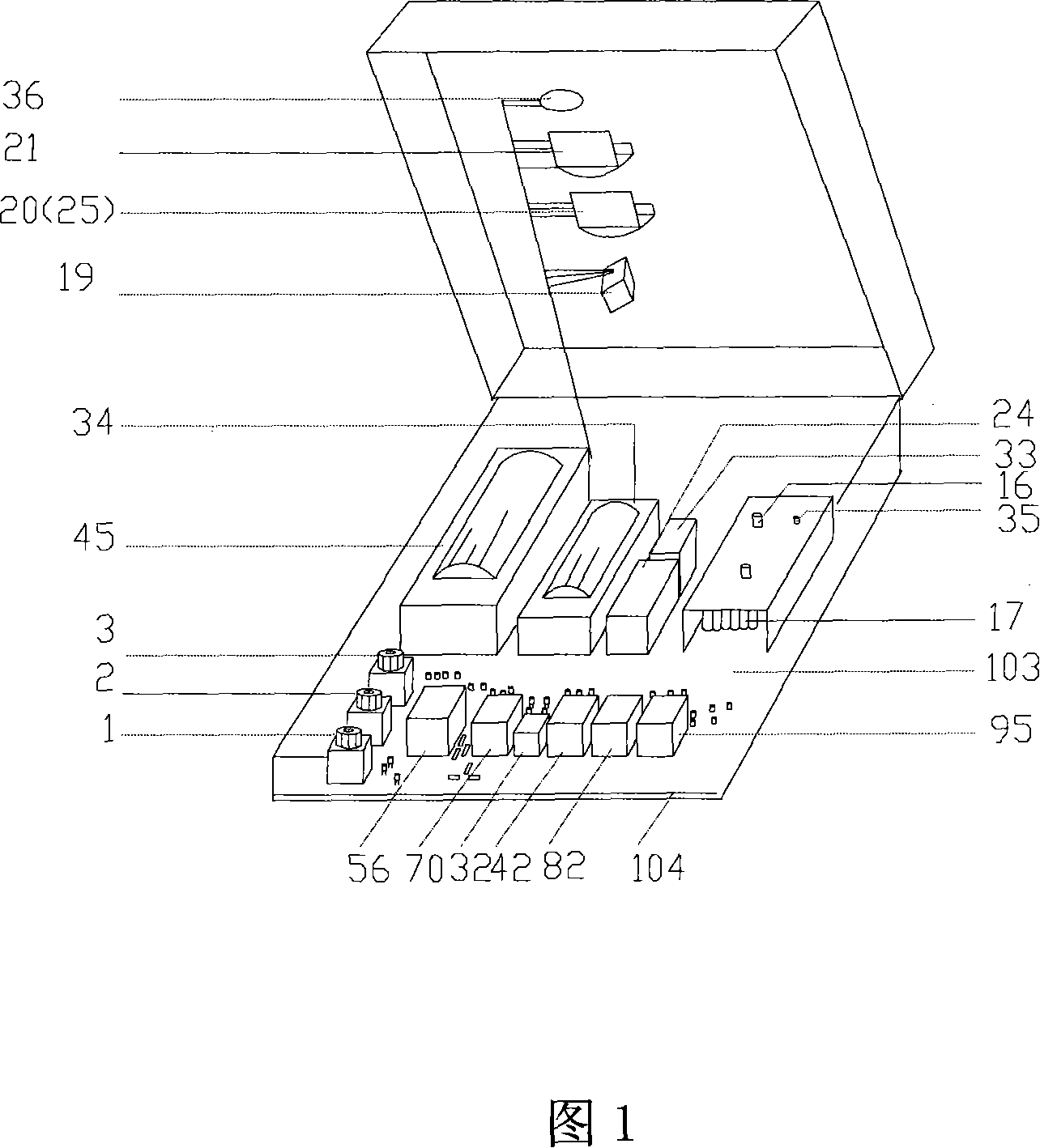

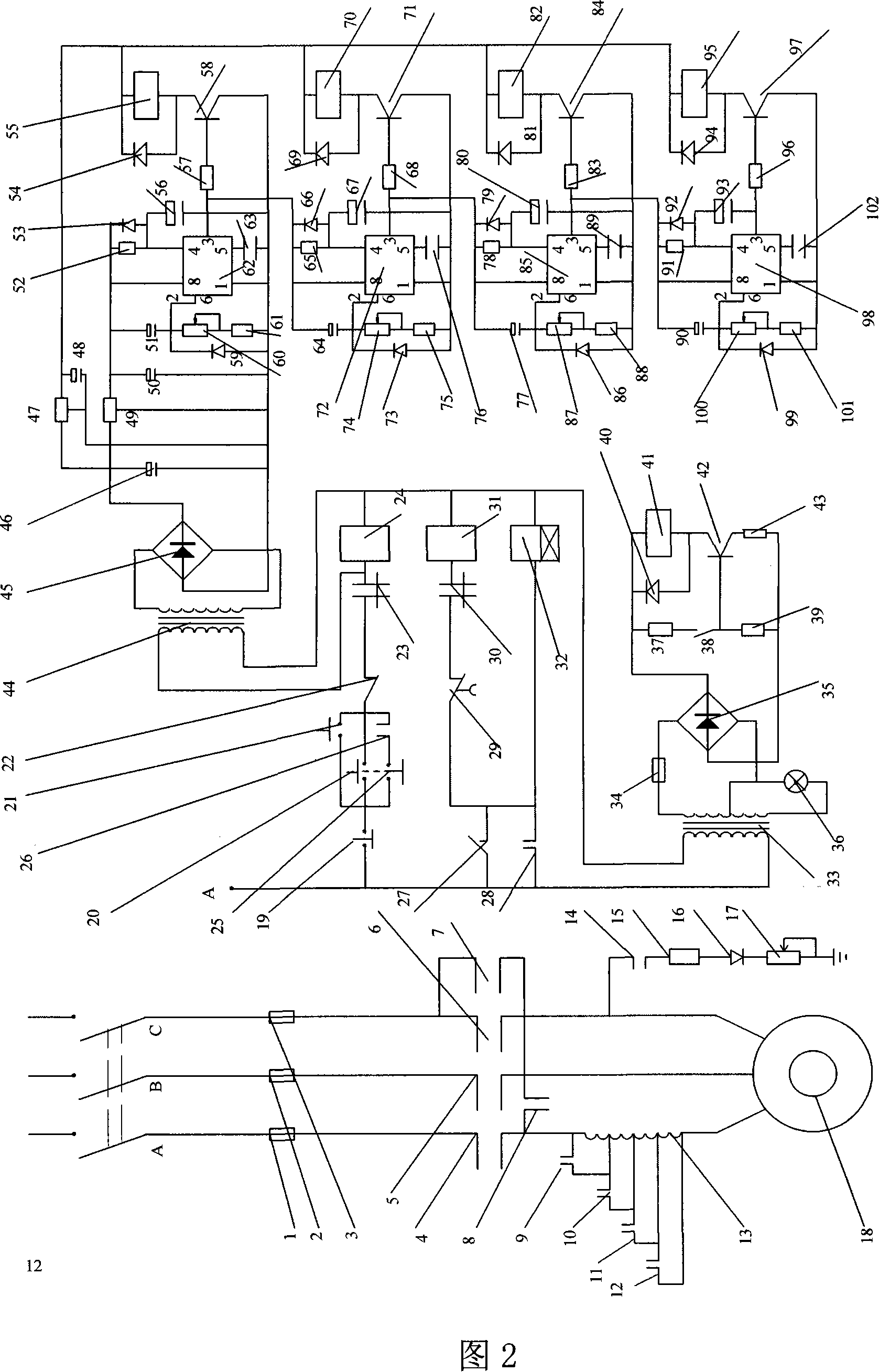

InactiveCN101083444ASimple structureEasy to produceMotor/generator/converter stoppersStarter detailsCapacitanceTransformer

The invention is a fleeced knit goods post-finishing electric control cabinet, for fleeced knit goods post-finishing set to protect electric motor and circuit, where it connects in series a reactor in the original actuating loop of the homemade fleeced knit goods post-finishing distribution cabinet; in the original circuit, removes a normally open button and adds transformer and rectifier, capacitor, and voltage stabilizing integrated block, as well as four timing circuits composed of several resistors, capacitors, diodes, triodes, 555 time base circuit, and so on. And it has multiples functions of startup, jogging, soft starting, artificial stopping slowly braking, auto stopping with failure, etc, and advantages of being simple to operate, low manufacturing cost, protecting electric motor, etc.

Owner:JIANGSU JUNFENG TEXTILE MACHINERY

Anti-collision device of automatic ultrasonic flaw detection system

InactiveCN101852777BFrom impactMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringMovement system

The invention discloses an anti-collision device of an automatic ultrasonic flaw detection system. An elastic element is sleeved outside a probe, and a protection cover is sleeved outside the elastic element. The upper end of the protection cover is connected with one end of a first connecting rod through a first hinge. The middle part of the first connecting rod is connected with one end of a mounting bracket through a second hinge. The other end of the first connecting rod is connected with one end of a second connecting rod through a third hinge. The other end of the second connecting rod is connected with one end of an inverted L-shaped connecting rod through a fourth hinge. The inverted L-shaped connecting rod is sleeved on the middle part of the mounting bracket, and the upper end face of the inverted L-shaped connecting rod is suspended at the inner side face of the mounting bracket through a spring. The lower end face of the inverted L-shaped connecting rod is connected with amicro-switch contact fixed in a fixed mount. When a foreign body hits the protection cover, the protection cover drives the first connecting rod to rotate around the second hinge so as to drive the second connecting rod to deflect a certain angle and drive the third connecting rod to move downwards to touch the micro-switch, then the moving system is stopped automatically so as to stop the movement of the probe to avoid collision of the expensive probe.

