Vertical shaft rotation type drawing mechanism for forage grass cutting flatting mill

The technology of a traction mechanism and a flattening machine is applied in the directions of harvesters, agricultural machinery, implements, and mechanical equipment, and can solve the problems of increasing the turning radius of the tractor and being unfavorable for the machine to work on the ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

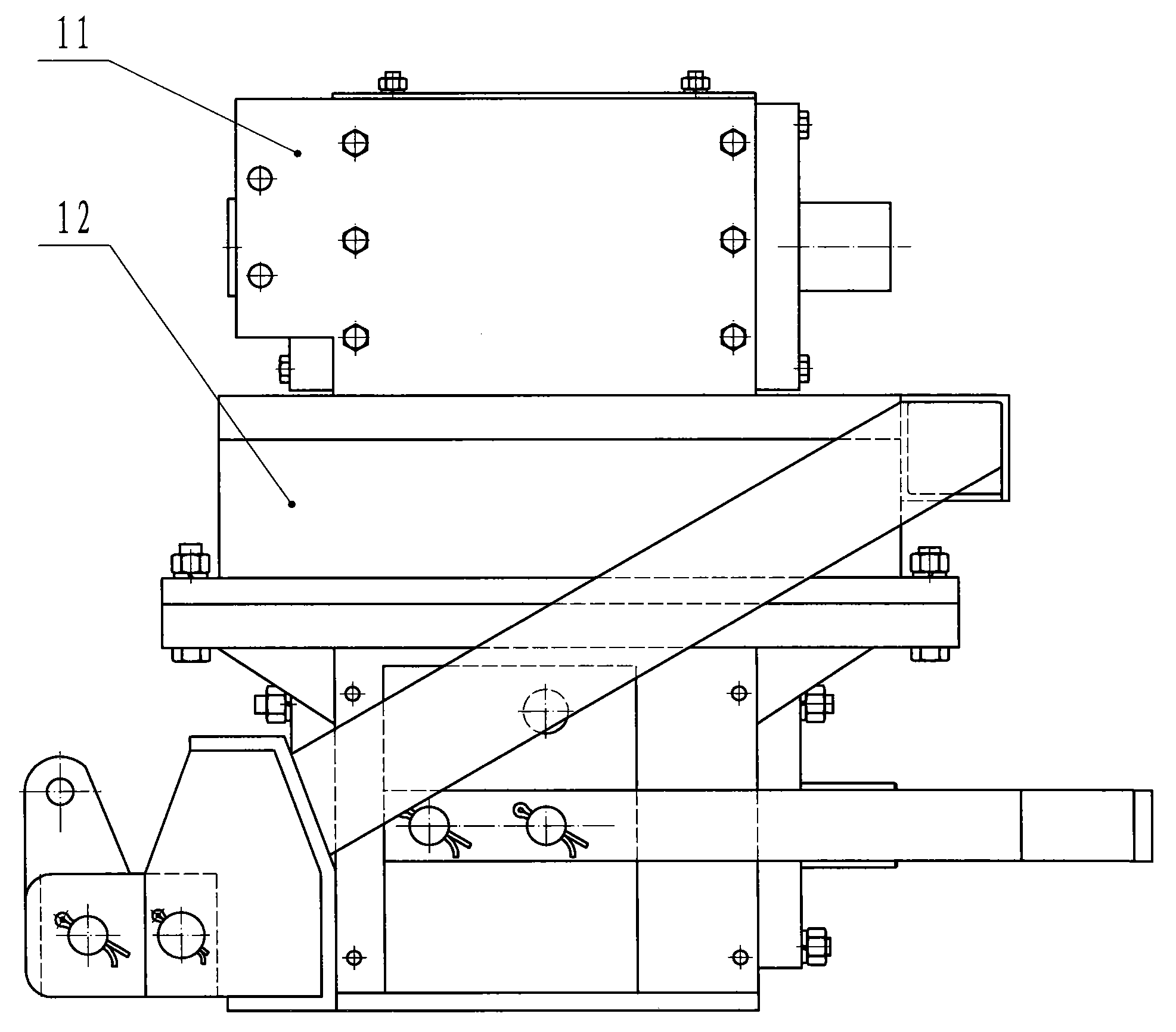

