A construction method for a highly variable loading and unloading platform

A construction method and a technology for feeding and discharging materials, which are applied in the processing of building materials, construction, building construction, etc., and can solve the problems of low safety of steel pipe fastener-type feeding and discharging platforms, difficulty in ensuring verticality deviation, and limited strength of steel pipes, etc. , to achieve the effect of solving the technical problems in the construction of the loading and unloading platform, high reusability and fast erection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

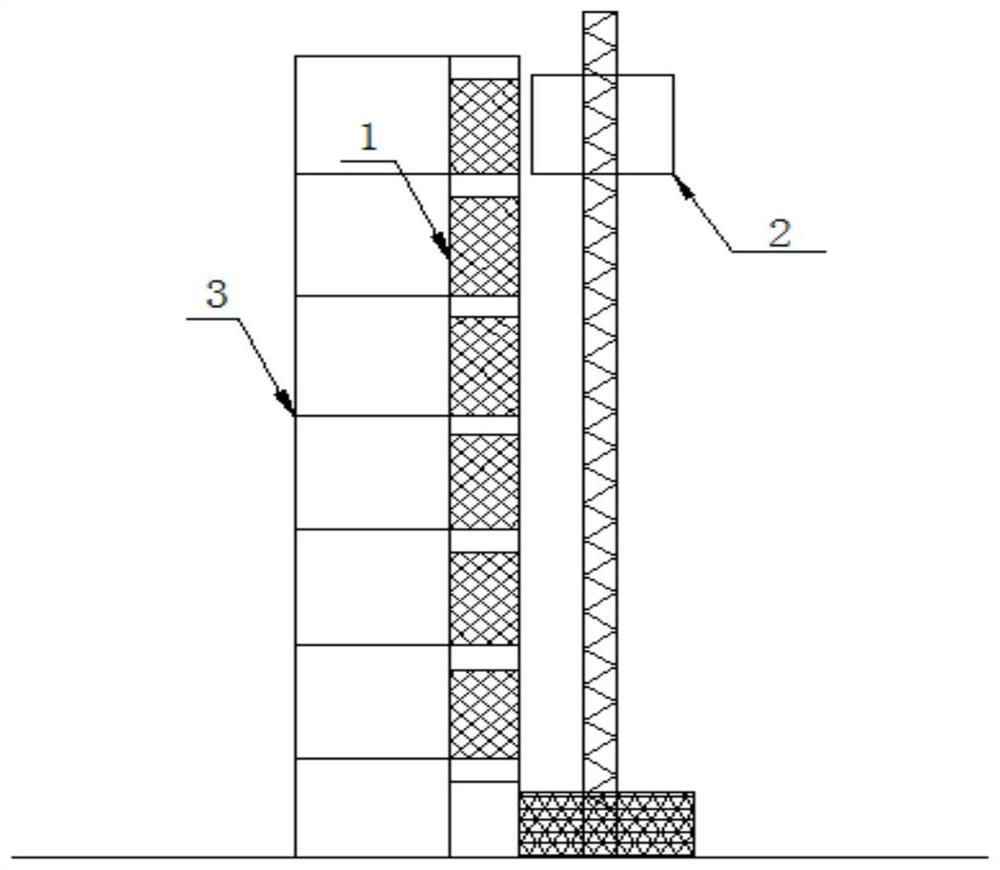

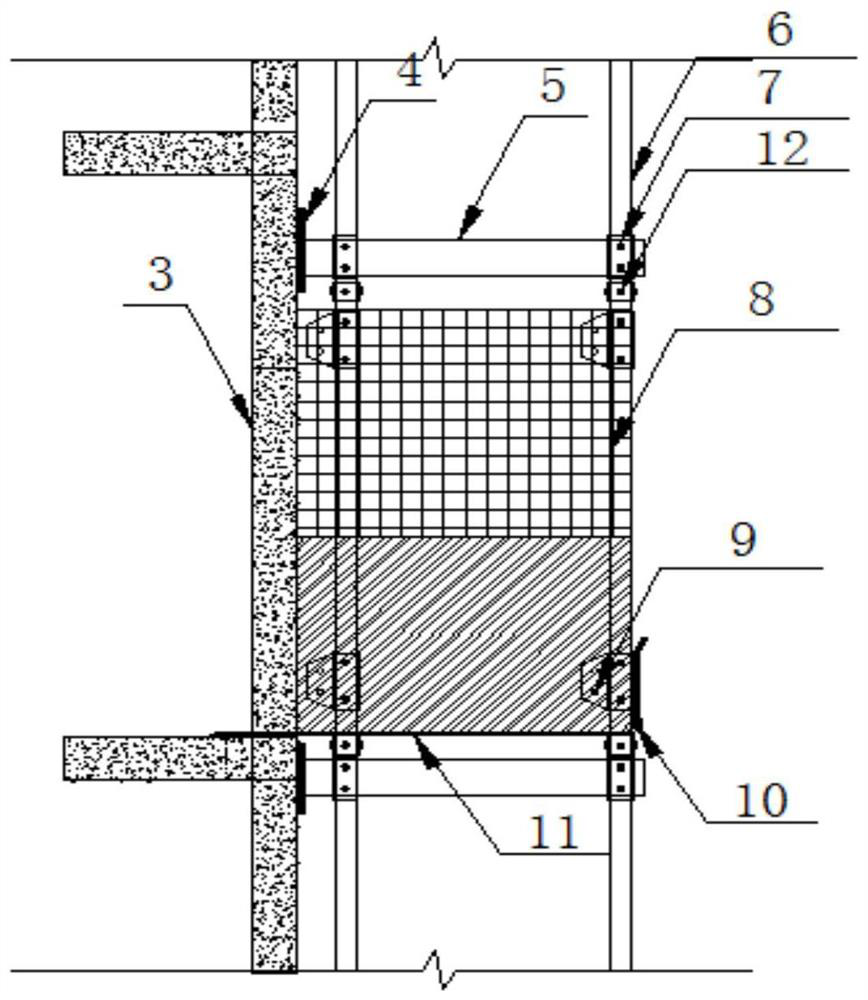

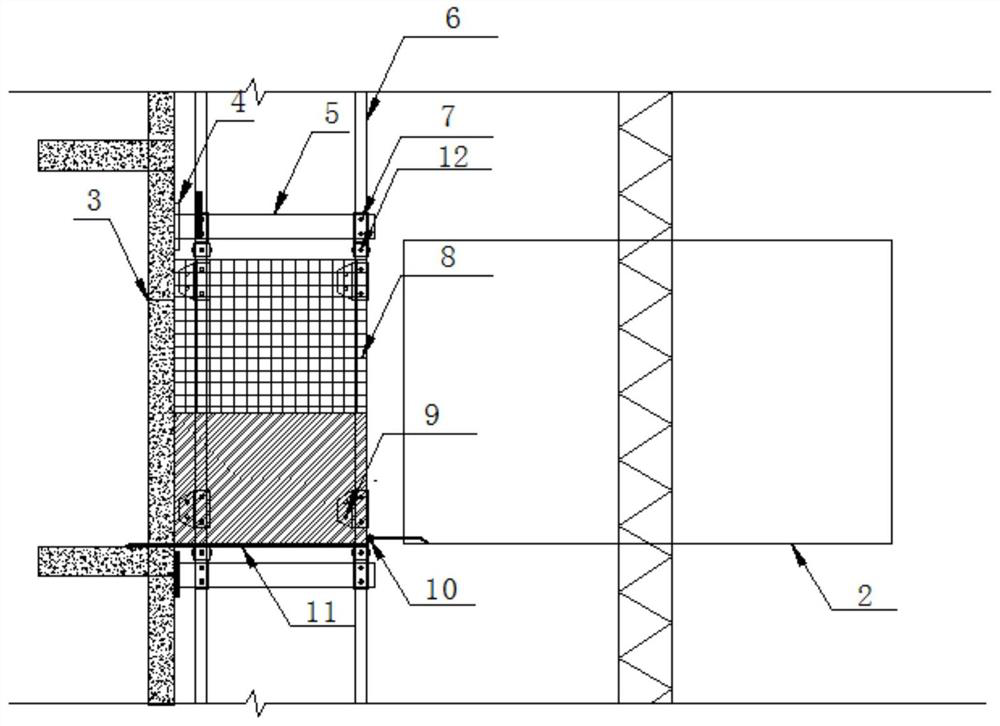

[0020] like Figure 1-4 As shown in the figure, a construction method for a highly variable loading and unloading platform includes the following steps:

[0021] 1) Measuring and setting out: First, measure and set out on the building frame (building structure), as the reference line during the construction of the loading and unloading platform. When installing the platform frame (longitudinal column, horizontal column), use the vertical line of the reference line and The horizontal line is used as the reference line for installation;

[0022] 2) Installation of the frame of the loading and unloading platform: first install the inner longitudinal column row and the outer longitudinal column row on one outer side of the building frame 3 (the side close to the building frame 3 is called the inner longitudinal column row, and the side far from the building frame 3 is called the inner longitudinal column row. It is the outer longitudinal column row), the inner longitudinal column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com