Owner:ZHEJIANG UNIV

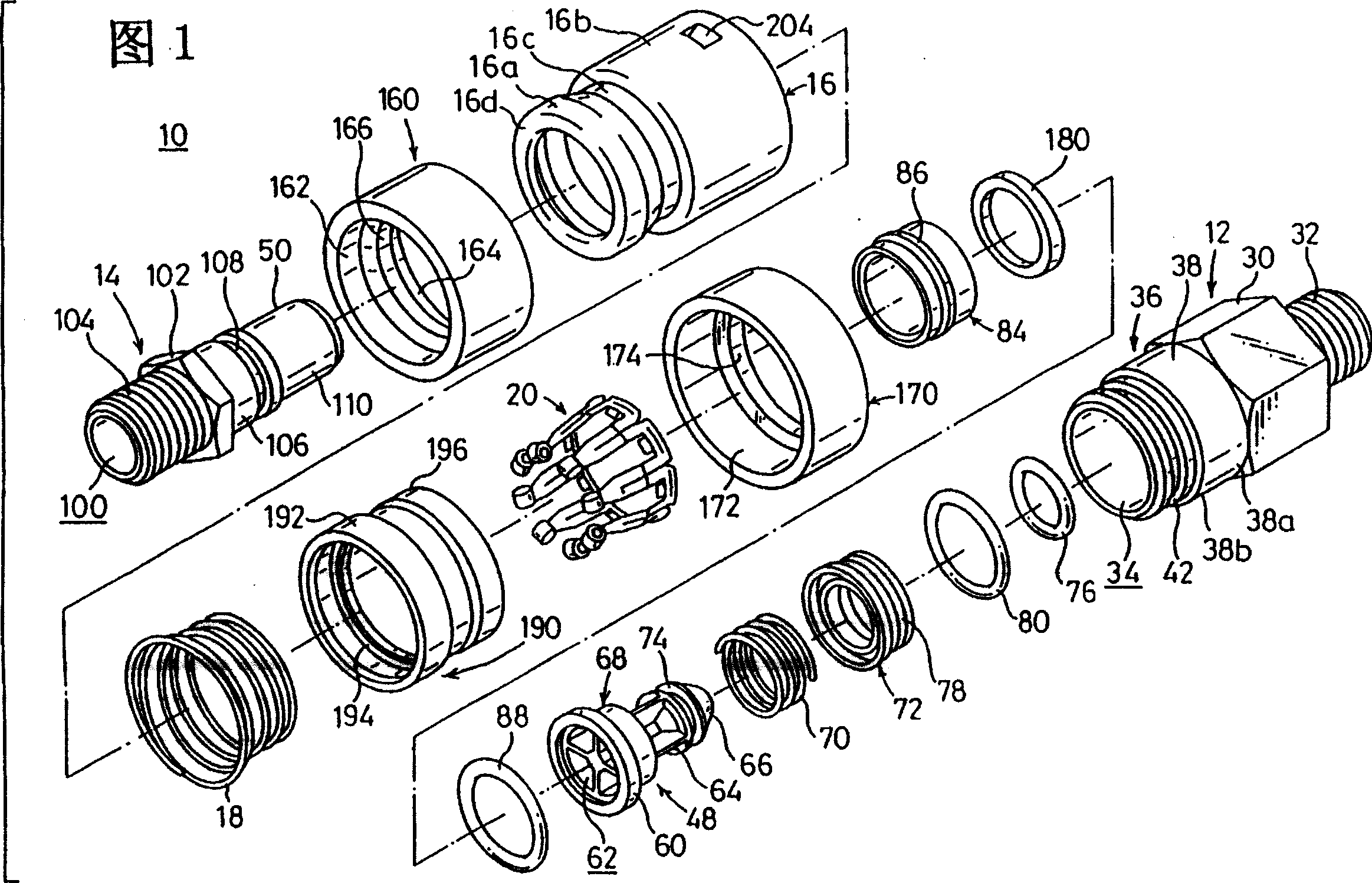

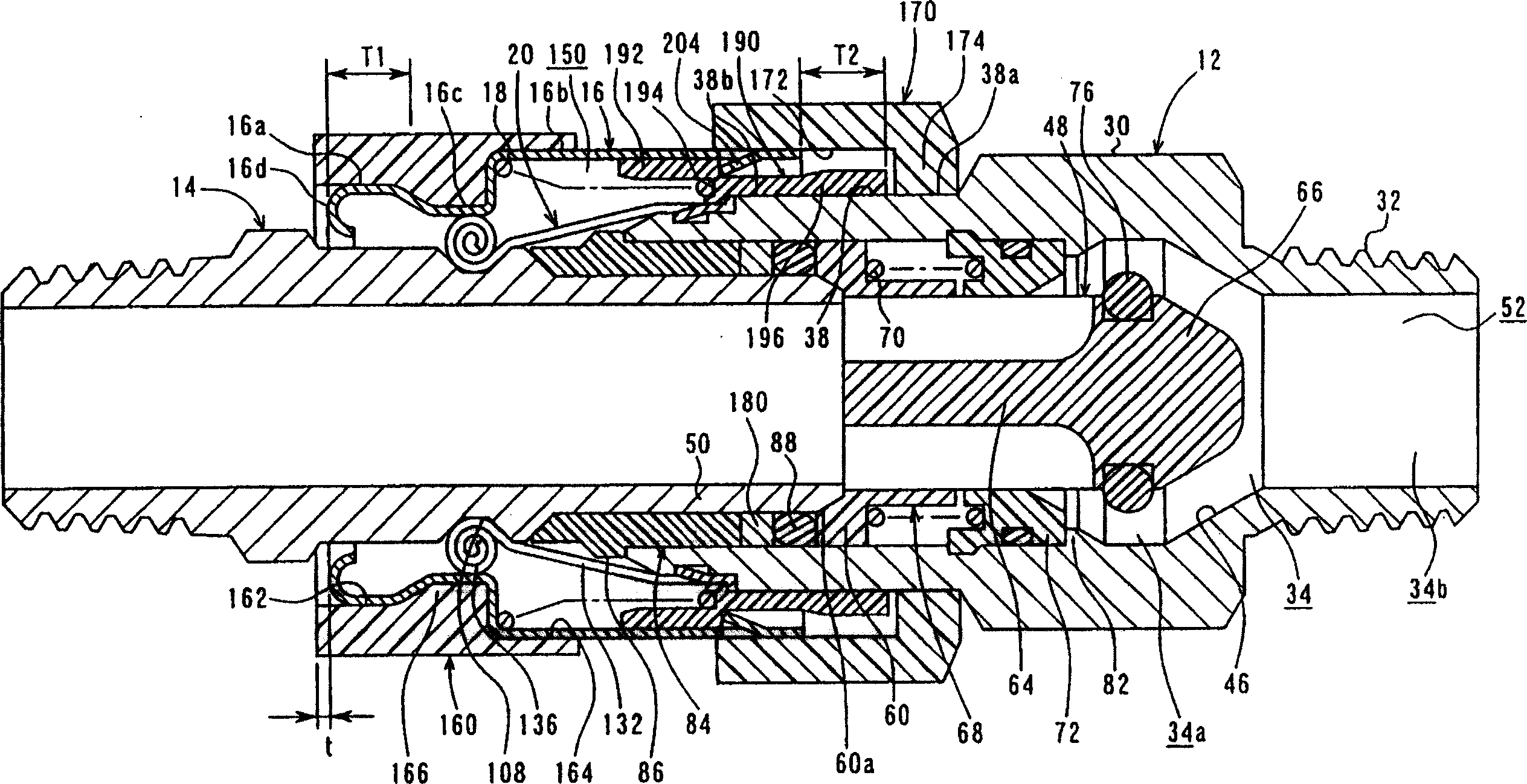

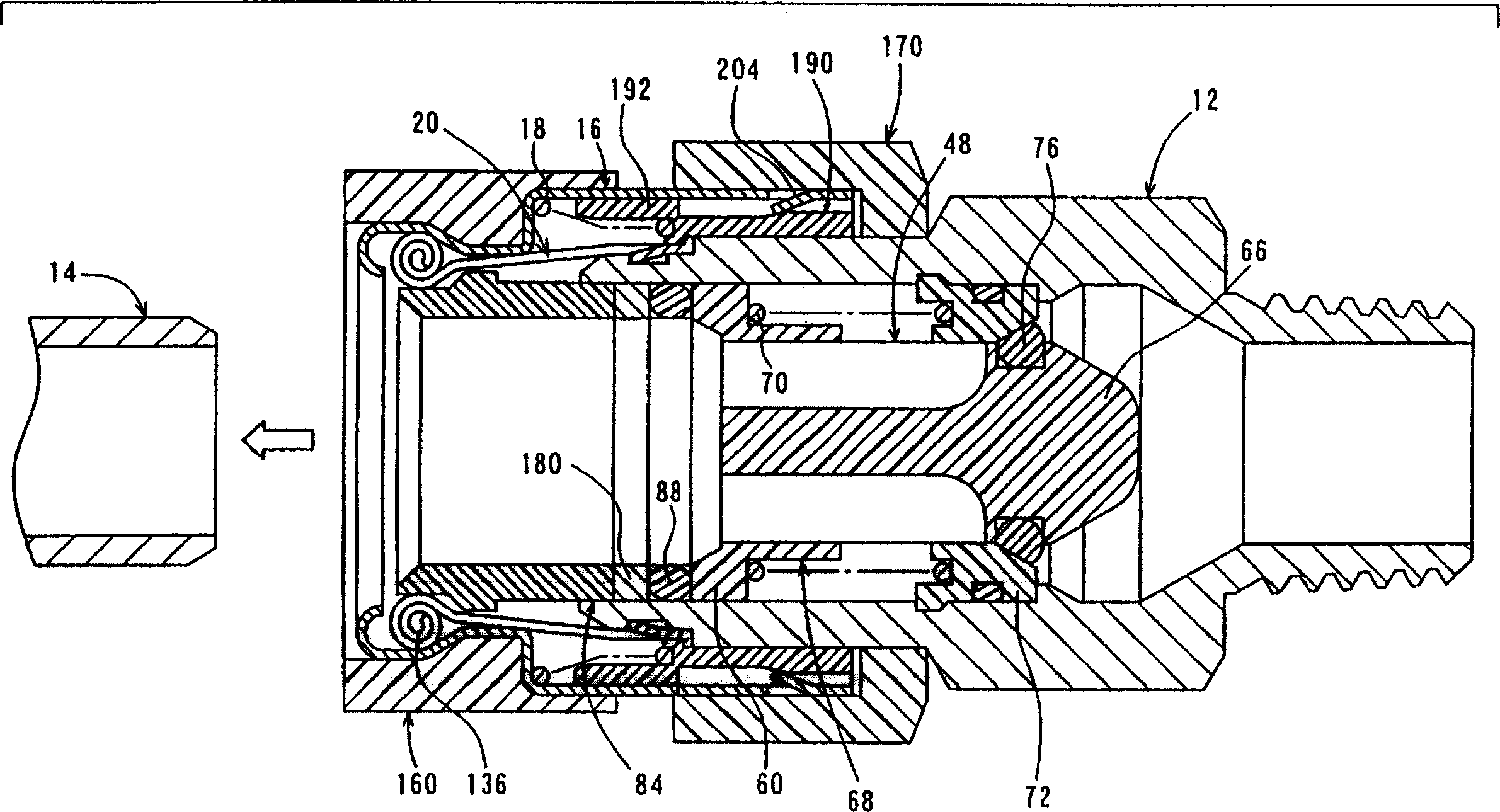

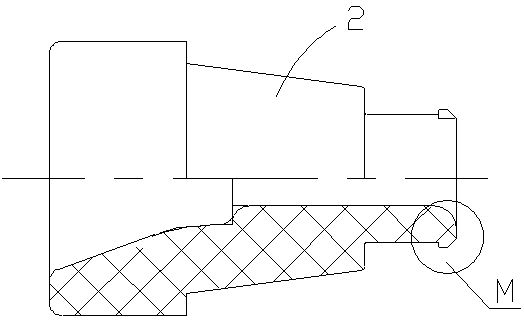

Pipe joint

InactiveCN1231693CFrom impactJoints with fluid cut-off meansCouplingsEngineeringBiomedical engineering

