Assembly equipment and construction technology for a restrained concrete arch frame

A technology for confining concrete and assembling equipment, which is applied to vertical shaft equipment, mining equipment, earthwork drilling and mining, etc. It can solve problems such as insufficient support bearing capacity, effective control of surrounding rock, and inaccurate positioning, so as to achieve reasonable selection of adjustment position points, The effect of reducing the instability of the face and making the equipment easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

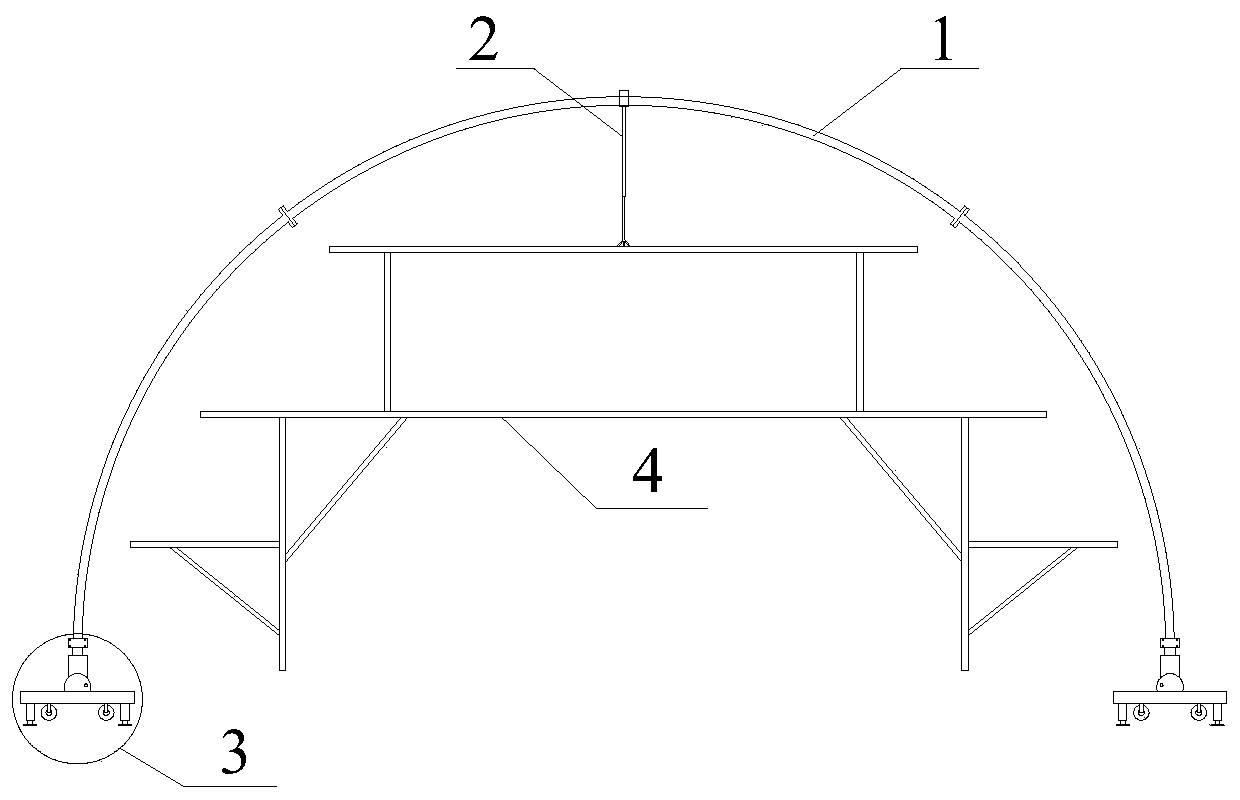

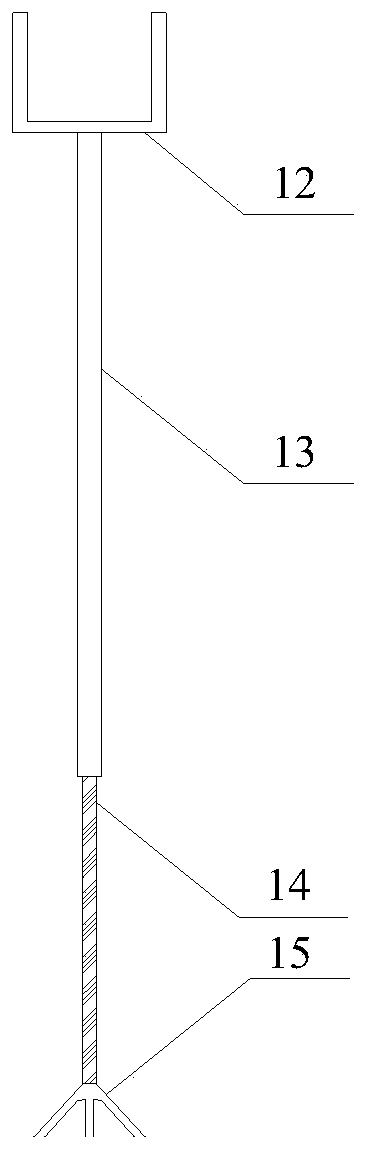

[0052] An assembly device for a constrained concrete arch, including: a constrained concrete arch formwork, which forms a closed space for pouring