High-speed railway aluminium alloy track plate pressing device

A technology of aluminum alloy track and pressing device, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of large waste of human resources, damage to the track plate, less use times, etc., to achieve more turnover, improve work efficiency, The effect of reverse luck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

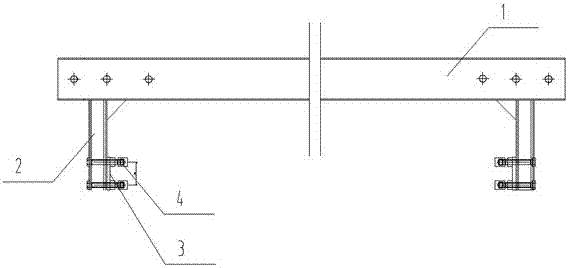

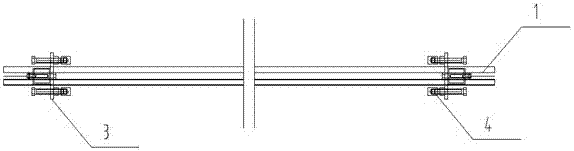

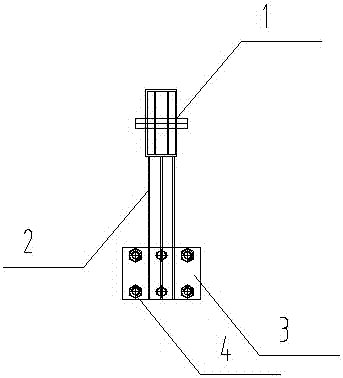

[0024] Embodiment 1: A high-speed rail aluminum alloy track plate pressing device, including: a pressing bar 1, a leg 2, a side fixing plate 3, a pressing rod, and a tightening screw 4; the pressing bar 1 and the supporting leg 2 are welded vertically form a door shape; the side fixing plate 3 is placed parallel to the lower end of the leg 2, and is connected with the leg 2 by bolts; the compression rod 4 is connected to the track base plate and the pressure bar 1, and is pre-installed with the track base plate. The openings are connected by steel bars; the tightening screw 4 tightens the edge sealing formwork through the side fixing plate 2; the legs 2 and the side fixing plate 3 are made of aluminum alloy. The outriggers are quadrangular aluminum profiles, which are extruded once by extrusion equipment; reinforcing bosses are arranged in the direction of the top tightening; the side fixing plates are aluminum alloy plates, which are processed and formed by mechanical processi...

Embodiment 2

[0025] Embodiment 2: On the basis of Embodiment 1, the Rp0.2 of the aluminum alloy is 250 MPa; the tensile strength is greater than 280 MPa. The aluminum alloy grade is 6061, alloy state: T6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com