Owner:SMC CORP

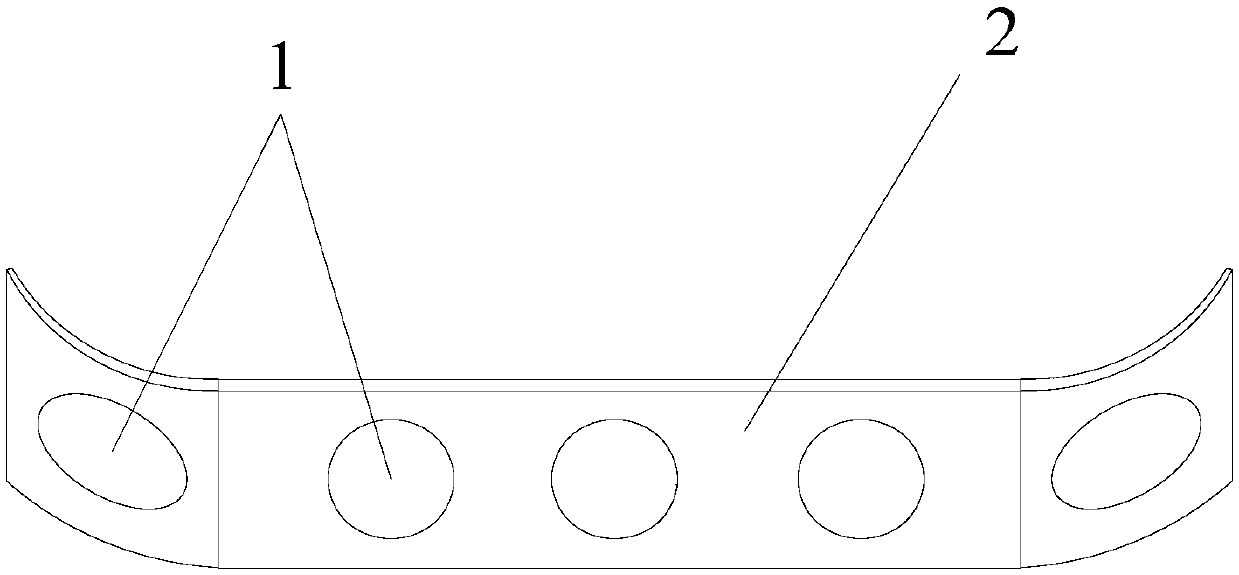

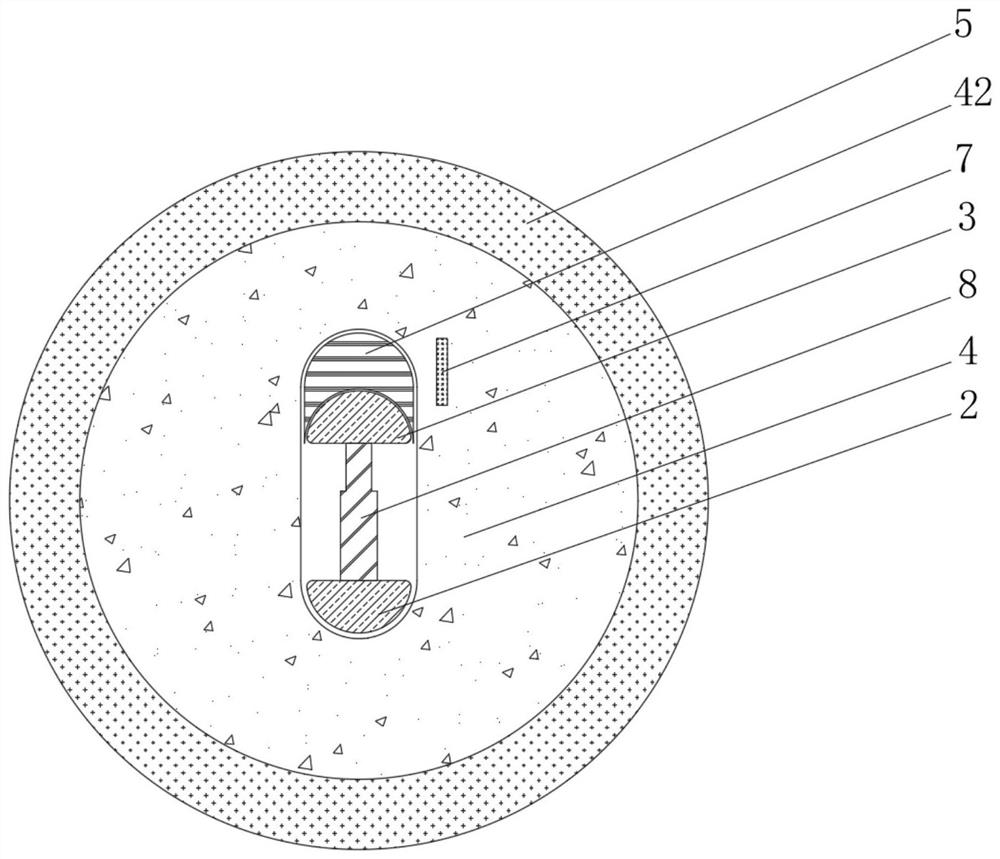

Anti-collision protector for pile body

InactiveCN106544971AExtended service lifeImprove toughnessClimate change adaptationShipping equipmentFiberEngineering

The invention discloses an anti-collision protector for a pile body. The anti-collision protector comprises a protector body, wherein the protector body is annularly arranged outside the pile body and is a steel wire mesh rubber concrete protector body or fiber mesh rubber concrete protector body which is made by using a fine steel wire mesh or a fiber mesh in rubber concrete; and the rubber concrete is made by doping concrete with short fibers and rubber particles. The anti-collision protector is simple in structure and can well protect the pile body.

Owner:WUHAN UNIV OF TECH

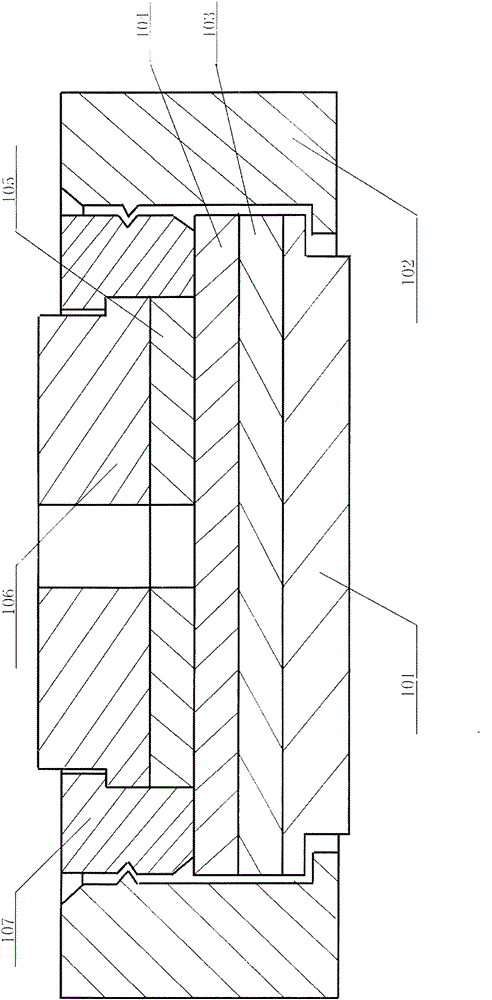

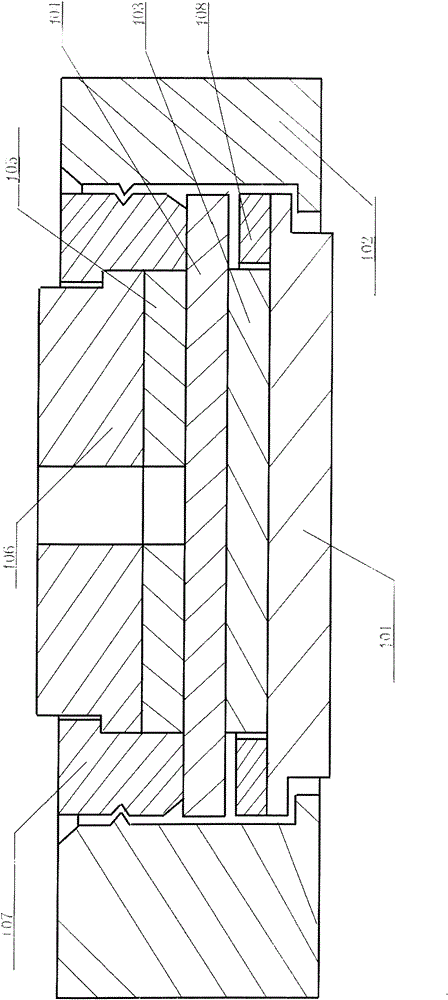

Combined type high-power semiconductor chip

ActiveCN102214642BFrom impactReduce thermal stressSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipCopper

The invention provides a combined type high-power semiconductor chip and belongs to the technical field of power electronic semiconductor devices. The combined type high-power semiconductor chip comprises a package body, a chip, molybdenum pieces and copper pieces, wherein the package body comprises an inner abnormally-shaped annular ring and an outer abnormally-shaped annular ring; an inward protruded clamping ring is arranged on the inner wall of the upper part of the outer abnormally-shaped annular ring (102); an inward protruded limiting block is arranged at the bottom of the outer abnormally-shaped annular ring (102); a groove which is combined with the clamping ring on the inner wall of the outer abnormally-shaped annular ring in a matched way is arranged on the outer edge of the inner abnormally-shaped annular ring (107); an inward protruded limiting block is arranged at the upper end of the inner abnormally-shaped annular ring (107); a lower copper piece (101), a lower molybdenum piece (103), the chip (104) and the inner abnormally-shaped annular ring are arranged in the outer abnormally-shaped annular ring; and an upper molybdenum piece (105) and an upper copper piece (106) are arranged in the inner abnormally-shaped annular ring. By the combined type high-power semiconductor chip, the chip, the molybdenum pieces and the copper pieces can be compressed with one another according to pressure of an outer clamping device, and aims of high product yield, low thermal stress, improvement on thermal cycle frequency, low cost, and convenience and quickness of assembly arefulfilled.

