Method for arching treatment of steel clad panel of refueling pool of nuclear power plant

A technology for cladding panels and nuclear power plants, applied in the processing of building materials, industrial buildings, buildings, etc., can solve problems such as inability to fill gaps, and achieve the effects of preventing deformation, precise drilling, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

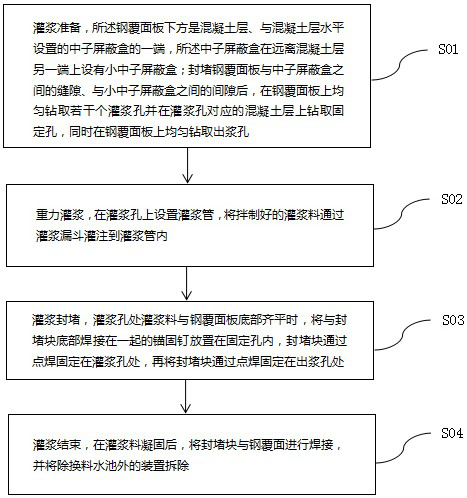

[0044] Such as Figure 1-7 As shown, a method for arching treatment of steel cladding panels in refueling pools of nuclear power plants, the method includes:

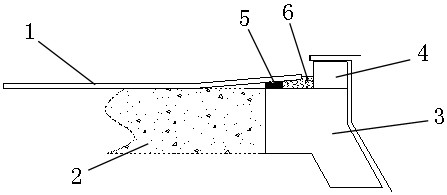

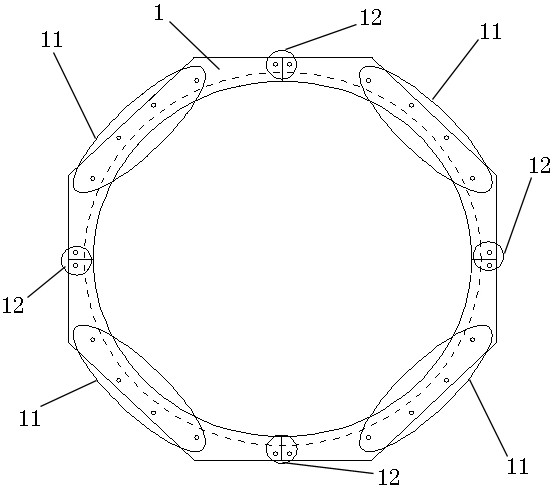

[0045] Step S01, preparation for grouting, under the steel cladding panel 1 is the concrete layer 2 and one end of the neutron shielding box 3 arranged horizontally with the concrete layer 2, and the neutron shielding box 3 is provided on the other end away from the concrete layer 2 Small neutron shielding box 4. After sealing the gap between the steel cladding panel 1 and the neutron shielding box 3, and the gap between the small neutron shielding box 4, drill a number of grouting holes 11 evenly on the steel cladding panel 1 and make corresponding grouting holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com