Confined concrete arch frame precise filling device and efficient construction method

A technology that constrains concrete and arches, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve problems such as no grouting system, affecting construction safety, and grout leakage at the grouting port position, achieving good social and economic effects , Guarantee the quality of perfusion construction, and ensure the effect of perfusion compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

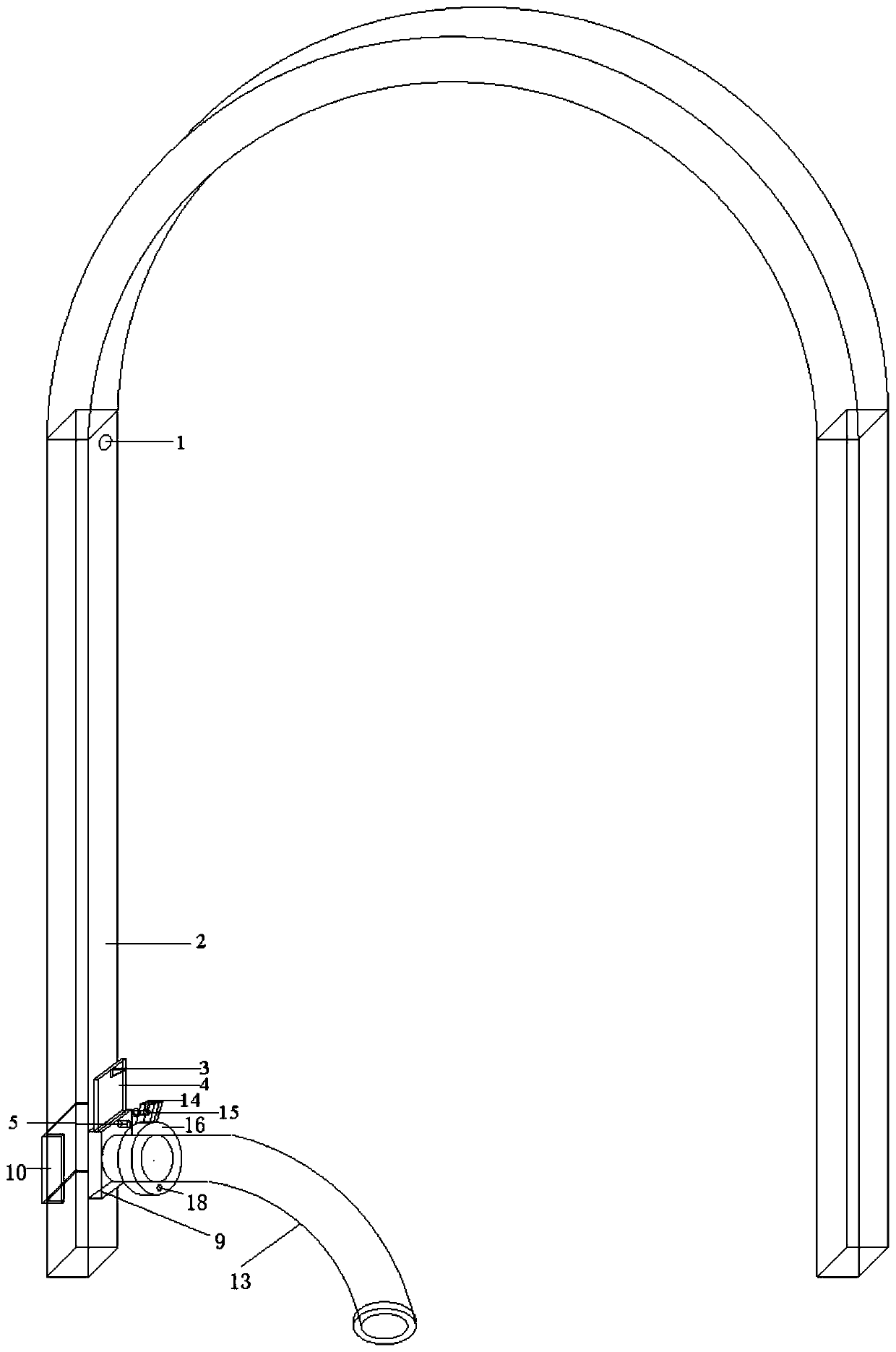

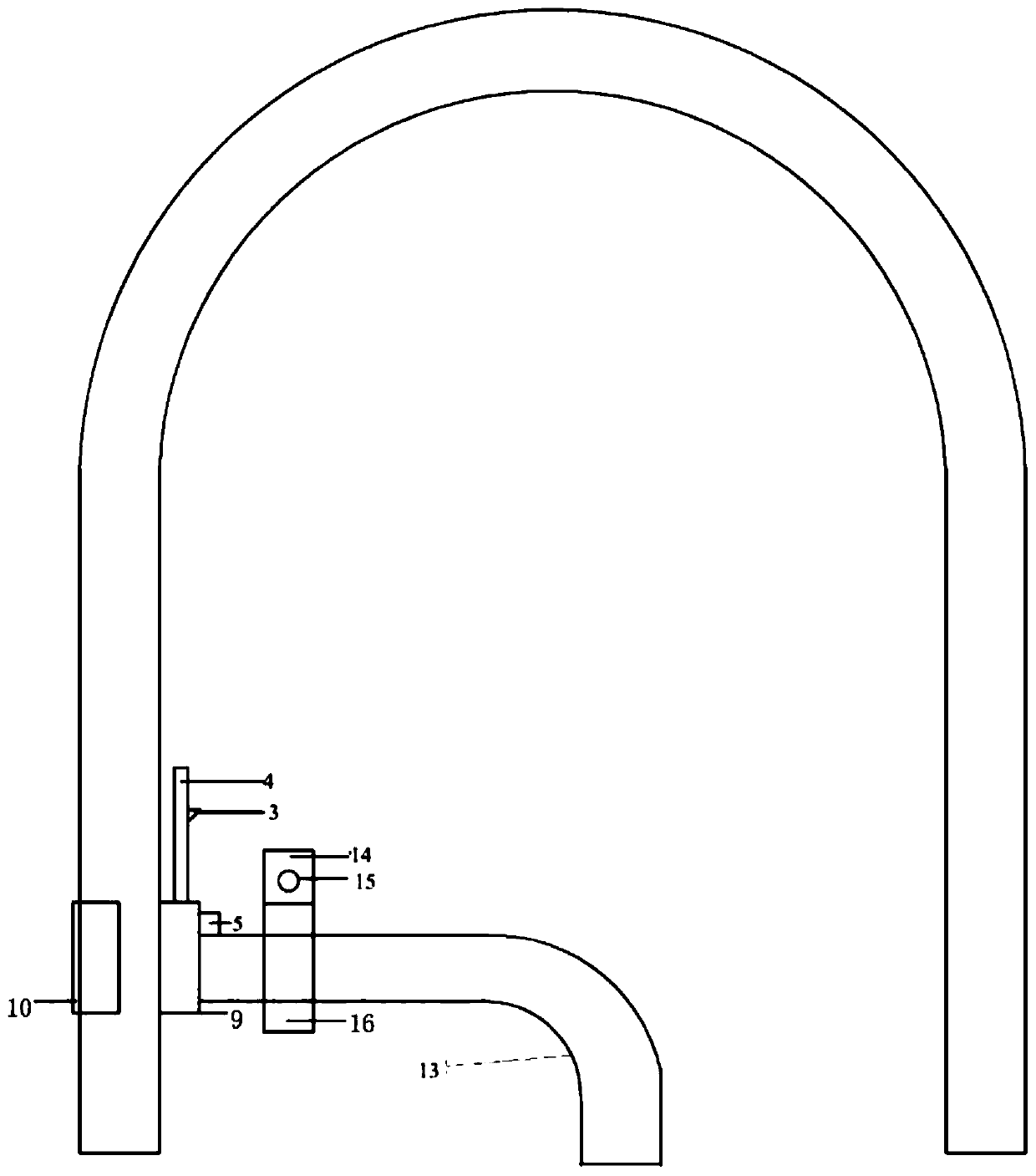

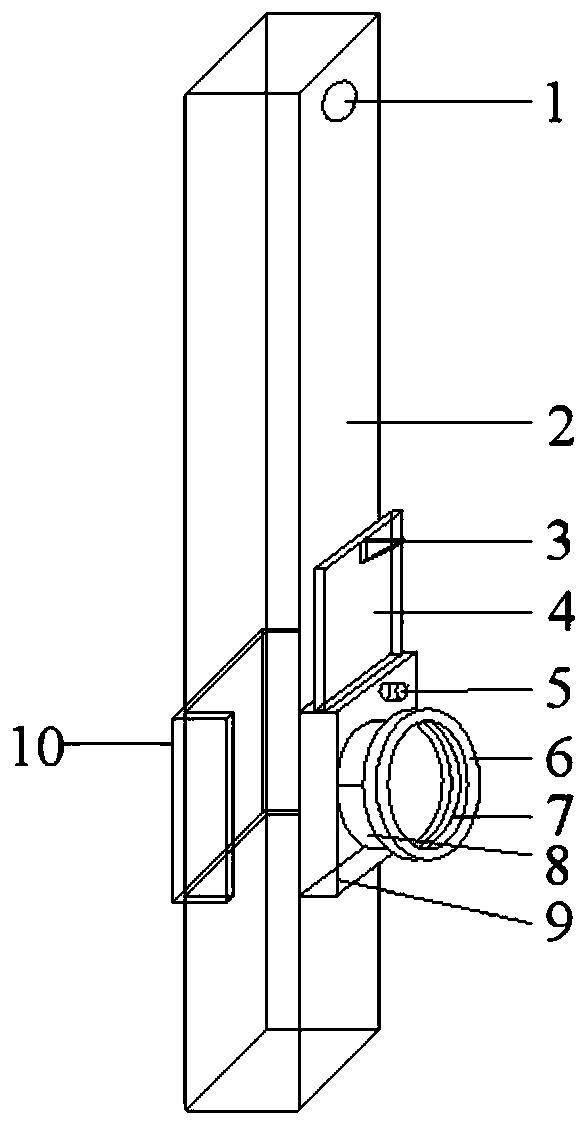

[0039] Attached below figure 1 - attached Figure 5 The perfusion device disclosed in this embodiment is further described;

[0040] Refer to attached figure 1 As shown, the precise pouring device for the constrained concrete arch includes a core pouring component welded on the outside of the bottom of the 2 legs of the constrained concrete arch, a high-strength delivery pipe 13 and a joint ring buckle device; the core pouring component is embedded with the high-strength delivery pipe 13, wherein The inner diameter of the port of the high-strength delivery pipe is smaller than the inner diameter of the connection port at the end of the core perfusion component; the joint buckle device locks the connection port in a circular direction after the perfusion component is connected to the high-strength delivery tube to ensure that the connection port will not be squeezed under high-pressure perfusion open.

[0041] The high-strength conveying pipe 13 can adopt the high-strength a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com