Owner:ANHUI PROVINCE QIMEN COUNTY HUANGSHAN ELECTRIC APPLIANCE

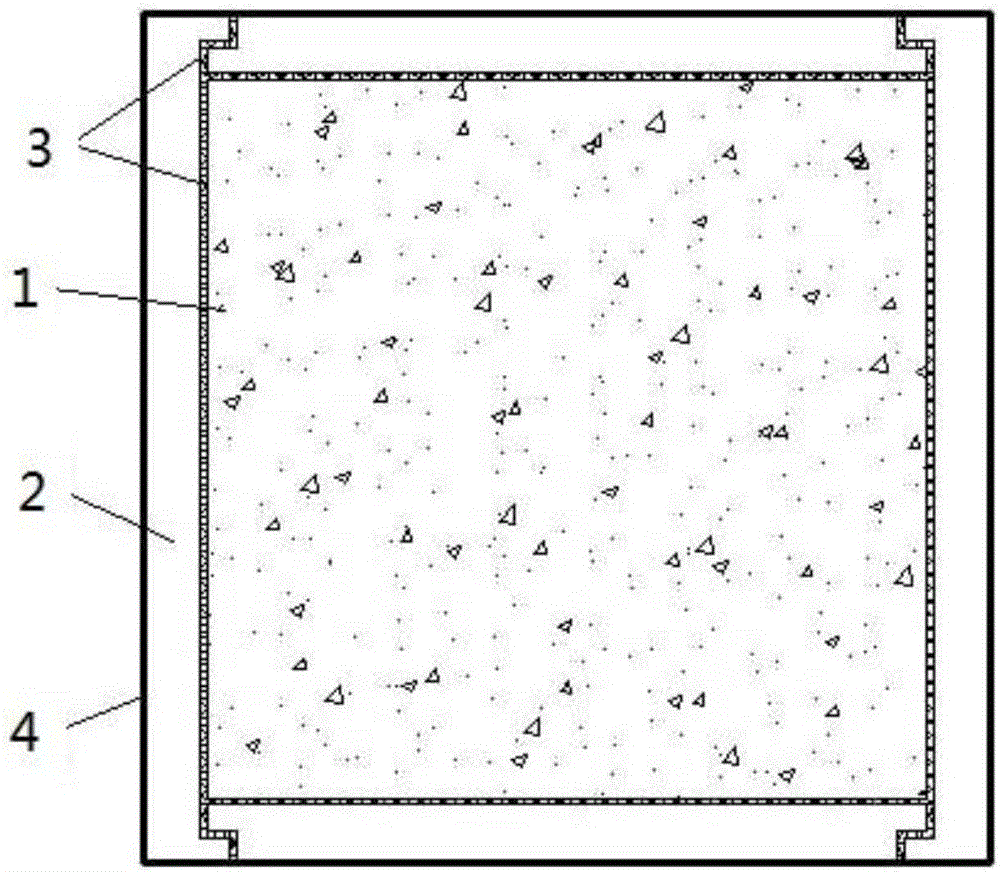

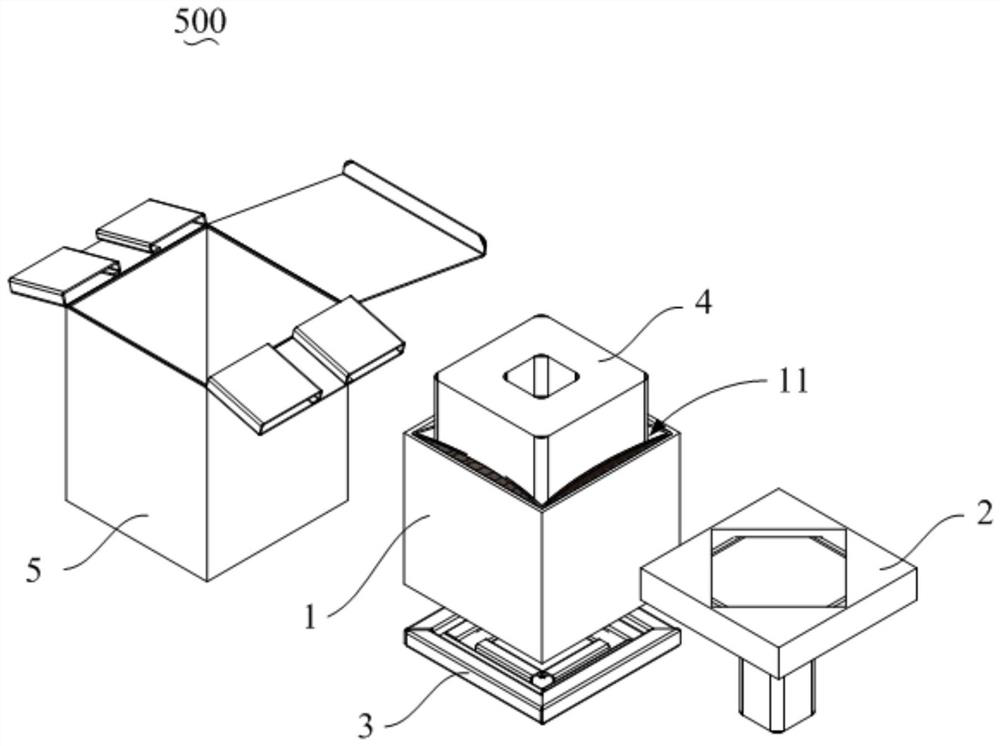

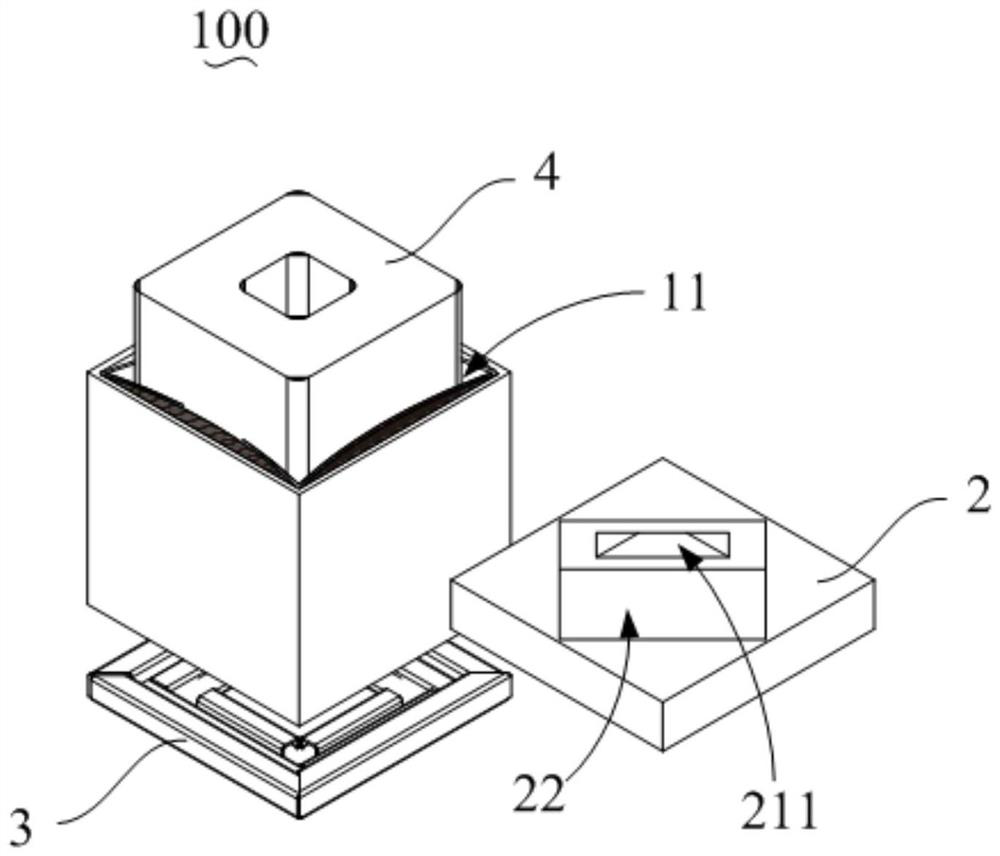

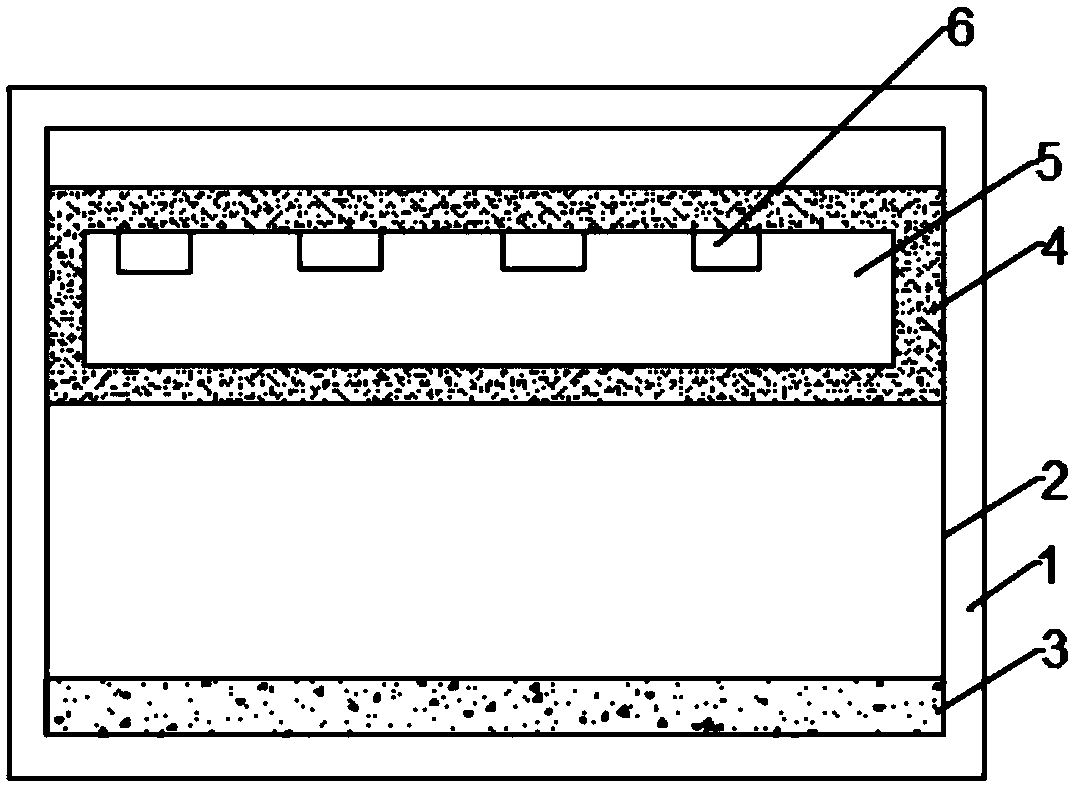

Buffer structure and packaging structure

PendingCN114524155AImplement packagingAvoid shaking damagePackage recyclingContainers to prevent mechanical damageUncrewed vehicleStructural engineering

The invention relates to the technical field of packaging, and particularly discloses a buffering structure and a packaging structure.The buffering structure comprises a buffering body, an upper buffering piece and a lower buffering piece, a buffering cavity is formed in the side, facing a mounting cavity, of the buffering body, and a containing space used for containing a product is defined by the buffering cavity; therefore, the product in the accommodating space can be limited and propped against the cavity wall of the buffer cavity. The unmanned aerial vehicle is placed in the containing space, the cavity wall of the buffering cavity abuts against the unmanned aerial vehicle in a limiting mode so that the position of the unmanned aerial vehicle can be fixed, the opening of the containing space is blocked through the upper buffering part and the lower buffering part so that the unmanned aerial vehicle can be limited in the containing space, the outer side of the buffering structure is sleeved with the packaging structure, and packaging of the unmanned aerial vehicle is achieved. Through the arrangement of the buffer cavity, the unmanned aerial vehicle can be limited and fixed in the containing space, the unmanned aerial vehicle is prevented from shaking and being damaged in the containing space, and in the transportation process, the buffer cavity can absorb impact force and protect the unmanned aerial vehicle from being impacted.

