Semi-fabricated pipe curtain structure and construction technology based on steel-concrete connection

A construction technology and concrete technology, applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems such as the failure to guarantee the bearing capacity and rigidity of the pipe curtain structure, the lack of concrete in the connecting steel pipe, and the insufficient concrete pouring, etc. The effect of concrete pouring quality, control of surface settlement, convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

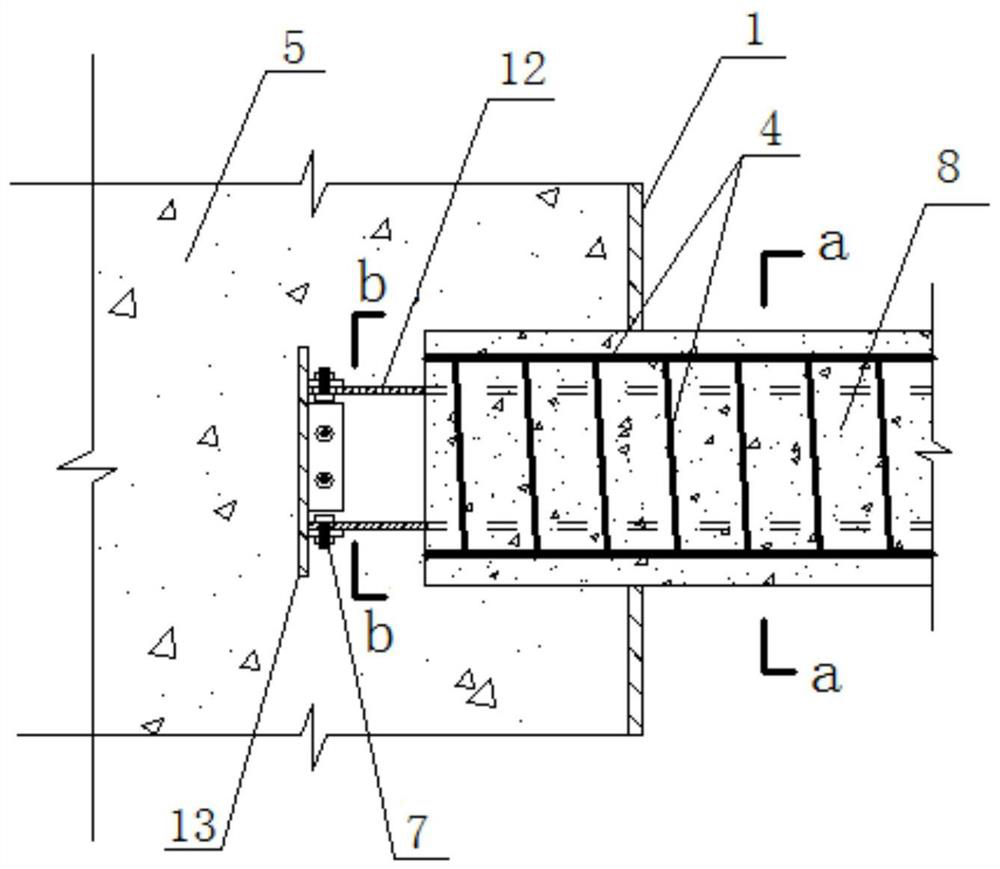

[0044] The prefabricated connecting member in this embodiment is a reinforced concrete connecting member with built-in shaped steel, and the shaped steel in this embodiment is an I-beam.