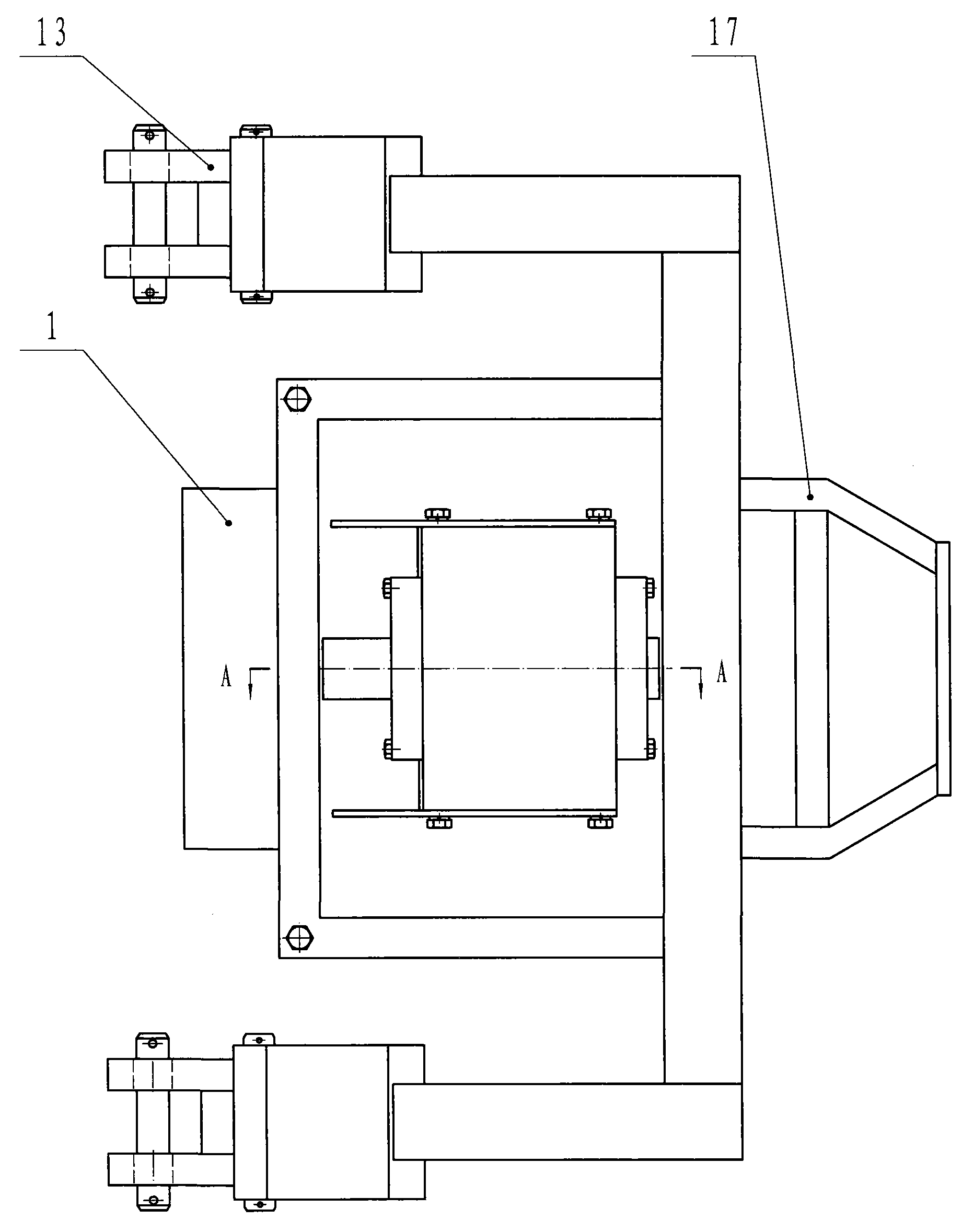

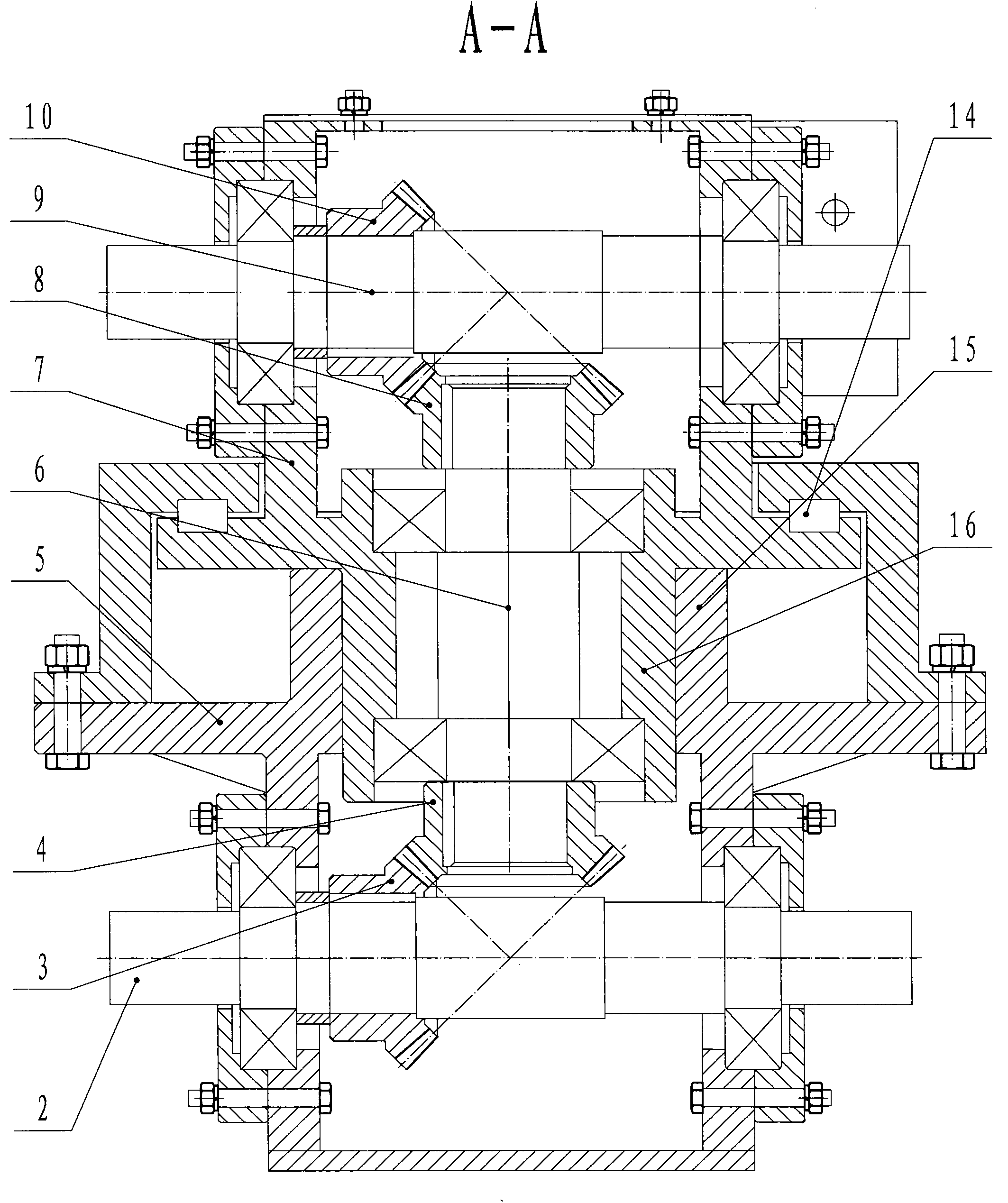

[0011] The present invention comprises: horizontal axis I protective cover 1, horizontal axis I2, bevel gear I3, bevel gear II4, power input box body 5, vertical shaft 6, rotary box body 7, bevel gear III8, horizontal axis 119, bevel gear IV10, connection Plate 11, limit box 12, connecting frame 13, cylindrical roller 14, round sleeve I15, round sleeve II16, support frame 17.

[0012] When working, the tractor transmits power to the horizontal axis I2, and the protective cover 1 of the horizontal axis I is outside the horizontal axis I to protect the exposed part where the horizontal axis I2 connects with the tractor. The bevel gear I3 on the horizontal axis I2 drives the bevel gear II4 to move. The power is transmitted to the vertical shaft 6, the bevel gear III8 rotates simultaneously and drives the bevel gear IV10 to move, the power is transmitted to the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com