Owner:GEER TECH CO LTD

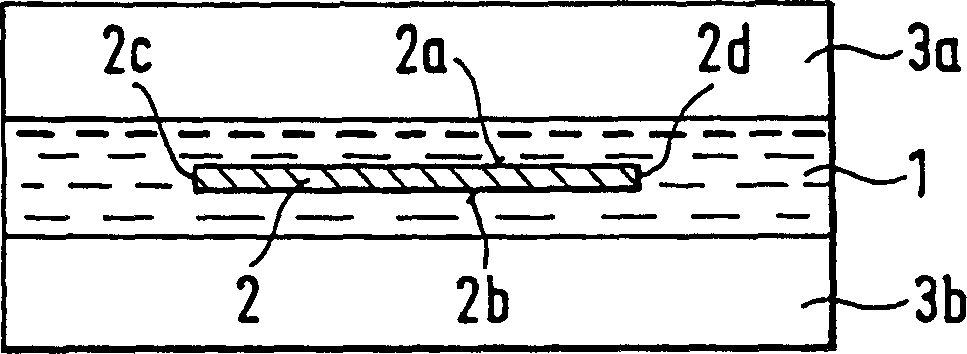

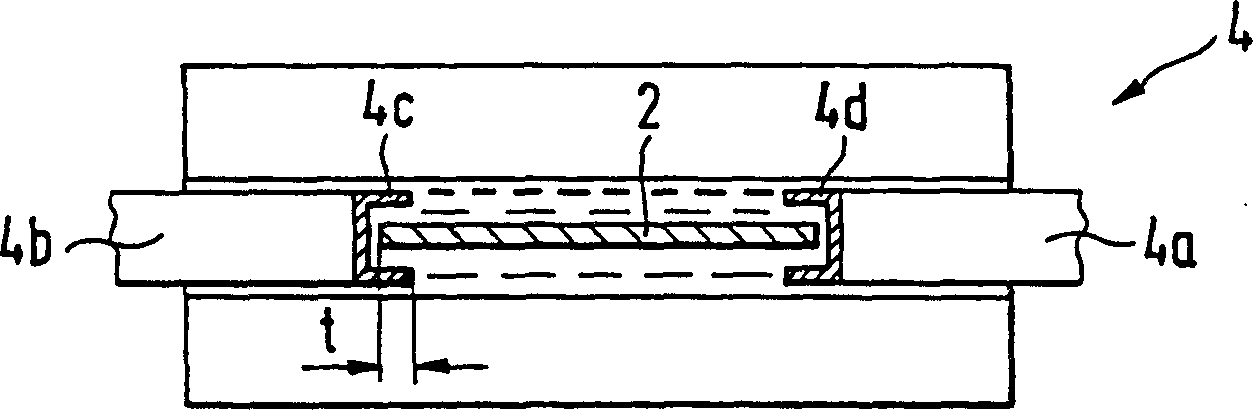

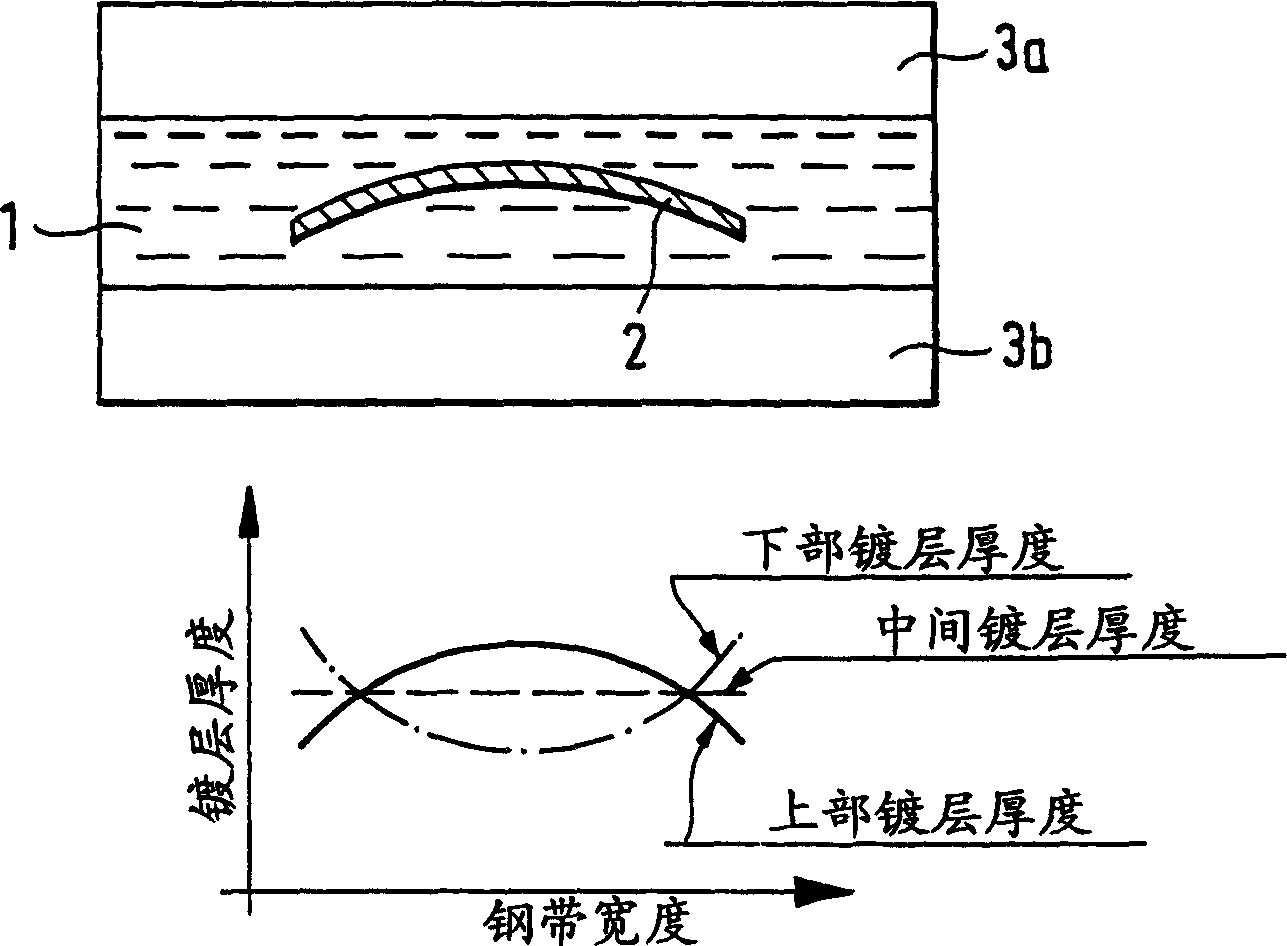

Device for electroplating steel band coating

The invention provide an apparatus for electrogalvanic coating which surely prevents the edge excessly depositing of the separate metal, simultaneously eliminates the difficulties of the apparatus to be used for edge masks. The solution with the above project is that: in the said type apparatus, the respective anodes are divided to several anode stripes in parallel with the moving direction of the band plate and these anode stripes are insulated from each other. A current is passed discretely through each of the respective anode stripes.

Owner:SMS SCHLOEMANN SIEMAG AG

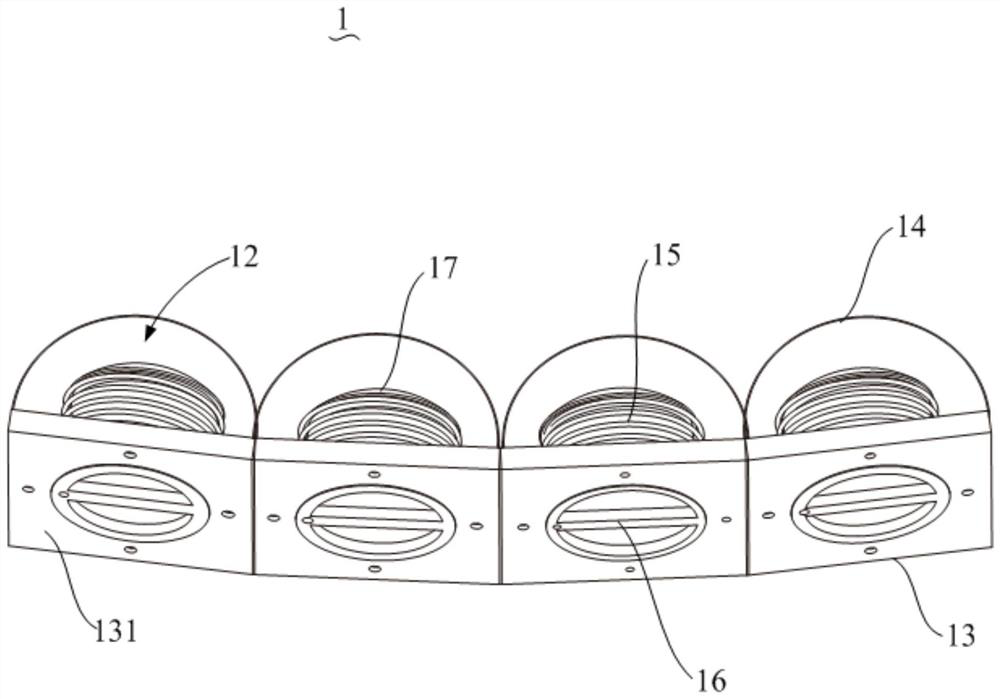

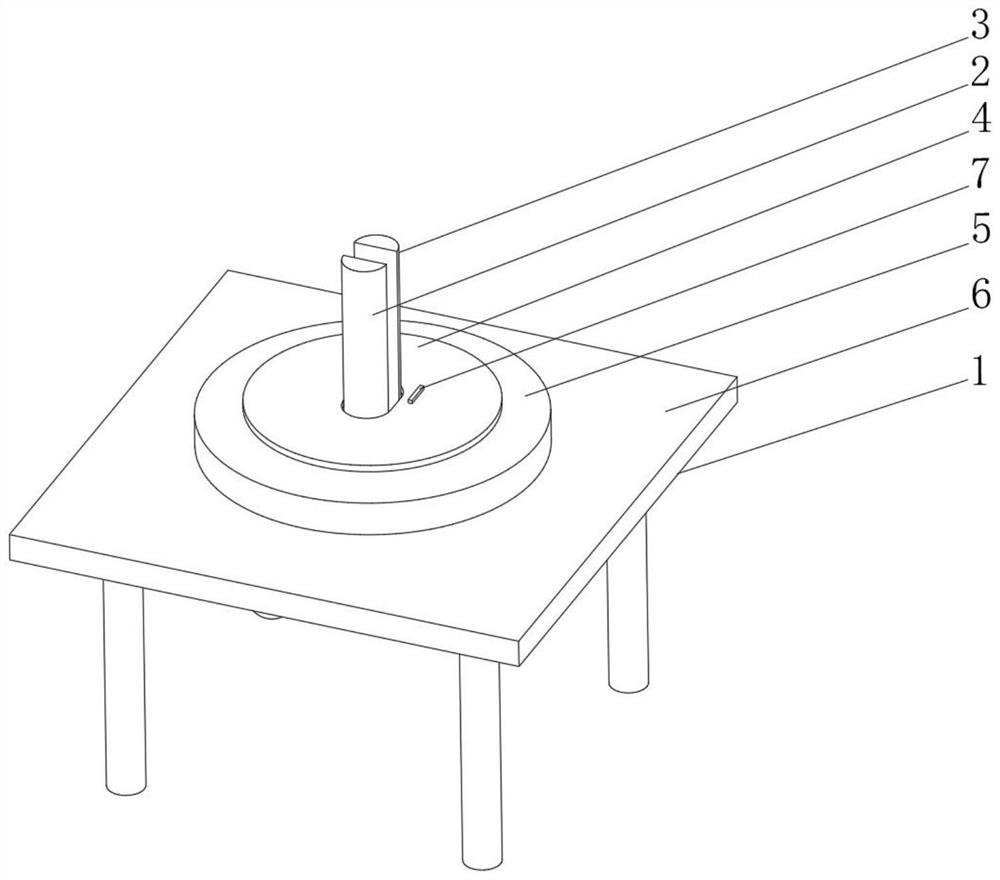

Machining pipe winding device

PendingCN112620518AGuaranteed limit effectGuaranteed stabilityNon-rotating vibration suppressionHeat exchange apparatusEngineeringMachine

The invention discloses a machining pipe winding device, which comprises a machining pipe winding device body composed of a base fixed wheel, a movable wheel, a protective disc, a rotating wheel disc and a base; the protective disc comprises a carrying disc, an anti-pinch mechanism is slidably connected to the interior of the carrying disc, and a limiting clamp is fixedly connected to the top of the carrying disc; a hydraulic rod is fixedly connected to the inner side of the fixed wheel; the end, away from the fixed wheel, of the hydraulic rod extends into the movable wheel and is fixedly connected with the movable wheel; the bottom of the rotating wheel disc is fixedly connected with the top of the protection disc; and the bottom of the movable wheel extends into the rotating wheel disc and is in sliding connection with the rotating wheel disc. The invention relates to the technical field of machining. By means of the machining pipe winding device, the problems that a manual tooling is low in winding efficiency and prone to rebounding, or forming can be achieved through an expensive steel pipe winding special machine, but the cost is high and the universality is poor are solved.

Owner:张海军

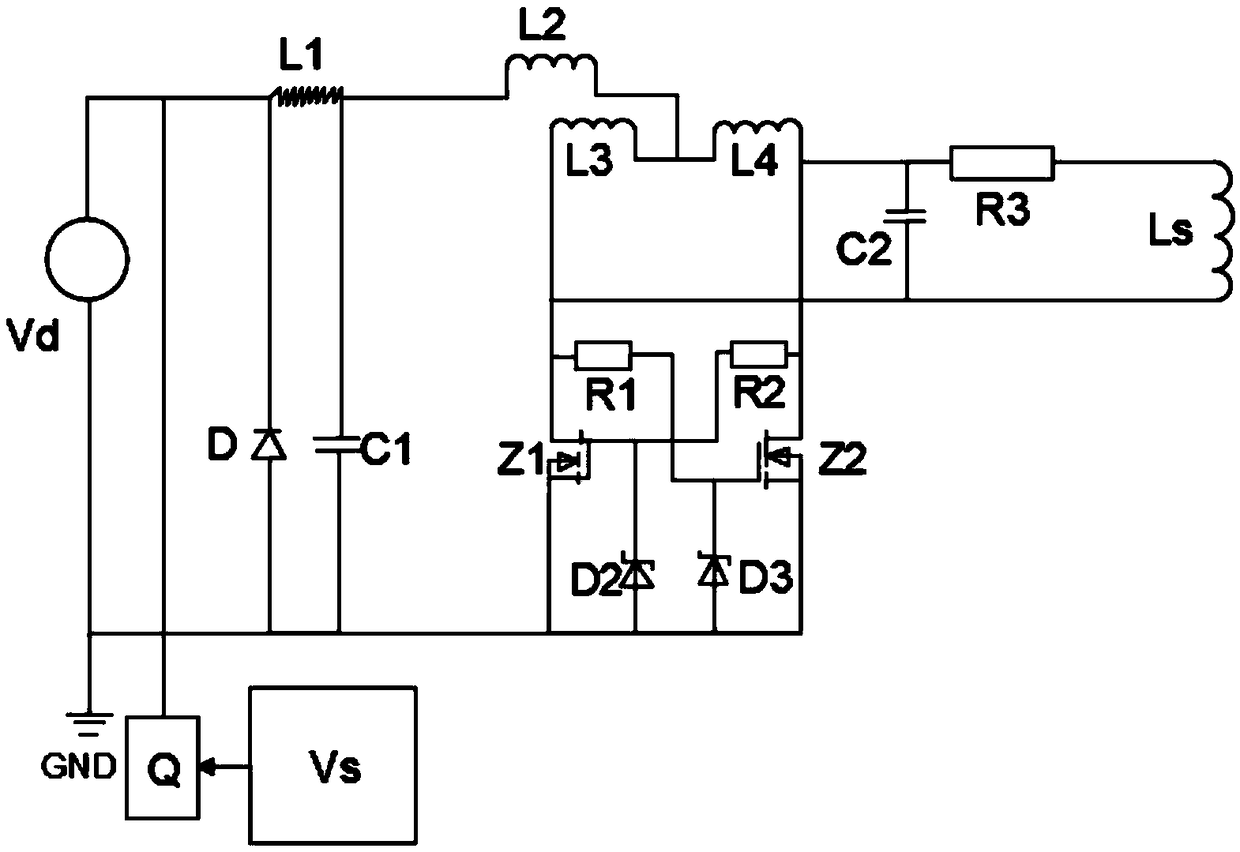

Cold accumulation heat preservation box temperature control equipment utilizing eddy current technology

ActiveCN108750407AFree from stressFrom impactDomestic cooling apparatusLighting and heating apparatusBlocking layerGetter

The invention discloses cold accumulation heat preservation box temperature control equipment utilizing an eddy current technology. The cold accumulation heat preservation box temperature control equipment comprises a box body and an eddy current temperature control circuit board, the interior of the box body is fixedly provided with a vacuum heat insulation plate, a gas blocking layer is fixedlyarranged on the inner wall of the vacuum heat insulation plate, a core material is arranged inside the gas blocking layer, the inner wall of the core material is fixedly provided with a plurality of gas getters, the eddy current temperature control circuit board is welded on the front surface of the vacuum heat insulation plate, and a current source connecting port is integrally formed in the surface of the eddy current temperature control circuit board. According to the cold accumulation heat preservation box temperature control equipment utilizing the eddy current technology, the circuit isa self-excited oscillation type converter so as to be used to generate high-frequency current and then to generate a high-frequency alternating magnetic field; and the temperature control circuit is acompletely autonomous system which does not need external signals, and therefore, the system cost can be reduced to a great extent, meanwhile, the requirement for a phase-splitting converter is alsoreduced, moreover, the weight and the size of a direct-current inductor can be reduced, and the practicability of a cold accumulation heat preservation box is improved.

