Construction method for underwater non-dispersing self compact concrete

A technology of self-compacting concrete and construction method, which is applied in the direction of basic structure engineering, construction, etc., can solve the problems of concrete strength not meeting the design requirements, segregation, etc., reduce the risk of unsuccessful back sealing, simple construction operation, and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

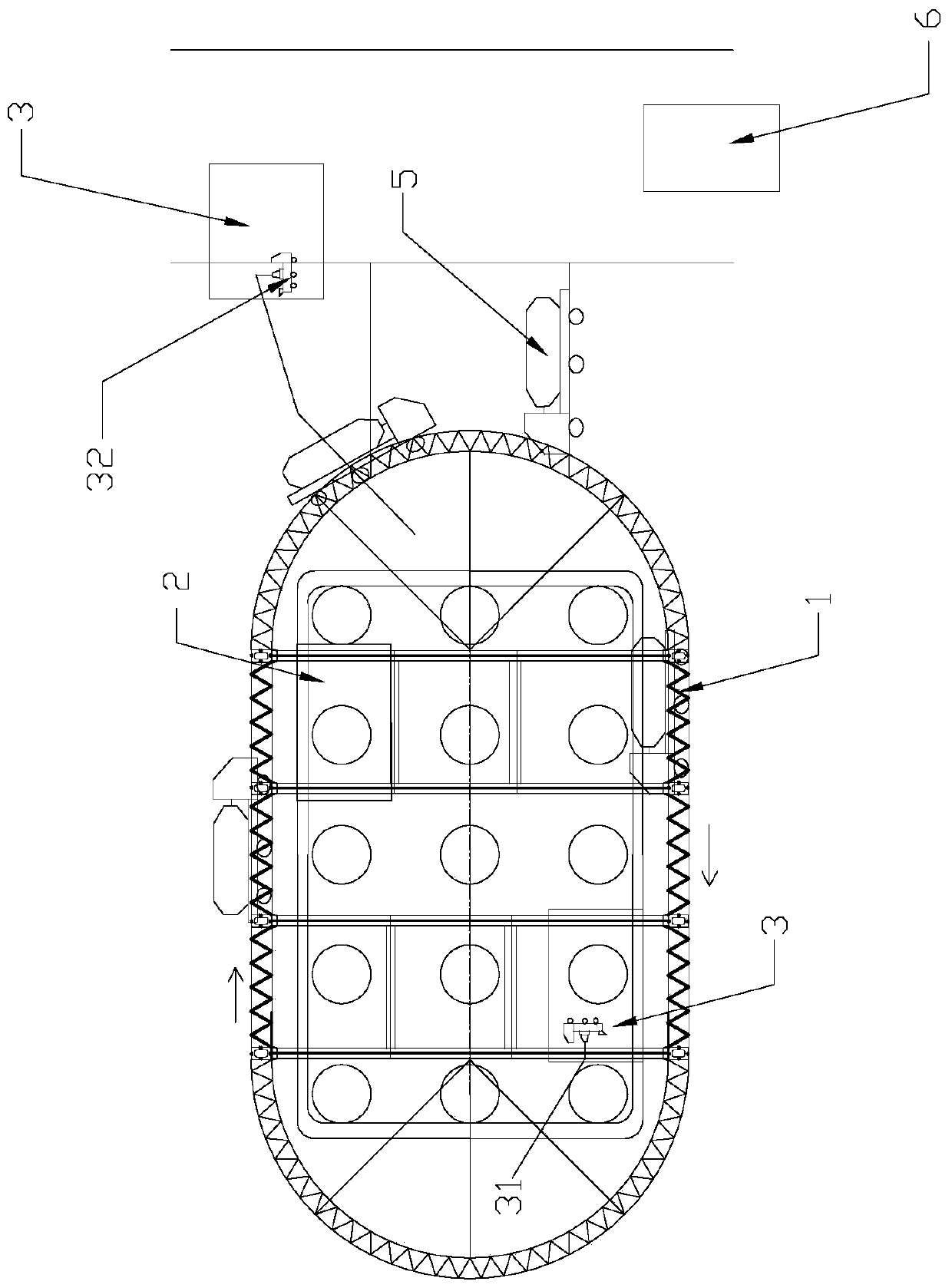

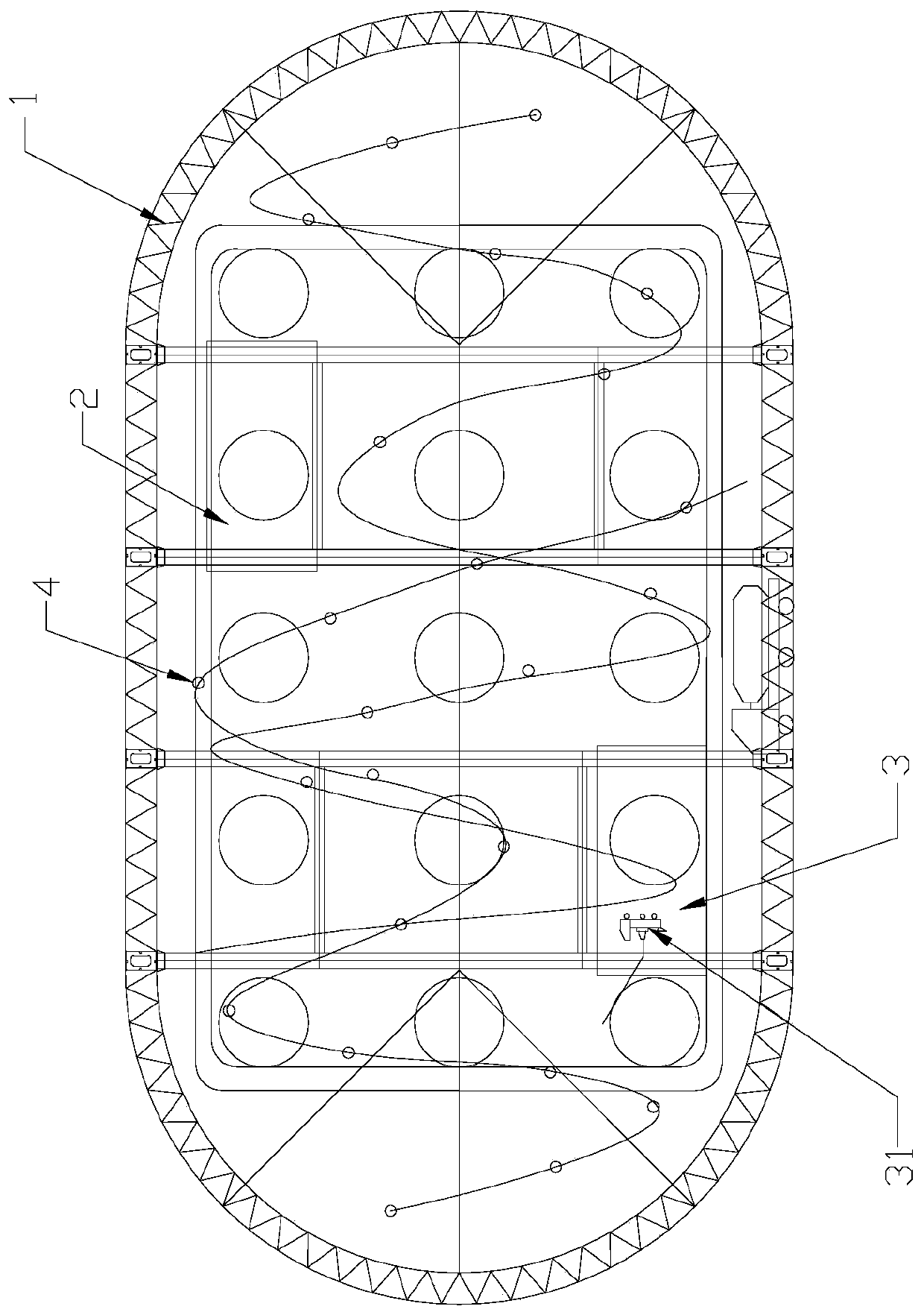

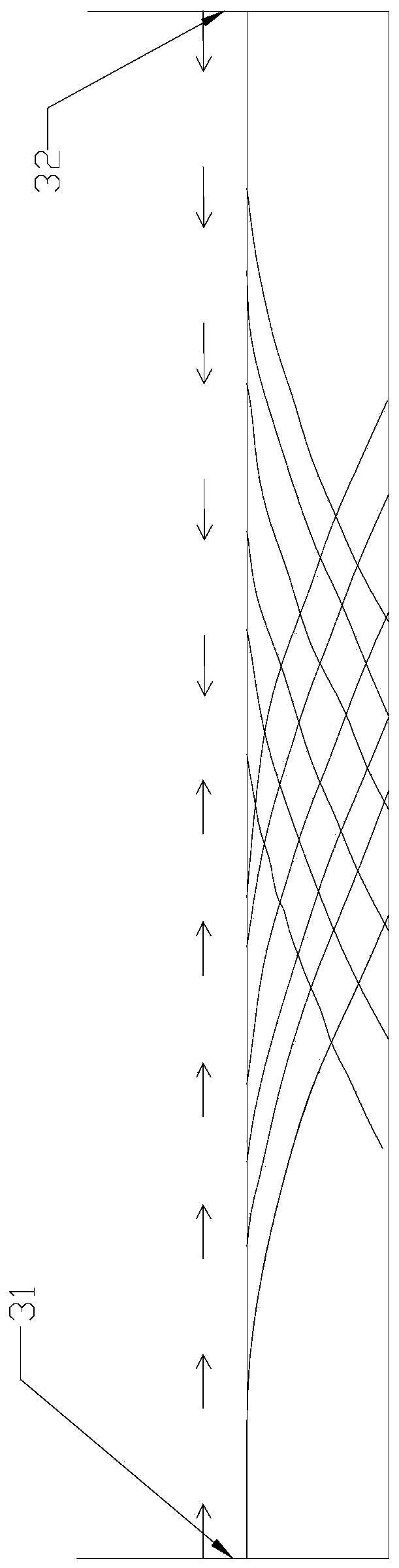

[0020] refer to Figure 1 to Figure 3 , the present invention is a kind of underwater non-dispersive self-compacting concrete construction method, and it comprises the following steps:

[0021] S1: Set up the site. Specifically, during underwater foundation construction, a pit is dug for drainage, and a cofferdam 1 is built around the foundation pit as a temporary water retaining facility. The cofferdam 1 circles around the foundation pit, including a closed circle formed by a square in the middle and a semicircle at both ends. There is a trestle bridge with a width of 6m near the cofferdam 1 as a traffic bridge, and there is a self-built mixing station 200m away from the opposite bank of the river, and two sets of 3m 3 Compulsory mixing building, 6 sets 8m 3 Concrete tank truck 5, concrete tank truck 5 can move on cofferdam 1. 2 sets of concrete pumps, 4 conduits, the underwater non-dispersible self-compacting concrete passes through the conduits, and is poured by its own...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com