Rock-socketed oblique pile impact-drilling and pile-forming construction process

A construction technology and inclined pile technology, applied in the direction of impact drilling, drilling tools, earthwork drilling, etc., can solve the problems of lack of pile forming technology and less research on inclined piles, so as to ensure the quality of piles and ensure piles. Slope, the effect of ensuring perfusion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

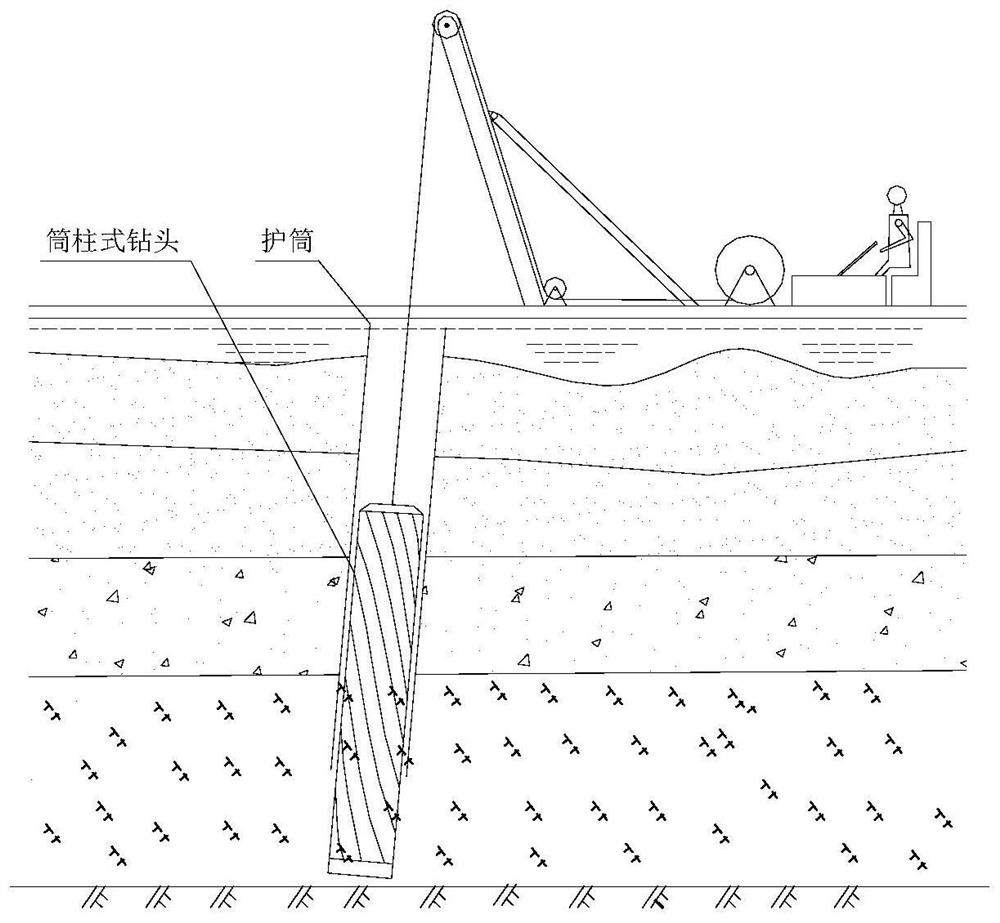

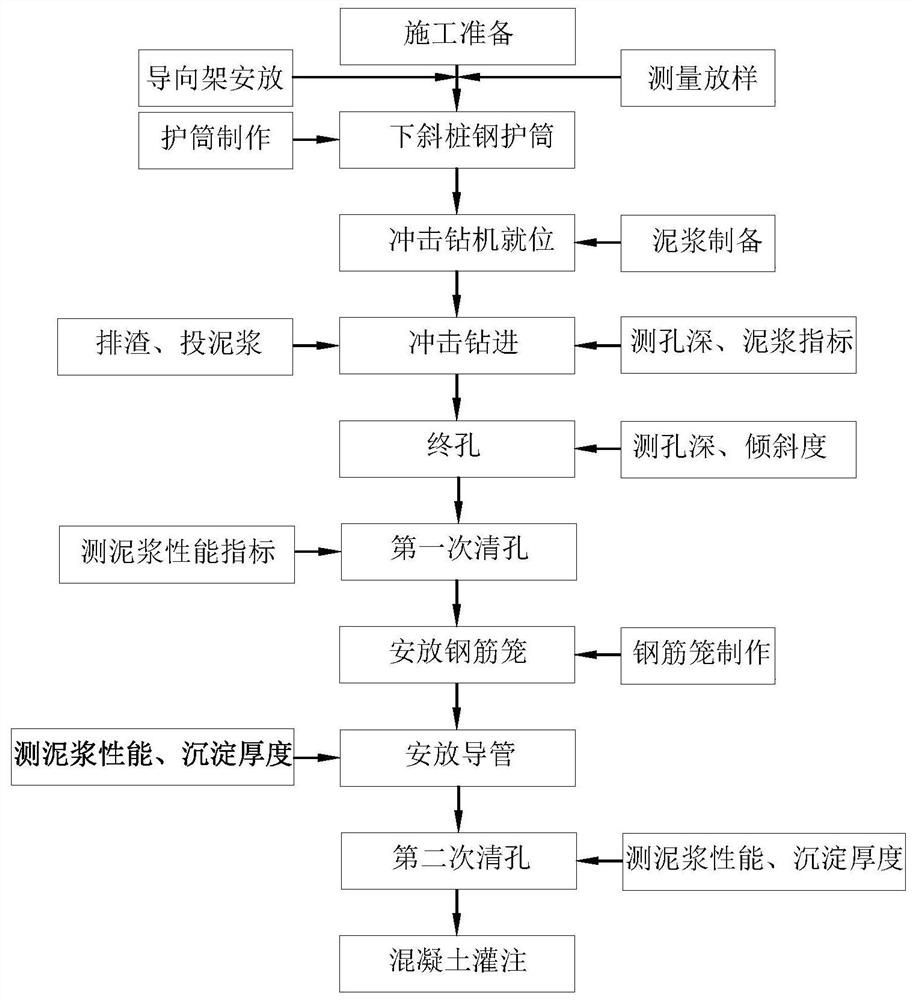

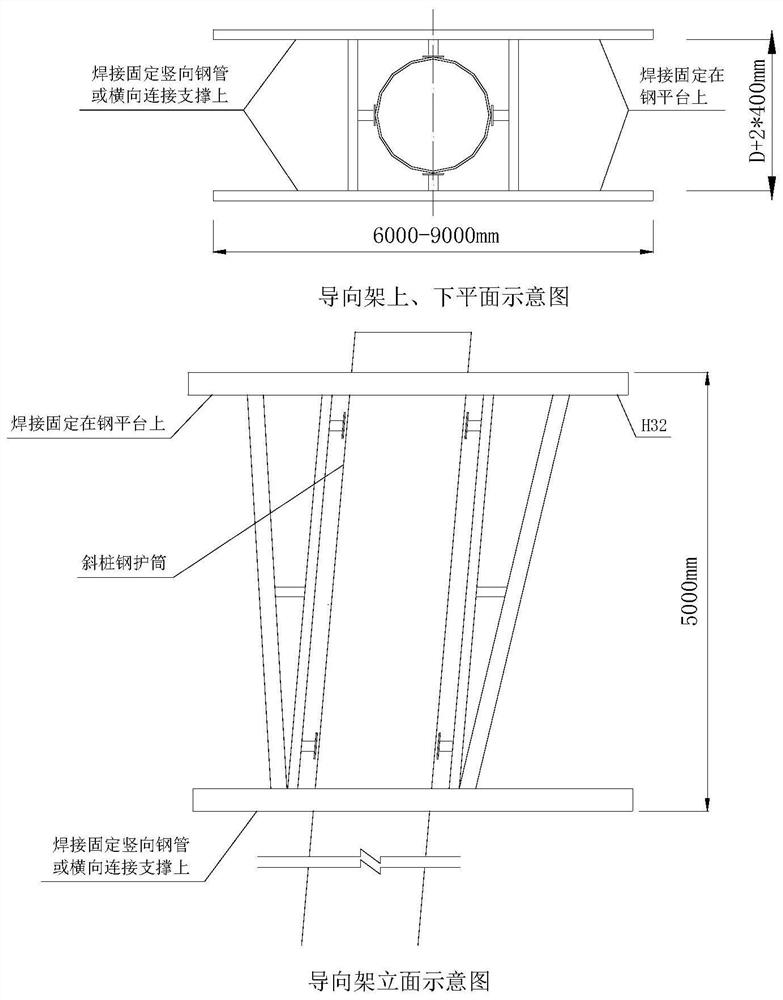

[0034] Such as Figure 1-Figure 9 As shown, a construction technique of percussion drilling for rock-socketed inclined piles provided in this embodiment is suitable for slopes less than 1:5 (perpendicularity is about 88.5 degrees), pile diameters are 600-1500mm, and pile lengths are not suitable. For inclined piles greater than 45m and less than 6m outside the bottom of the steel casing, the steps are as follows:

[0035] S1. Construction preparation stage: After construction personnel enter the construction site, level the site, build construction access roads or construction platforms to facilitate heavy vehicles to travel and construct, lay out lines according to the requirements of the design and construction drawings, and release the pile positions on the ground or at the elevation of the platform. The focus is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com