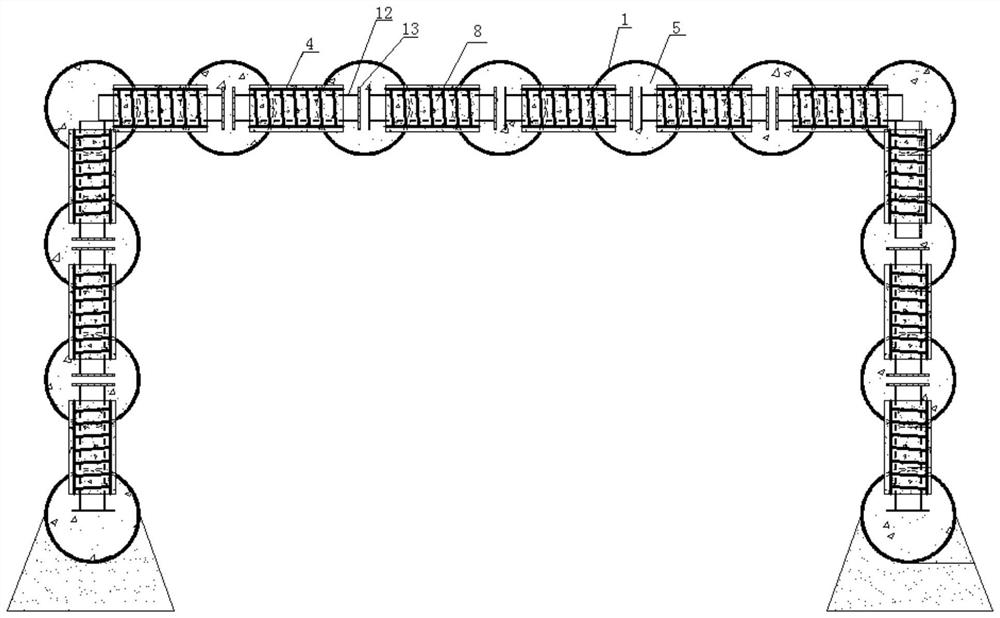

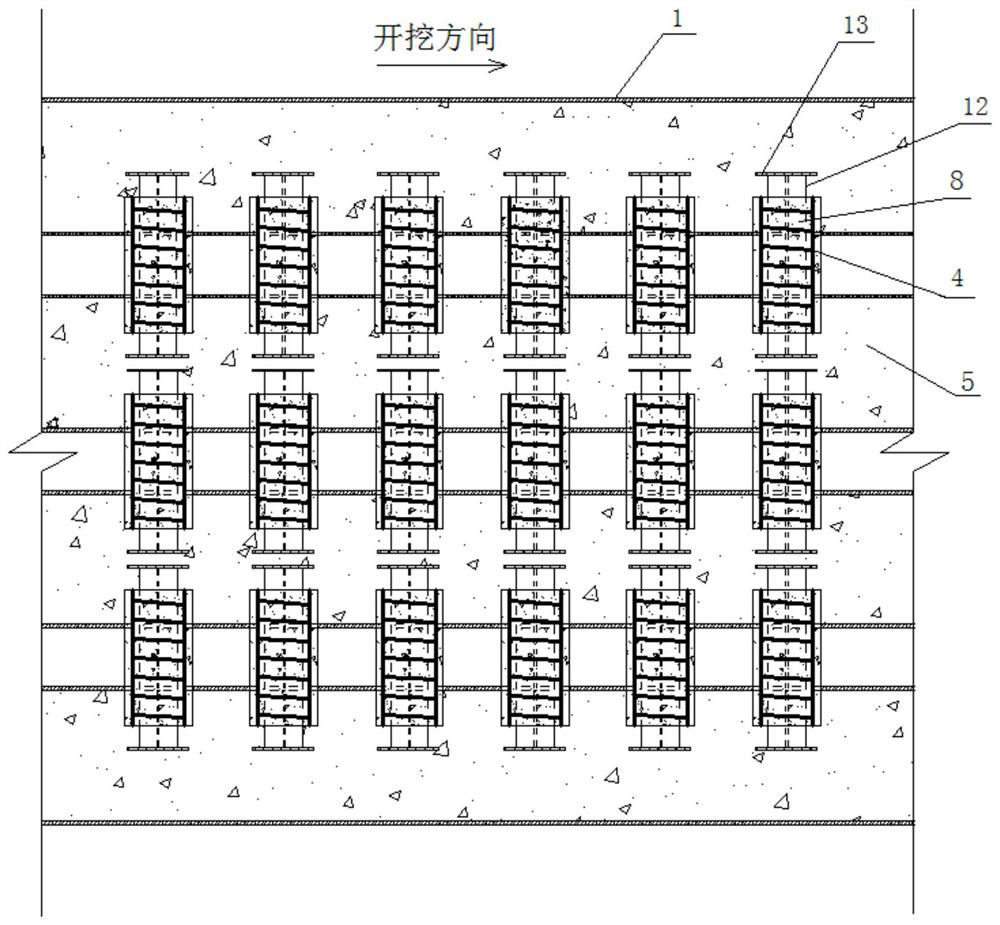

[0045] Such as Figure 1 to Figure 7 As shown, the semi-fabricated pipe curtain structure based on the steel-concrete connection includes a lateral support structure and a lateral support structure. The lateral support structure is used to support the lateral surrounding rock, and the lateral support structure is used to support the ground. The adjacent lateral support structures are connected by lateral support structures, and the lateral support structures are the same as the lateral support structures, both of which include several large steel pipes 1, and the adjacent large steel pipes 1 are connected by prefabricated connecting members, prefabricated The number and diameter of connecting members are determined by calculating the distance and diameter between adjacent large steel pipes 1...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is that the section of the reinforced concrete connecting member with built-in section steel is circular, such as Figure 8 to Figure 10 shown.

Embodiment 3

[0061] The prefabricated connecting member in this embodiment is a steel pipe concrete connecting member with built-in shaped steel, and the shaped steel in this embodiment is an I-beam.

[0062] Figure 11 to Figure 16 As shown, the semi-fabricated pipe curtain structure based on the steel-concrete connection includes a lateral support structure and a lateral support structure. The lateral support structure is used to support the lateral surrounding rock, and the lateral support structure is used to support the ground. The lateral support structures are connected by a lateral support structure, the lateral support structures and the lateral support structures include several large steel pipes 1, and the adjacent large steel pipes 1 are connected by a prefabricated connecting member, the cross section of the prefabricated connecting member is It is circular, and the axis of the prefabricated connecting member is perpendicular to the axis of the large steel pipe 1. The large st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com