Anti-collision device of automatic ultrasonic flaw detection system

An anti-collision device, ultrasonic technology, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, instruments, etc., can solve the problems of easy damage and large loss of probes, and achieve the effect of protection from impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

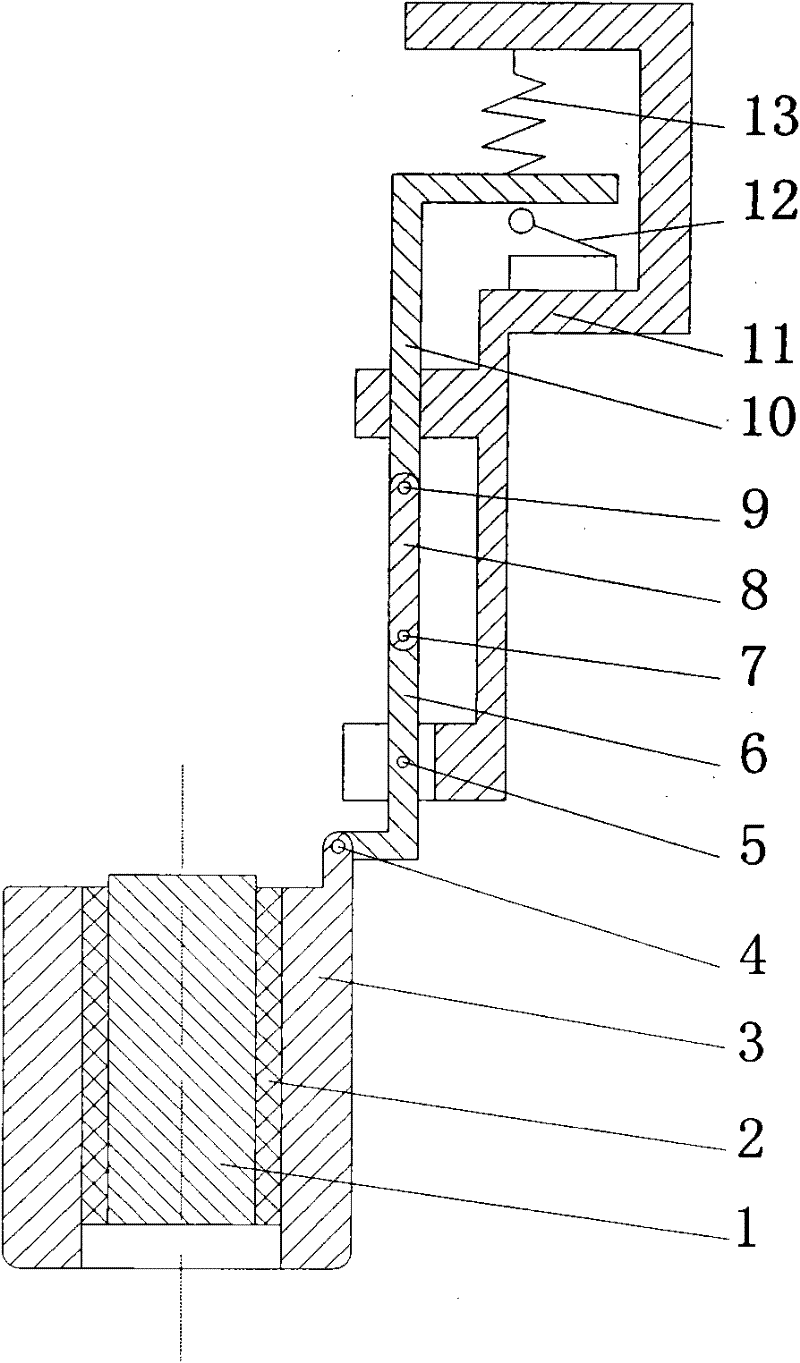

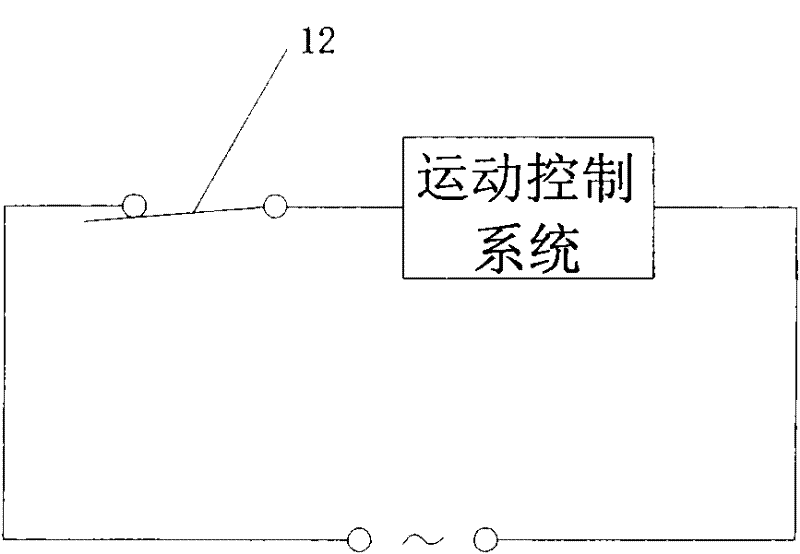

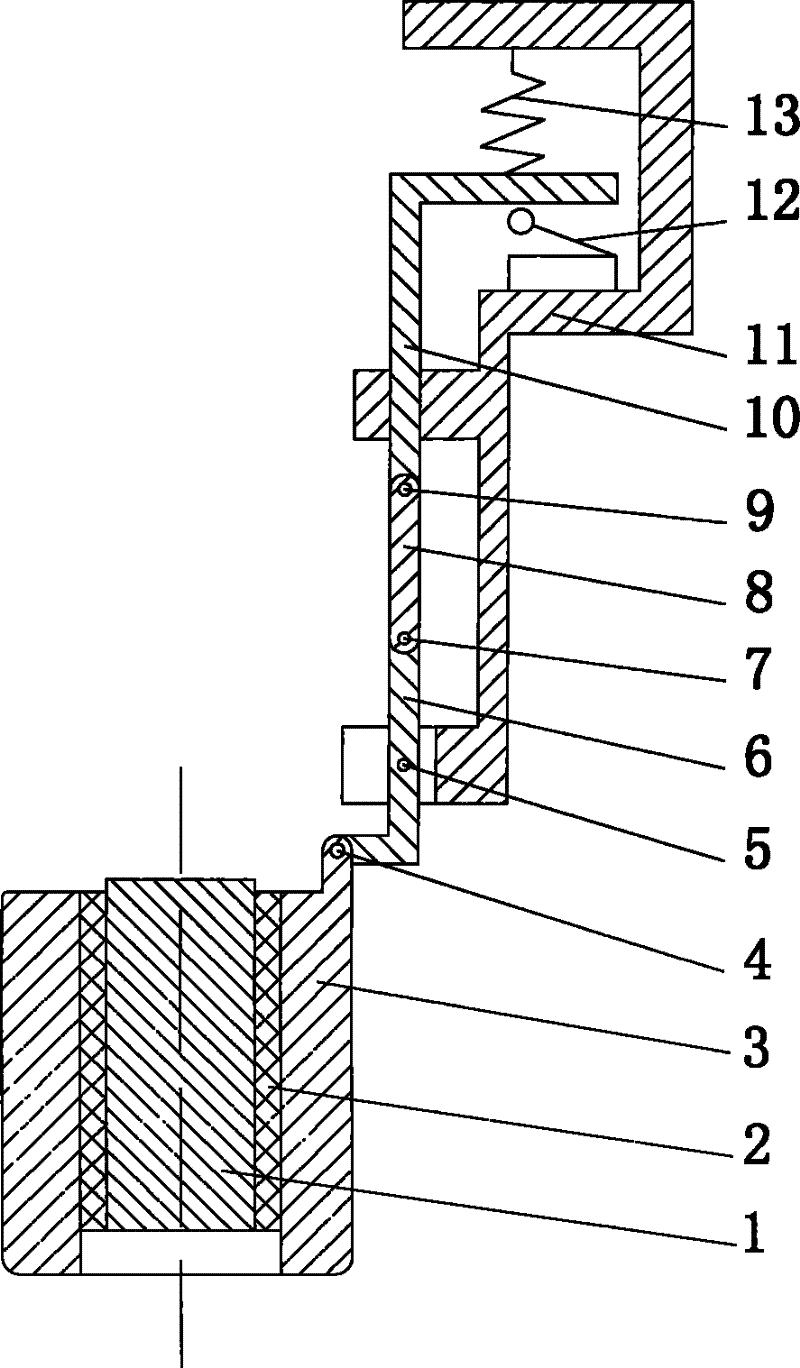

[0015] Such as figure 1 As shown, the present invention is provided with an elastic element 2 on the outside of the probe 1, and the elastic element 2 is covered with a protective cover 3, so that when the probe 1 is about to hit an object, the protective cover 3 hits first, and the elastic element 2 is elastic. Therefore, the probe will not be damaged; the protective cover 3 is connected to one end of the first connecting rod 6 through the first hinge 4, and the middle of the first connecting rod 6 is connected to the fixed frame 11 through the second hinge 5, so the protective cover 3 It can drive the first connecting rod 6 to rotate around the second hinge 5; the other end of the first connecting rod 6 is connected with one end of the second connecting rod 8 through the third hinge 7, and the other end of the second connecting rod 8 is connected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com