Combined type high-power semiconductor chip

A high-power, semiconductor technology, used in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problem of high cost, achieve the effect of eliminating thermal stress, high efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

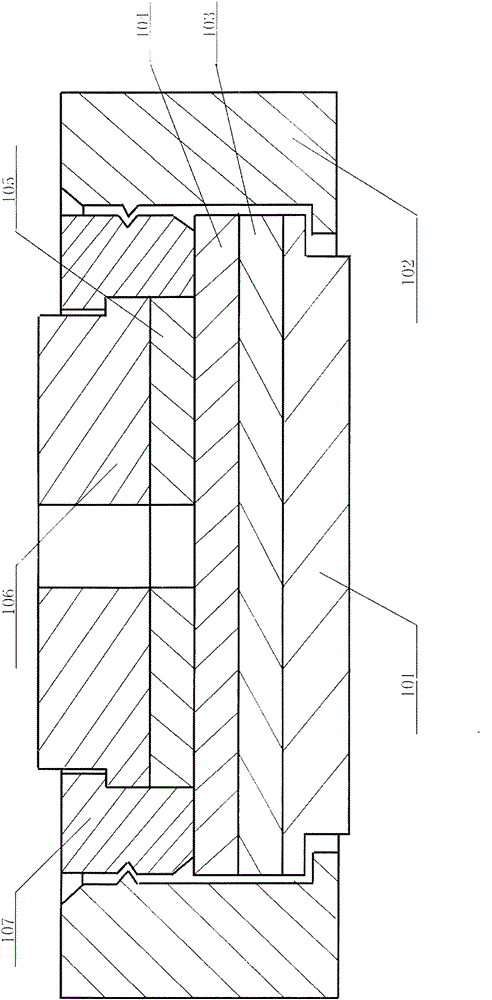

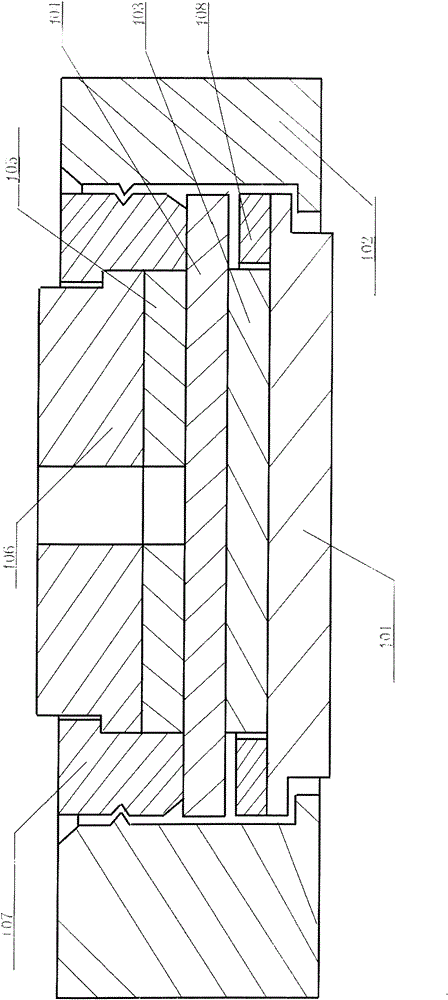

[0011] Such as figure 1 As shown, a combined high-power semiconductor chip includes a package body, a chip, a molybdenum sheet and a copper sheet. The package body is an inner and outer special-shaped annular ring. The upper inner wall of the outer special-shaped annular ring 102 is provided with an inwardly convex snap ring, and the bottom is provided with at least two inwardly convex stoppers. The upper plane of the outer special-shaped annular ring intersects the inner wall. There are chamfers. The outer edge of the inner special-shaped annular ring 107 is provided with a groove that matches the snap ring on the inner wall of the outer special-shaped annular ring, and its upper end is at least provided with two or more inwardly convex stoppers. Chamfers are provided where the planes meet. The inner and outer special-shaped annular rings are made of PPS insulating plastic. A lower copper sheet 101 , a lower molybdenum sheet 103 , a chip 104 and an inner shaped annular rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com