Measuring device of pouring pile concrete surface

A technology of concrete surface and cast-in-place piles, which is applied in construction, foundation structure tests, foundation structure engineering, etc., can solve the problems of large access, increased mud weight, waste, etc., to achieve scientific and reasonable structure, control material waste, and safe use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

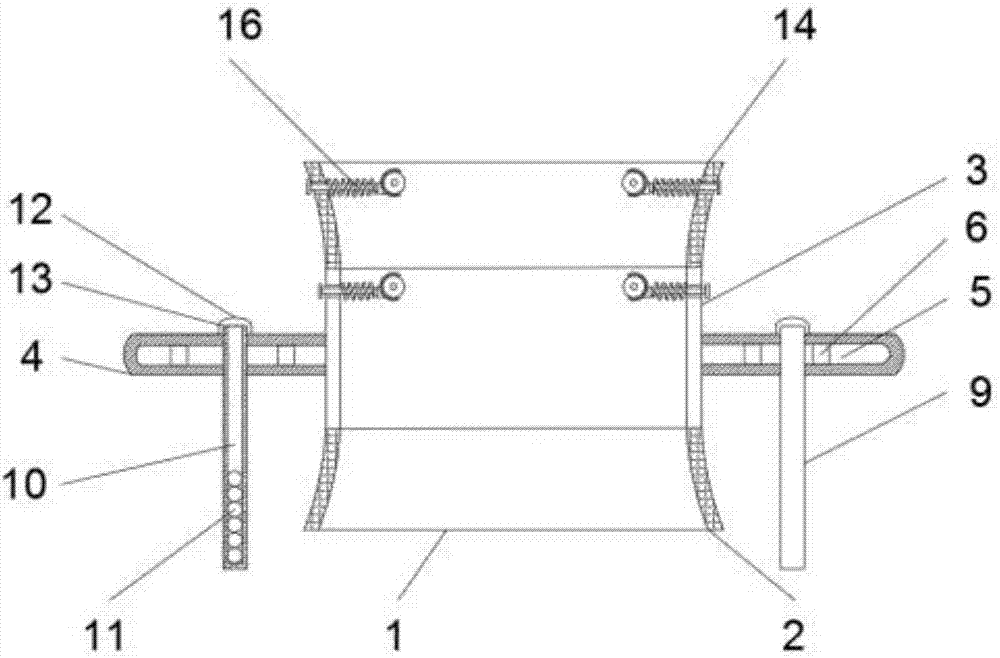

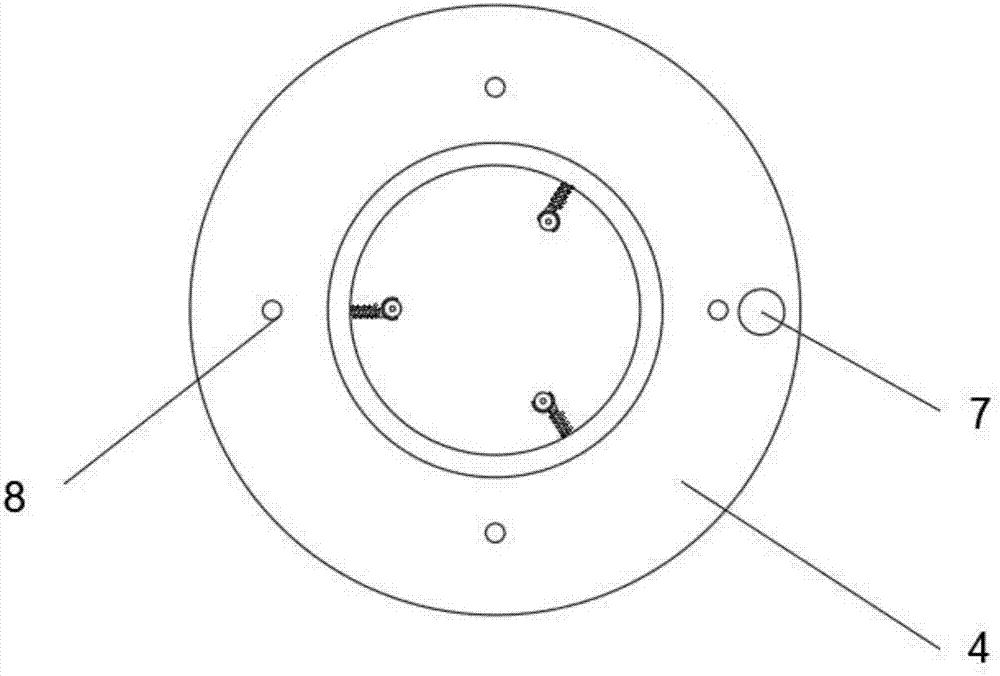

