Treatment method of elevation-exceeding part of concrete pouring pile head

A treatment method and concrete technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high labor intensity, damage to the main reinforcement bars, and inability to guarantee the quality of the project, and achieve the effect of ensuring the quality of pouring and easy treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

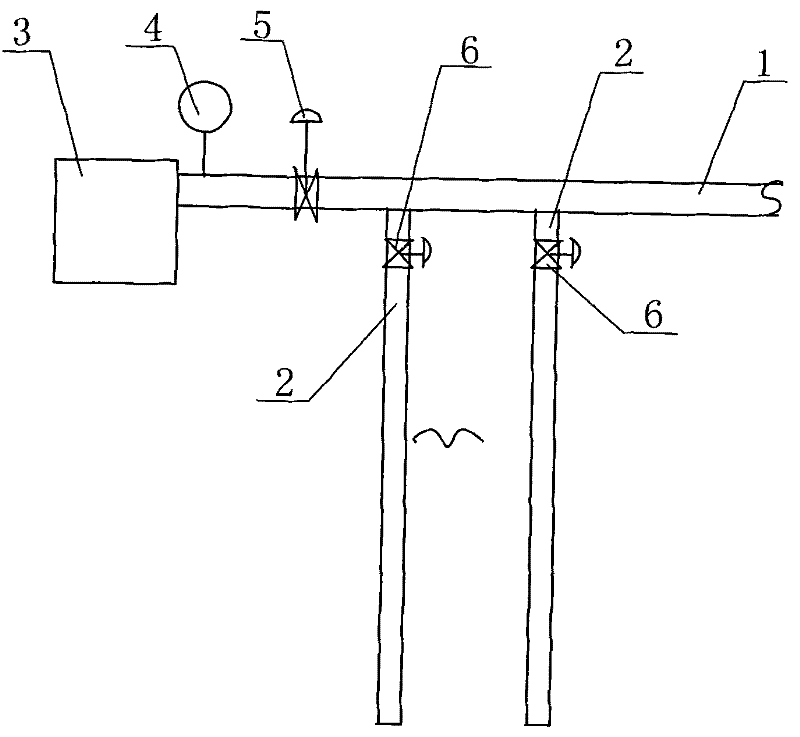

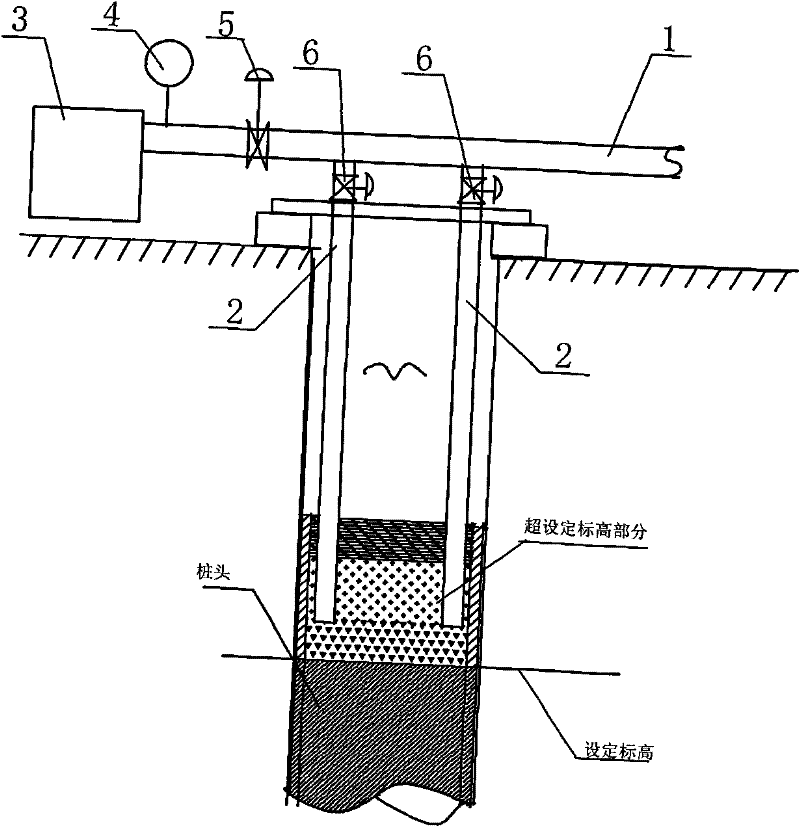

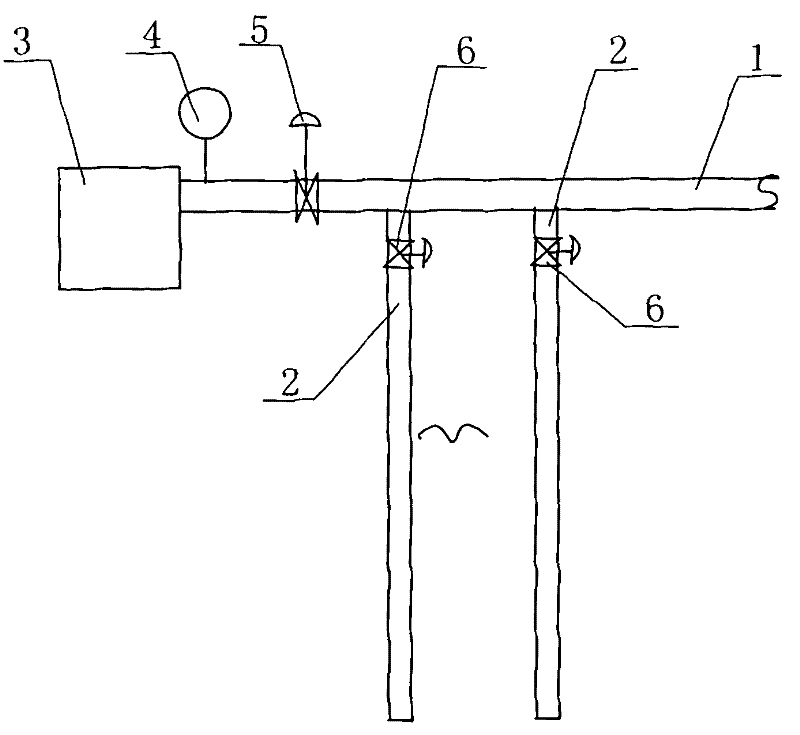

[0020] The method of processing the super-elevation part of the concrete pouring pile head, the steps:

[0021] 1) 2 minutes after the concrete pouring pipe was pulled out, insert the compressed air branch pipe 2 of the treatment device for the super-elevation part of the concrete pouring pile head into the concrete. The distance between the elevations is required to be calibrated at 100 mm, so the compressed air branch pipe 2 is inserted into the concrete without adjustment;

[0022] 2) Open the regulating valve 6 on the compressed gas branch pipe 2 and the regulating valve 5 on the compressed gas main pipe 1 of the treatment device for the super-elevation part of the concrete pouring pile head, so that the compressed gas with a pressure of 0.4Mpa passes through the compressed gas branch pipe 2 The bottom sprays out around;

[0023] 3) Three minutes after the surface layer of the poured concrete begins to appear grout bubbles, close the regulating valve 5 on the compressed g...

Embodiment 2

[0027] The method of processing the super-elevation part of the concrete pouring pile head, the steps:

[0028] 1) 4.5 minutes after the concrete pouring pipe was pulled out, insert the compressed air branch pipe 2 of the treatment device for the super-elevation part of the concrete pouring pile head into the concrete. The distance between elevations is required to be calibrated at 200 mm, so the compressed gas branch pipe 2 is inserted into the concrete without adjustment;

[0029] 2) Open the regulating valve 6 on the compressed gas branch pipe 2 and the regulating valve 5 on the compressed gas main pipe 1 of the treatment device for the super-elevation part of the concrete pouring pile head, so that the compressed gas with a pressure of 0.6Mpa passes through the compressed gas branch pipe 2 The bottom sprays out around;

[0030] 3) 4.5 minutes after grout bubbles appear on the surface of the poured concrete, close the regulating valve 5 on the compressed air main pipe 1 an...

Embodiment 3

[0034] The method of processing the super-elevation part of the concrete pouring pile head, the steps:

[0035] 1) 5 minutes after the concrete pouring pipe was pulled out, insert the compressed air branch pipe 2 of the treatment device for the super-elevation part of the concrete pouring pile head into the concrete. The distance between elevations is required to be calibrated at 300 mm, so the compressed gas branch pipe 2 is inserted into the concrete without adjustment;

[0036] 2) Open the regulating valve 6 on the compressed gas branch pipe 2 and the regulating valve 5 on the compressed gas main pipe 1 of the processing device for the super-elevation part of the concrete pouring pile head, so that the compressed gas with a pressure of 0.7Mpa passes through the compressed gas branch pipe 2 The bottom sprays out around;

[0037] 3) 6 minutes after the poured concrete surface begins to appear grout bubbles, close the regulating valve 5 on the compressed gas main pipe 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com