Owner:芜湖英特杰智能科技有限公司

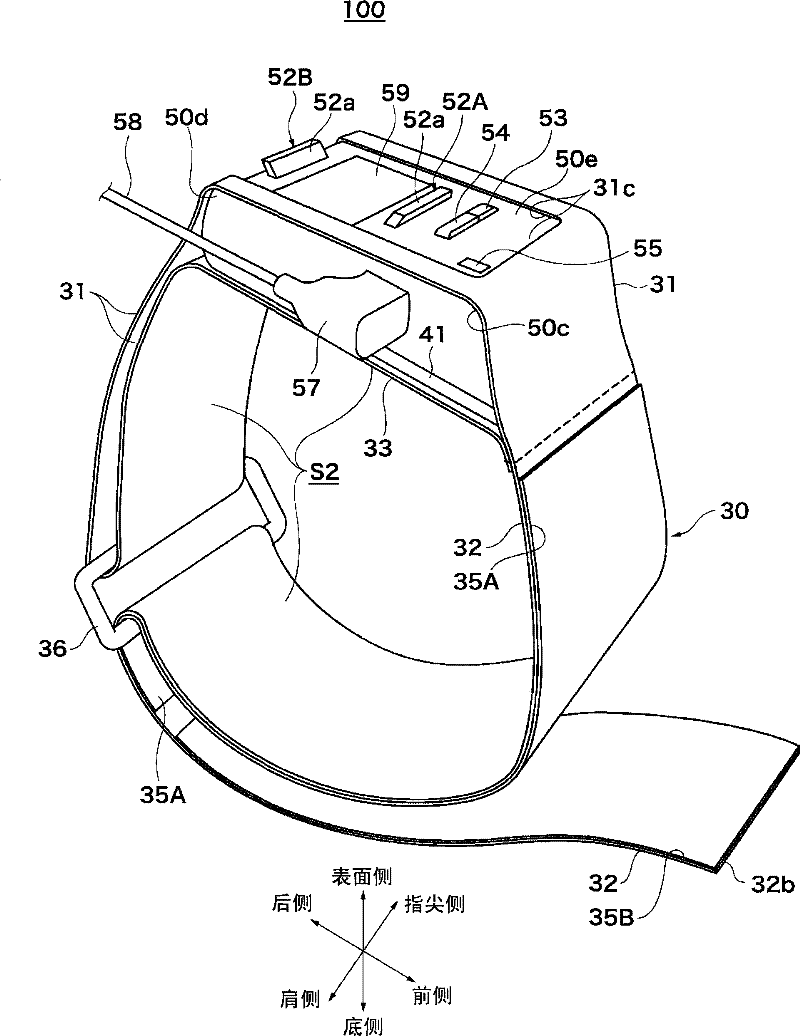

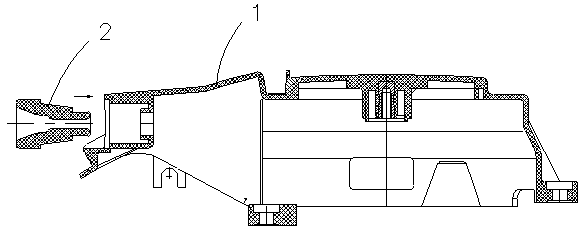

Portable electronic device

InactiveCN101272413BFrom impactImprove Tilt AccuracyCasings/cabinets/drawers detailsTelephone set constructionsStructural engineeringHorizontal orientation

This invention provides a portable electronic device, which can improve inclined precision of base plate and positional precision on horizontal direction under the condition of having no damage to appearance and preventing the base plate from bumping. Elastic frame body (78) is integrally formed into a quadrilateral frame structure, inside of which holds a circumferential part (74a) of the base plate (74) by embedding. When the surface side shell (70) and inner side shell (90) are embedded and screw (89) is screwed to each protruding table (86), inner side face of the elastic frame body (78) is pressed on protruding parts (93), (94) and front end of side rid (91) of the inner side shell (90). Conical surfaces (78c1-78c4) of the elastic frame body (78) are firmly resisted against conical surfaces (72d1)-(72d4) of corresponding surface side shell (70). Therefore, the base plate (74) is held on device main body (50) by the elastic frame body (78).