concrete inside; a positioning operation trolley for adjusting the arch legs on the ground 3. Adjusting the position of the arch The support frame 2, and the laser aligner 18 arranged on the vault and the arch feet on both sides.

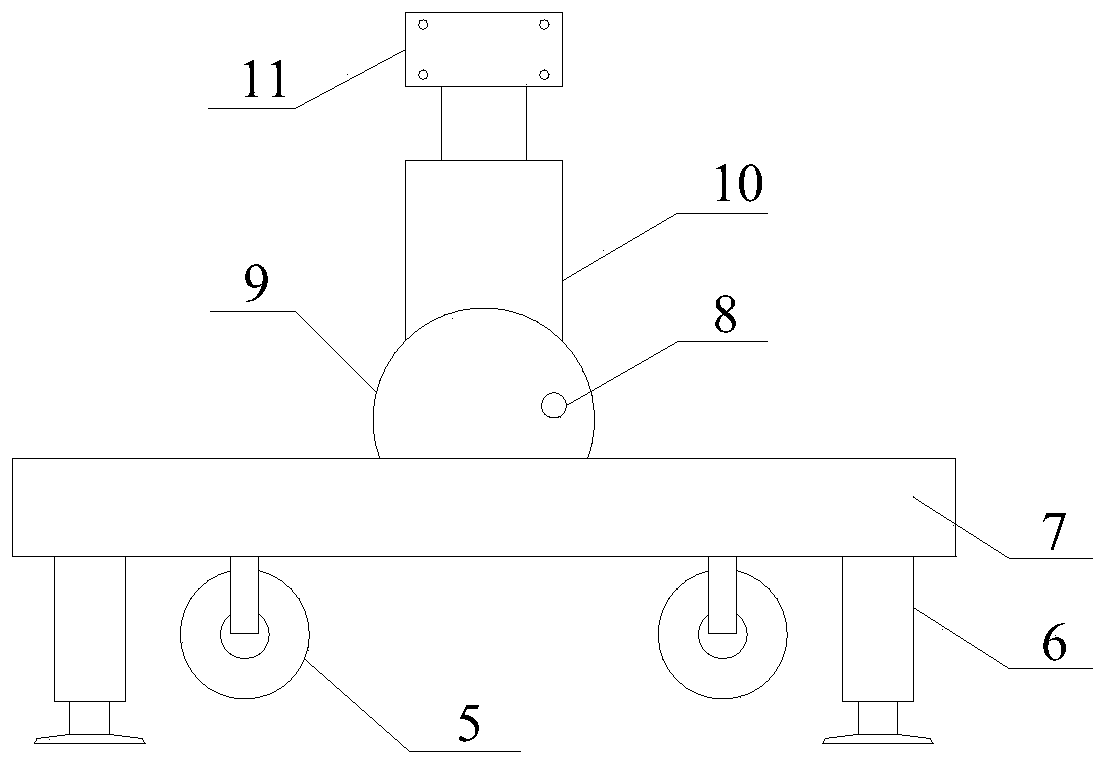

[0053] The positioning operation trolley 3 adjusts the arch legs, specifically including the bottom load-bearing structure composed of tires 5, jacks and platforms 7, the middle support structure composed of rotatable and fixed position adjustment jacks 10, and the upper clamp for constraining the arch legs. Support structure11. Among them, the bearing structure at the bottom of the positioning operation trolley 3 is based on the general tire 5 and platform structure, and four bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com