Precise installing and adjusting method for ton-level optical machine assembly

An installation and adjustment, opto-mechanical technology, applied in installation, optical components, engine frame, etc., can solve the problems of long time consumption, irregularity, different installation and adjustment methods, etc., to ensure surface cleanliness and positioning accuracy. , the effect of improving the adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A precision installation and adjustment method for ton-level optical-mechanical components, comprising the following steps:

[0037] S1. After the optical-mechanical component enters the installation station, use the coordinate measuring equipment to test the external target of the optical-mechanical component to obtain the actual measured position of the optical-mechanical component. The measured position is the current position of the optical-mechanical component represented by the coordinate group value of the external target of the test attitude, wherein the coordinate measuring device is preferably a laser tracker.

[0038] S2. Obtain the target position of the optomechanical component by fitting the measured position with the theoretical position, and calculate the adjustment amount. Specifically, the theoretical position is the pose of the optomechanical component represented by the model and drawings. Due to the existence of the error of the optomechanical compon...

Embodiment 2

[0043] The same part of this embodiment and Embodiment 1 will not be repeated, the difference is:

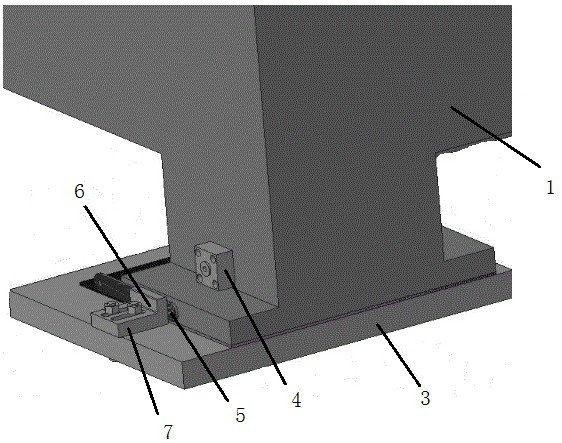

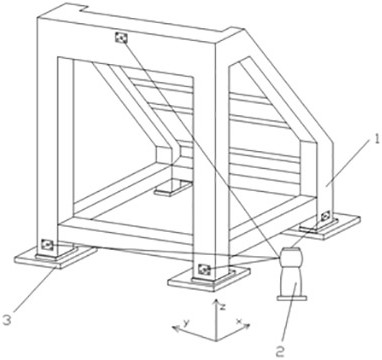

[0044] Such as figure 1 with figure 2As shown, when the supporting device of the optomechanical component is the supporting tool 1, the 6 independent quantities include 3 Z-direction adjustments, 2 X-direction adjustments and 1 Y-direction adjustment, and the supporting tool 1 is set below There are 4 outriggers, select the 3 outriggers that coordinate measuring equipment 2 can see through as the adjustment outriggers, set the target seat 4 on the adjustment outriggers, set the support plate 3 under the adjustment outriggers, and correspond to the adjustment outriggers Offer the fixed block connecting port on the support plate 3.

[0045] Specifically, the coordinate measuring device 2 is used to test the external target of the optomechanical component to obtain the measured position of the optomechanical component. After fitting the measured position and the theoretical posi...

Embodiment 3

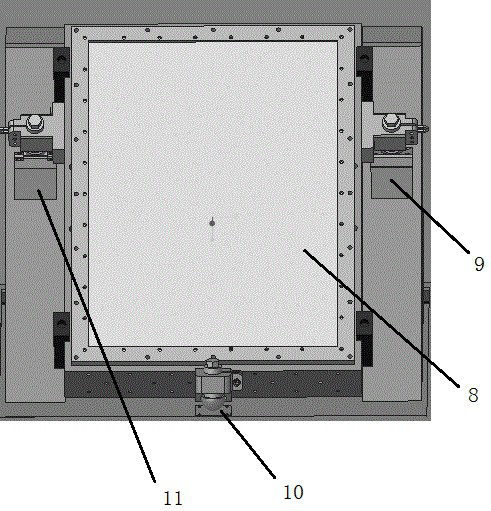

[0051] Such as figure 2 with image 3 As shown, when the supporting device of the optomechanical assembly is a support seat, the target seat is set on the support seat. In this embodiment, the optomechanical assembly is in a tilted state. The supporting seat is a conical support 9, a V-shaped support 11 and a plane support 10, and at the same time, a support plate is provided under the conical support 9, the V-shaped support 11 and the plane support 10. The 6 independent quantities include 3 Z-direction adjustments, 2 Y-direction adjustments and 1 X-direction adjustment. To adjust the X-direction of the conical support 9 or V-shaped support 11 or plane support 10, this In the embodiment, the conical support 9 is adjusted in the X direction, the conical support 9 and the V-shaped support 11 are adjusted in the Y direction, and the conical support 9, the V-shaped support 11 and the plane support 10 are adjusted in the Z direction .

[0052] Specifically, the coordinate measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com