Owner:YAMAHA CORP

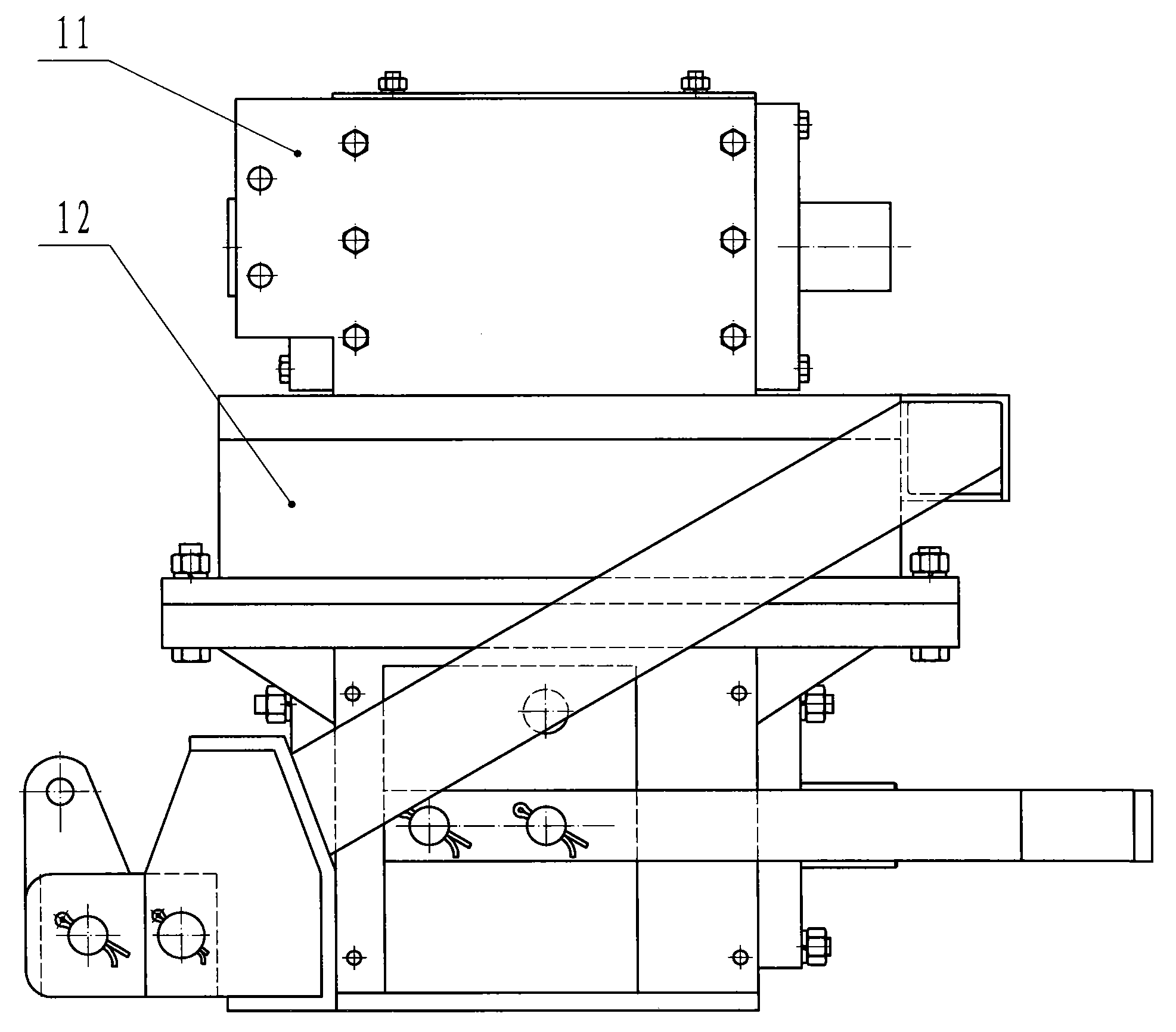

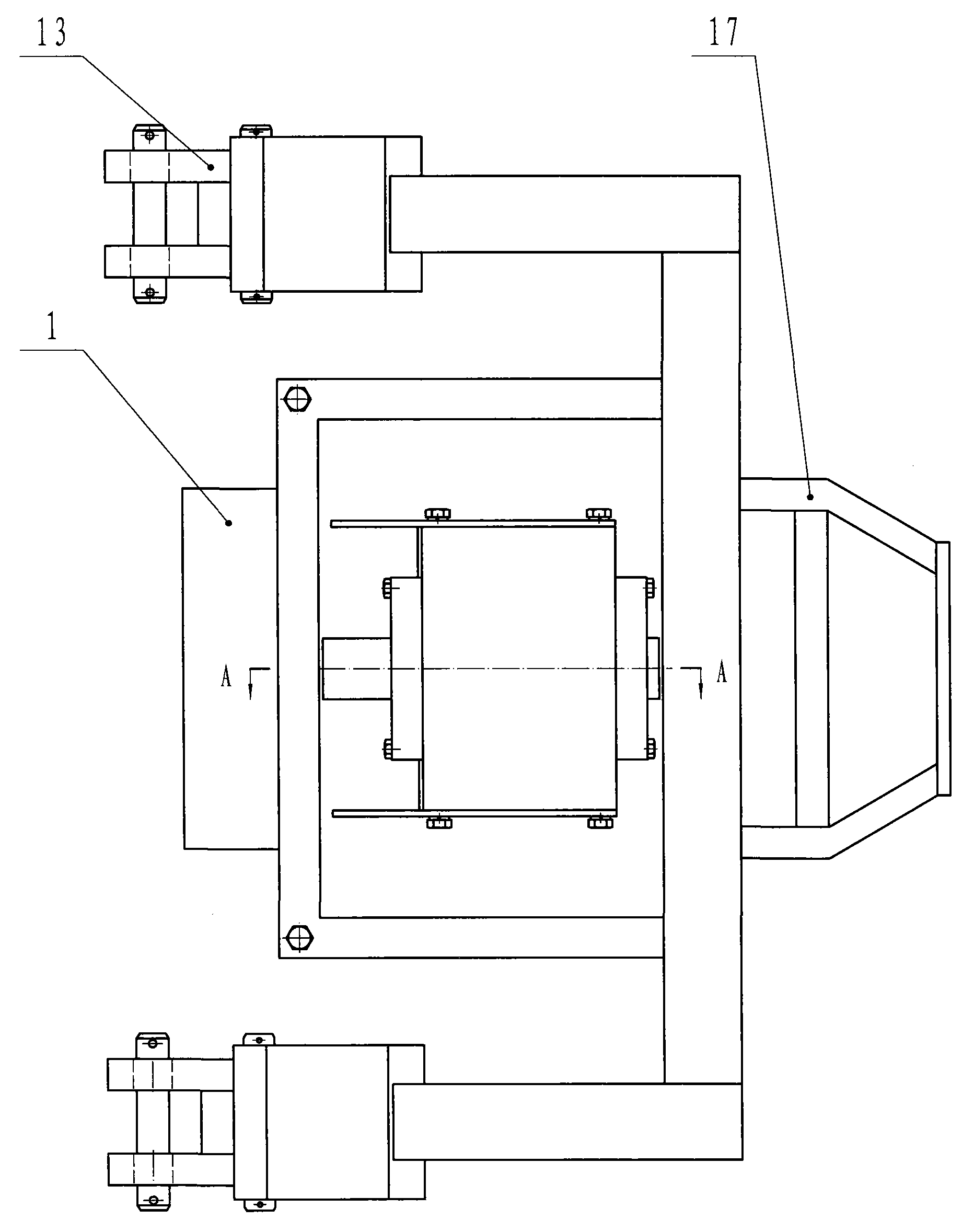

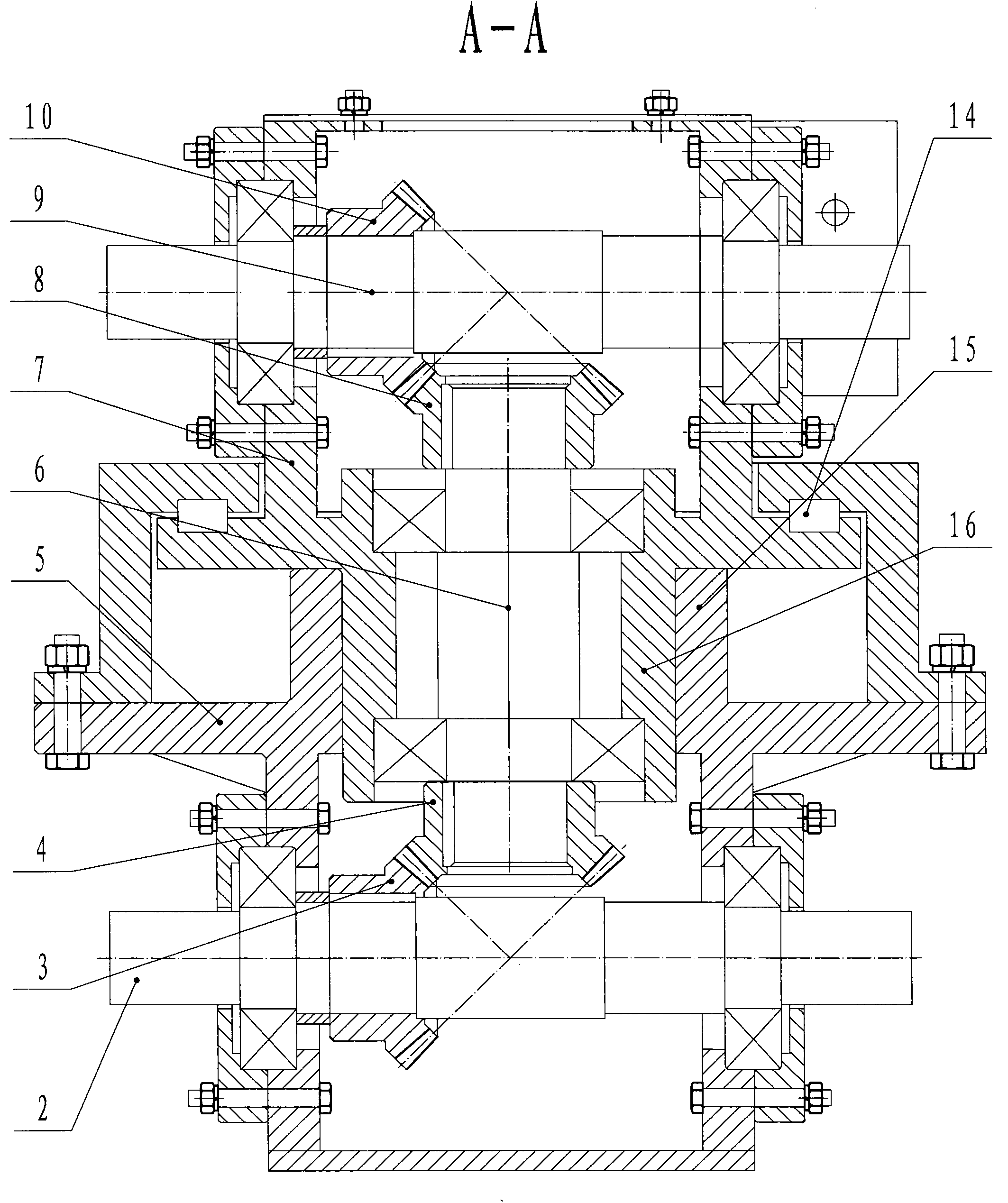

Vertical shaft rotary traction mechanism of forage harvesting and flattening machine

InactiveCN104074924BReduce frictionFrom impactHarvestersToothed gearingsElectric power transmissionTransmitted power

The invention provides a vertical shaft rotation type drawing mechanism for a forage grass cutting flatting mill. The vertical shaft rotation type drawing mechanism comprises a first horizontal shaft protecting cover, a first horizontal shaft, a bevel gear, a power input box, a rotation box, a vertical shaft, a second horizontal shaft, a connecting plate, a limiting box, a connecting frame, a cylindrical roller and a supporting frame. A tractor transmits power to the first horizontal shaft, the first horizontal shaft transmits power to the vertical shaft, the vertical shaft transmits power to the second horizontal shaft, the second horizontal shaft transmits power to the forage grass cutting flatting mill, and power transmission is finished. When the tractor makes a turn, a power transmission system works normally, the power input box and the limiting box make a turn together with the tractor, the power input box rotates around the vertical shaft with the axis of a round sleeve as the center, and the forage grass cutting flatting mill can be immobile at the original position. When the tractor continues to run after making a turn, the rotation box is subject to forward traction and pulls the forage grass cutting flatting mill to work. When the vertical shaft rotation type drawing mechanism is in work, the supporting frame is put away and locked at 0 degree; after the work is finished, the supporting frame is placed down to be locked at 90 degrees, and the forage grass cutting flatting mill is supported.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

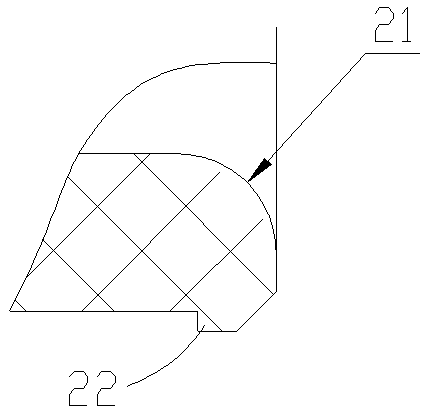

Anti-collision device for probe of ultrasonic inspection system

InactiveCN101871915BFrom impactMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringMovement system

The invention discloses an anti-collision device for a probe of an ultrasonic inspection system. An elastic element is sleeved outside the probe; a protective cover is sleeved outside the elastic element; the upper end of the protective cover is connected with one end of a first connecting rod through a hinge; the middle part of the first connecting rod is connected with a fixing bracket through a spherical part; the other end of the first connecting rod is connected with one end of a second spherical connecting rod through a hemispherical part; the other end of the second spherical connecting rod is connected with one end of a reverse L-shaped hemispherical connecting rod; the reverse L-shaped connecting rod is sleeved on the middle of the fixing bracket; meanwhile, the upper end face ofthe reverse L-shaped connecting rod is hung on the inner side face of the fixing bracket through a spring; and the lower end face of the reverse L-shaped connecting rod is connected with an inching switch contact arranged in the fixing bracket. When a foreign body knocks down the protective cover, the protective cover drives the first connecting rod to rotate around a second hinge so as to drive the second connecting rod to deflect for an angle and drive a third connecting rod to move downwards to touch the inching switch to automatically stop a movement system to stop the probe so as to protect the expensive probe from being knocked.

Owner:ZHEJIANG UNIV

Protective type exhaust pipe casing pipe with heat radiation function

InactiveCN104727916APrevent rust and corrosionGood ventilation and heat dissipationExhaust apparatusSilencing apparatusRadiationExhaust pipe

The invention discloses a protective type exhaust pipe casing pipe with a heat radiation function. The protective type exhaust pipe casing pipe with the heat radiation function comprises a casing pipe body, wherein the casing pipe body is connected with an exhaust pipe in a sleeving mode, the two ends of the casing pipe body are communicated, a plurality of protective convex blocks are arranged on the lower end pipe wall of the casing pipe body, vents are formed in the bottoms of the protective convex blocks, the protective convex blocks are arranged backwards aslant, and a rear end outlet of the casing pipe body is further provided with a purification net cover. In this way, the exhaust pipe can be effectively protected, the bottom of the exhaust pipe is prevented from being impacted, the exhaust pipe is prevented from being rusted and corroded, and the casing pipe body has a good ventilation and heat radiation effect.

Owner:王爱红

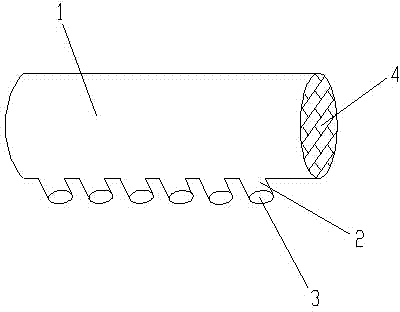

A wear-resistant sleeve for an outboard motor starting wheel and an assembly process method thereof

ActiveCN107792328BImprove wear resistanceHigh precisionPropulsion power plantsOutboard propulsion unitsCompression moldingInterference fit

The invention discloses a wear-resistant sleeve for a starting wheel of an outboard engine and an assembly process method thereof. The wear-resistant sleeve is characterized in that an insert sleeve body is sequentially provided with a plurality of sections with outer diameters from large to small, wherein a middle section is a cone; the outer diameter of the section with the minimum diameter in three sections is in interference fit with an bearing inner hole of a starting cover of the outboard engine; a plurality of lug bosses extending in a radial direction are arranged at the end of the section with the minimum diameter of the insert sleeve body; an arc chamfer is arranged at the end of the inner hole of the section with the minimum diameter of the insert sleeve body; and the insert sleeve body and the starting cover of the outboard engine are laminated into an integrated structure when the starting cover of the outboard engine is in a thermal expansion state. The insert sleeve bodyformed through compression molding by adopting bakelite powder has high wear resistance and high accuracy and is free from the influence of outward friction force when a nylon starting rope is pulledso as to avoid falling; the fluffing and breaking phenomena of the nylon starting rope are reduced, and the personal safety of a user is ensured; and the qualified rate of starting cover combinationproducts is greatly improved.

Owner:浙江沧龙动力机械有限公司

An aircraft seat with head cushioning and anti-collision function

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

joint airbag module

Disclosed is a unification airbag module. The unification airbag module includes a cushion to protect a front and a side of an occupant, a fixing member mounted on a ceiling of a vehicle and formed therein with a capacity such that the cushion is rolled and received in the cavity, and an inflator supplying inflation gas to the cushion. The cushion includes a front portion corresponding to a head and a chest of the occupant, and a side portion corresponding to both sides of the head and the chest of the occupant. A main chamber is formed on edges of the front and side portions, and a plurality of sub-chambers communicating with the main chamber are formed at the front portion and the side portion. The occupant is completely surrounded by the unification airbag module so that the occupant is protected from the front collision and the side collision.

