Concrete pouring device and method

A technology of concrete and pouring concrete, applied in construction, infrastructure engineering and other directions, can solve problems such as failure, complicated structure of conduit head, etc., and achieve excellent results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

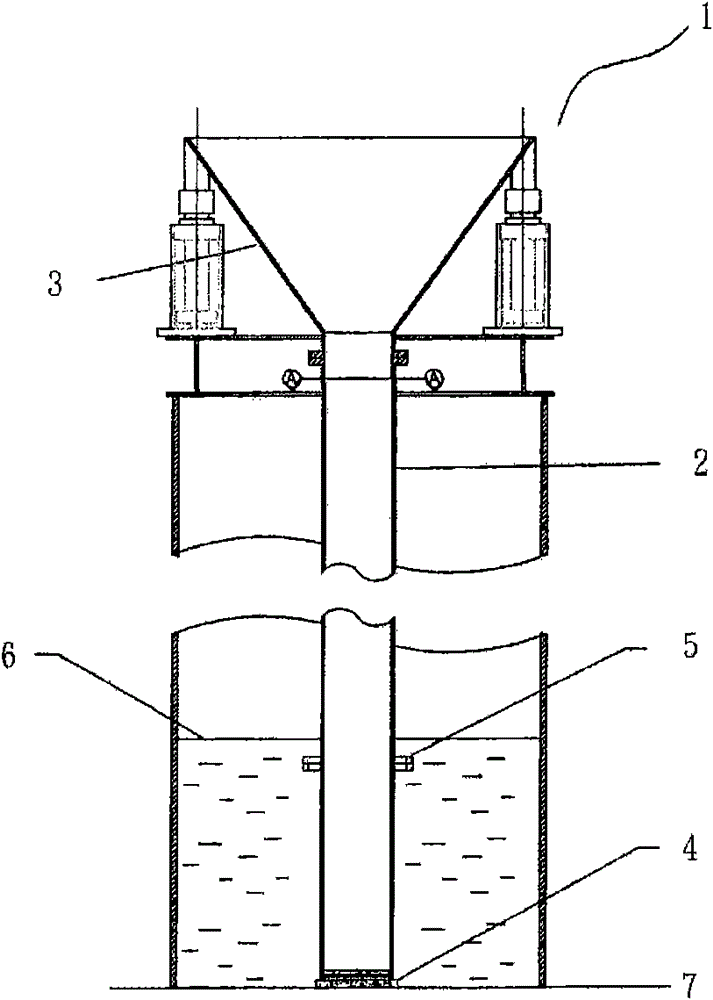

[0034] see figure 1 , the figure shows the concrete pouring equipment 1 of the present invention, which includes: a conduit 2, a funnel-shaped pouring device 3 connected to the upper end of the conduit, and a nozzle sealing device 4 arranged at the lower end of the conduit.

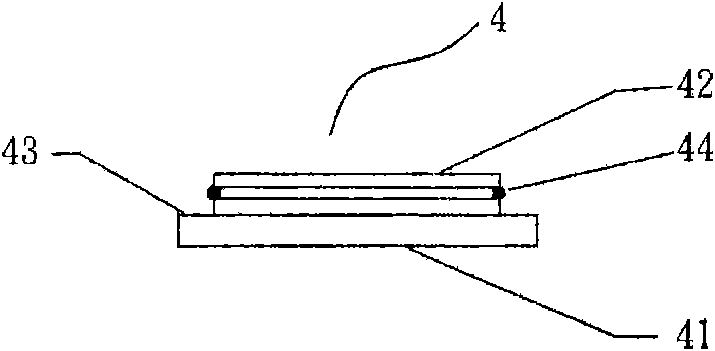

[0035] figure 2Shown is the orifice closure 4 at the lower end of the conduit 2 . As can be seen from the figure, the spout closure device 4 comprises an upper part 42 and a lower part 41 . Both the upper part and the lower part are in the shape of a short cylinder and the two parts are concentric. The diameter of the upper part 42 is smaller than that of the lower part 41 . Since the diameter of the lower part 41 is greater than that of the upper part 42 , the lower part 41 has an annular boss 43 relative to the upper part, and the boss is used to close the lower nozzle of the conduit 2 . In other words, the diameter difference between the upper and lower parts is at least equal to or greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com