Rear plate type steel-concrete combined section with semi-open grid chamber

A technology of steel-concrete combination and joint section, which is applied to bridge parts, bridge materials, bridges, etc., can solve the problems of inability to give full play to the circumferential support function of the joint section, inconvenience in construction welding and steel bar layout, and increased construction inspection and grouting work It can simplify the structure, save the construction period, and achieve the effect of structural force safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

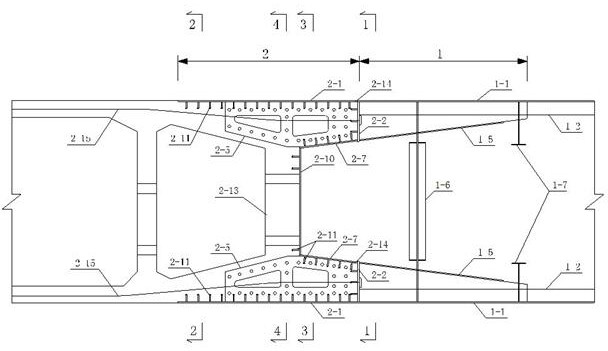

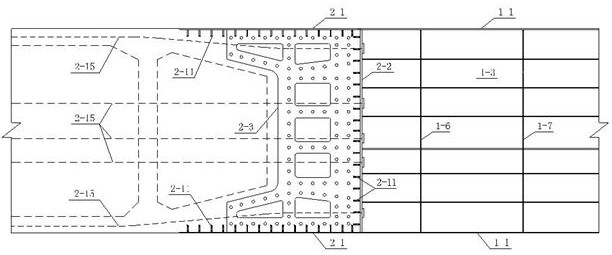

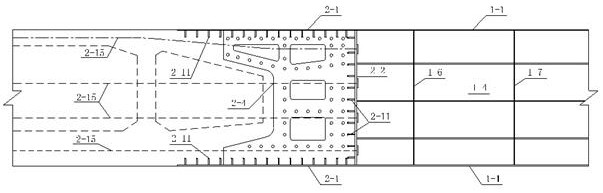

[0041] Such as Figure 1~8 As shown, a steel-concrete combination section of a semi-open cell rear panel includes a steel-concrete combination area 2 fixed to the concrete box girder, and the steel-concrete combination area 2 includes a combination section anchored to each plate of the outer profile of the concrete box girder The peripheral steel plate 2-1, the inner side of the peripheral steel plate 2-1 of the joint section is provided with a steel cell force transmission partition 2-5 along the bridge direction and located in the middle, and the inner side of the peripheral steel plate 2-1 of the joint section is also provided with The rear pressure-bearing steel plate 2-2 in the direction of the transverse bridge, the force-transmitting partition plate 2-5 of the steel cell, and the end of the rear pressure-bearing steel plate 2-2 are provided with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com