Owner:AUTOLIV DEV AB

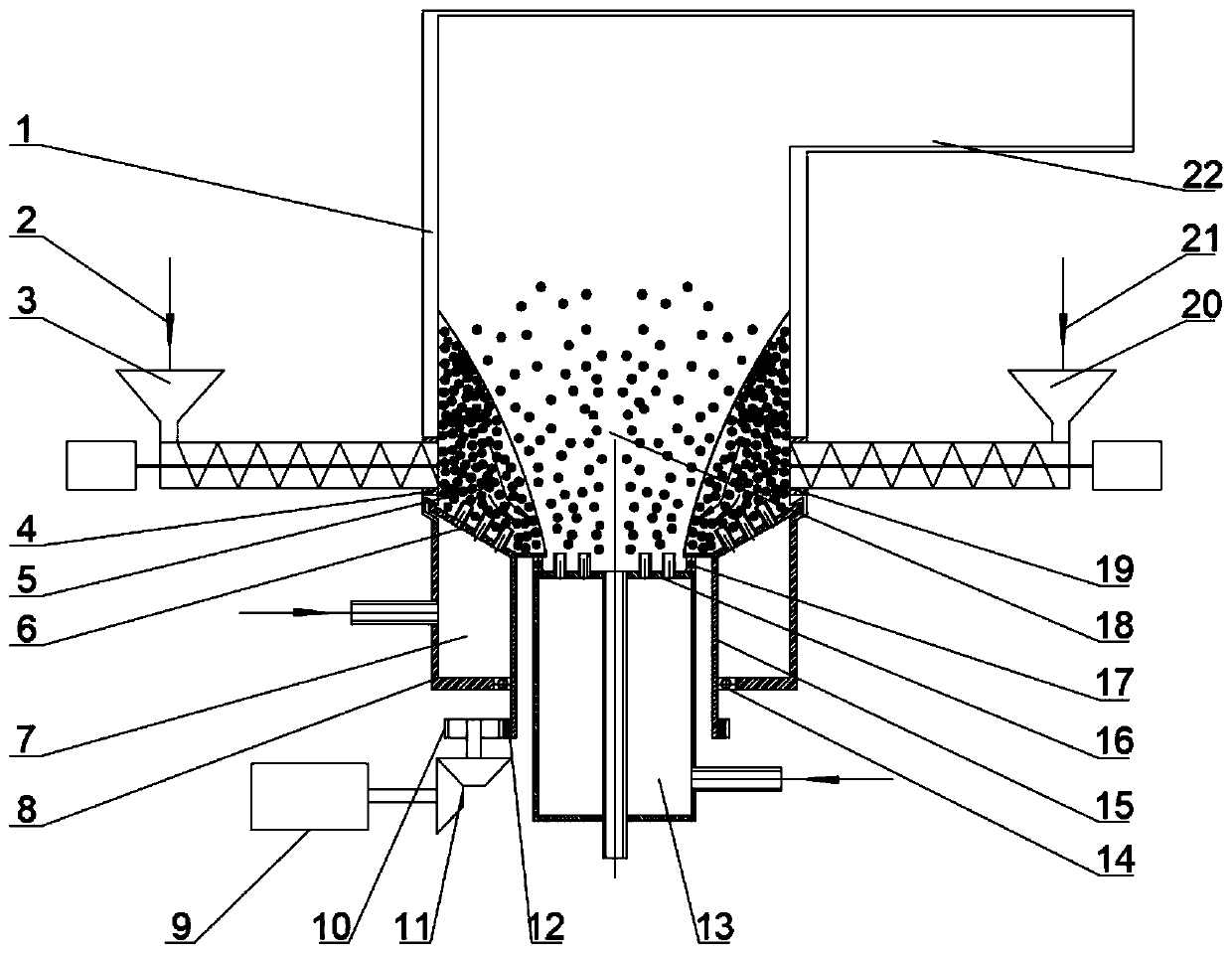

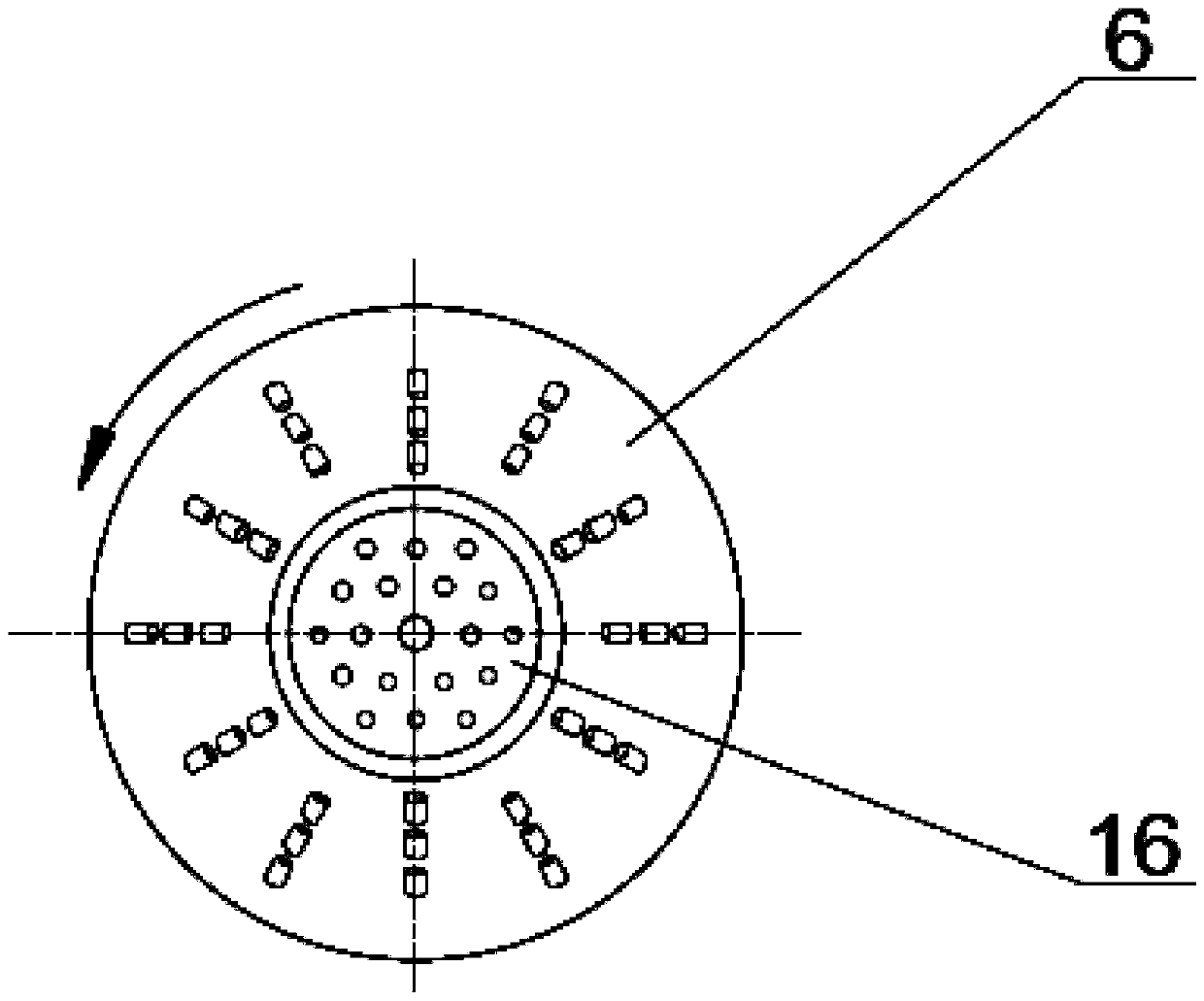

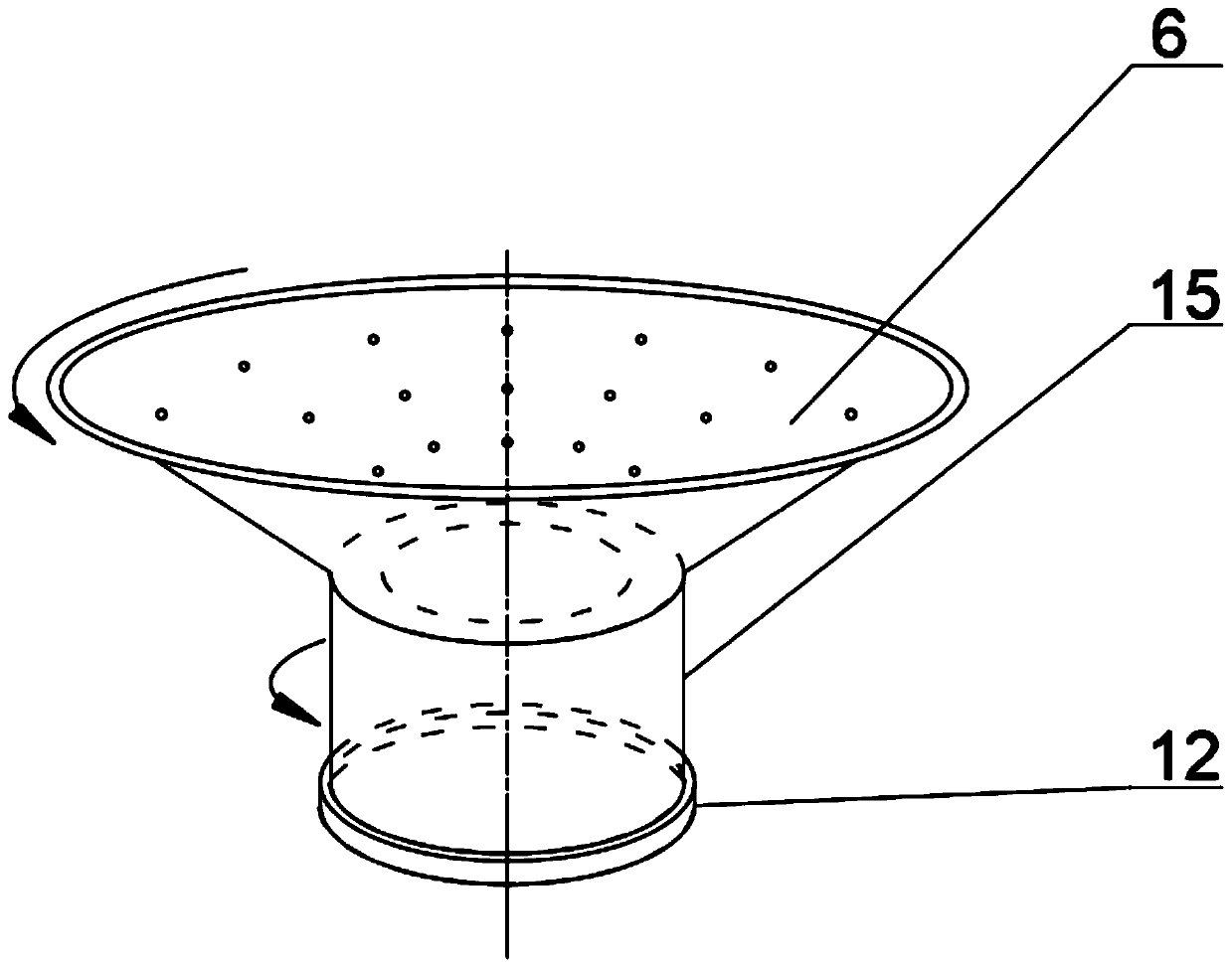

Fluidized bed combustion furnace and combustion method

ActiveCN111288438ASolve the problem of incomplete combustionReduce volumeFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringFluidized bed combustion

The invention discloses a fluidized bed combustion furnace and a combustion method. The fluidized bed combustion furnace comprise a fluidized combustion area and a rotary drying and layer combustion area; a material inlet of a fluidized bed is arranged on the rotary drying and layer combustion area, and the rotary drying and layer combustion area communicates with the fluidized combustion area; the rotary drying and layer combustion area is used for realizing rotary drying and layer combustion of materials; and the fluidized combustion area is used for carrying out fluidized combustion on thematerials which have passed through the rotary drying and layer combustion area. The materials enter the combustion furnace through the material inlet of the fluidized bed, and are firstly stacked inthe rotary drying and layer combustion area for rotation, drying and partial layer combustion, and continuously input materials extrude the materials subjected to drying and layer combustion out of the rotary drying and layer combustion area and enter the fluidized combustion area for fluidized combustion. By means of the technical scheme in the invention, the problems that in an existing fluidized bed combustion technology, the requirement on the particle size of materials is high, crushing treatment is needed firstly, the energy consumption is large, and the residence time of fuel in a furnace is too short, so that large-particle materials and high-humidity materials cannot be fully combusted are solved.

Owner:JIANGSU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com