A wear-resistant sleeve for an outboard motor starting wheel and an assembly process method thereof

An assembly process and technology for outboard motors, applied in the direction of outboard propulsion devices, transportation and packaging, propulsion device engines, etc., can solve the problems that the insert sleeve body and outboard motor boot cover are easily damaged and have large errors, and achieve The effect of reducing fluffing and breaking, improving the pass rate, and high-precision body quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

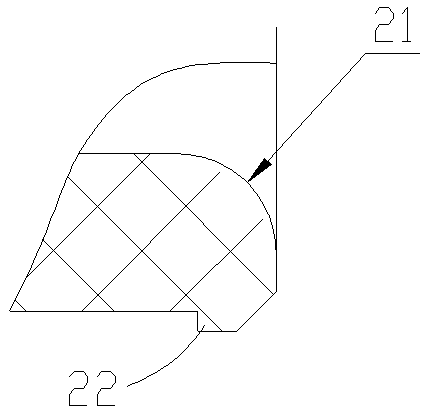

[0037] Example 3 of coating powder: the coating powder is composed of the following materials according to the mass fraction ratio: 75% of ultrafine calcium carbonate with a particle size of 0.01-0.08 μm, 20% of atomized copper powder of -200 mesh, and 0.75% of colloidal graphite. Micro wax powder is 0.75%, binder is 3.5%.

[0038] The adhesive is ceramic tile adhesive or epoxy resin adhesive.

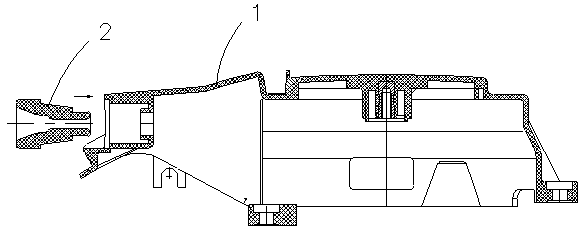

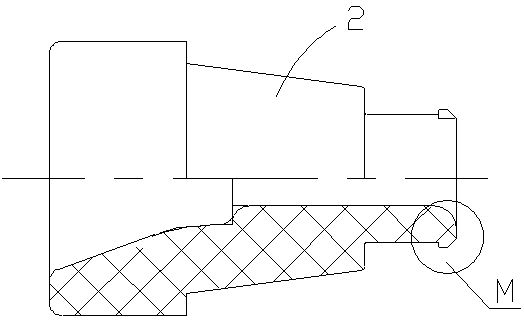

[0039]2. The body 2 of the insert sleeve is pressed into an integrated structure with the boot cover 1 of the outboard motor when the boot cover 1 is thermally expanded. Select various working parameters through the automatic press-in equipment, and control the press-in and pause time.

[0040] 3. When making the insert sleeve body 2, the precision of all the external dimensions of the insert sleeve body 2 is within the range of 0-0.04mm in advance.

[0041] 4. At the same time, when making the insert sleeve body 2, the gap between all the external dimensions of the insert sleeve bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com