Construction technology of continuous-span common-column C-shaped stock yard

A construction technology and stockyard technology, which is applied to the processing of building materials, columns, pier columns, etc., can solve the problems that the C-shaped stockyard construction technology cannot be used and the construction space is limited, so as to improve construction efficiency and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

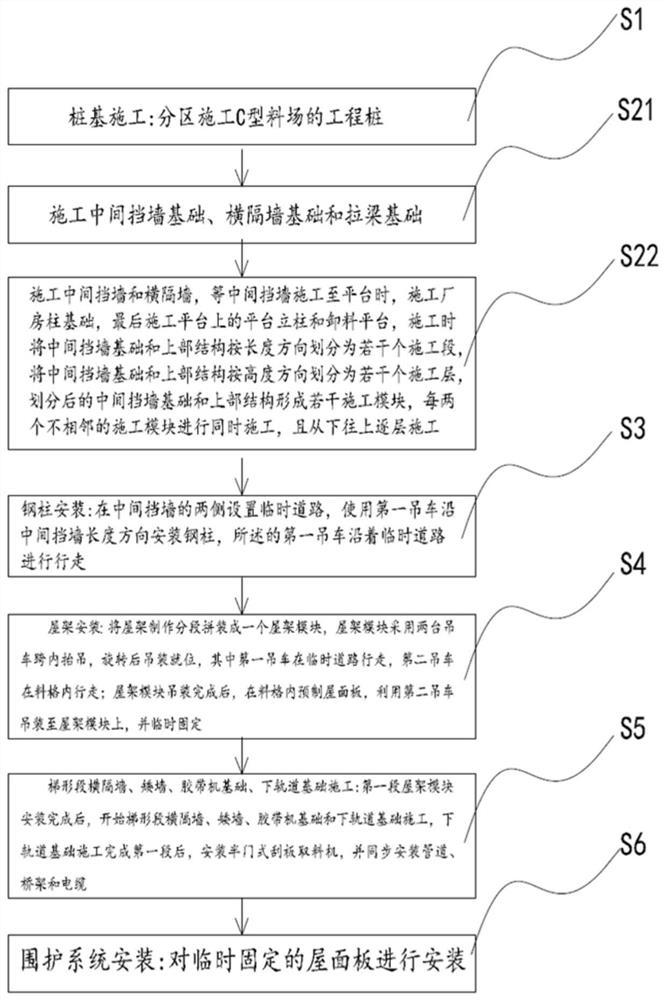

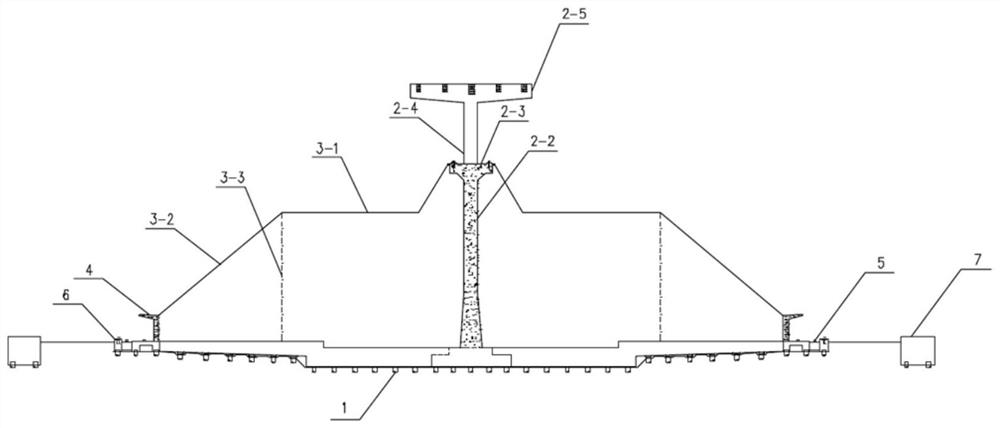

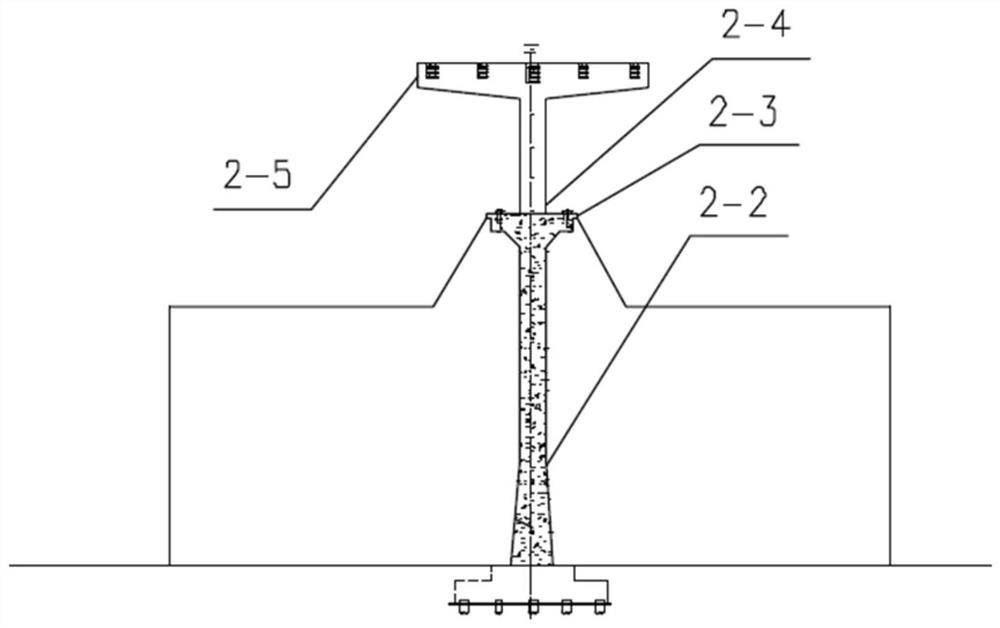

[0039] Such as Figure 1-10 As shown, in order to solve the construction technical problems under the severely limited construction space of the C-shaped material yard with continuous spans and co-columns, the present invention provides an embodiment, which is specifically as follows: A construction process for a C-shaped material yard with continuous spans and co-columns , including the following steps:

[0040] S1. Pile foundation construction: construction of engineering pile 1 of the C-type stockyard in different areas, specifically: construct the PHC pipe pile (prestressed high-strength concrete pipe pile) of the stockyard body first, and reduce the squeeze of the PHC pipe pile by arranging stress release holes Soil effect; CFG piles (cement fly ash gravel piles) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com