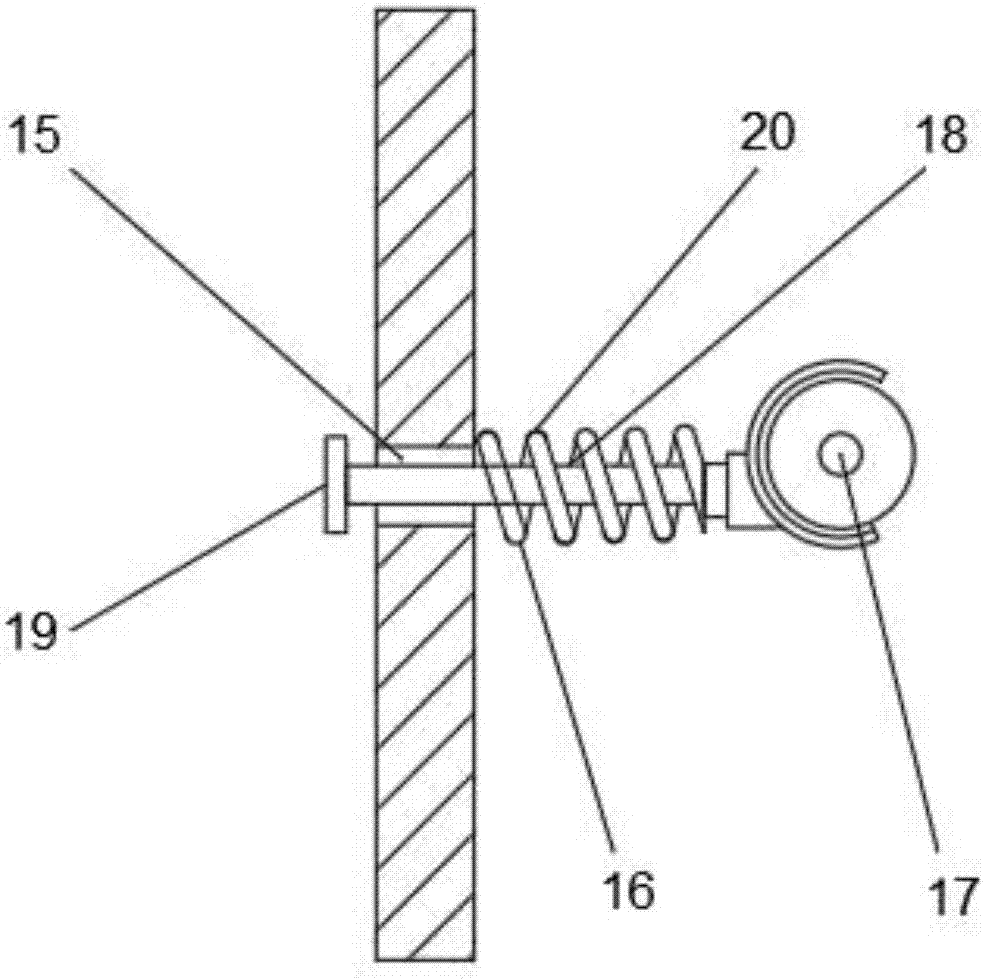

[0021] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a concrete surface measuring device for cast-in-situ piles, including a measuring device body 1, a lower sleeve 2, a middle sleeve 3, a floating plate 4, a cavity 5, a column 6, a measuring device Rope hole 7, first through hole 8, metal rod 9, blind hole 10, shot ball 11, end cap 12, threaded hole 13, upper sleeve 14, second through hole 15, guide 16, universal wheel 17, connecting Rod 18, baffle plate 19, spring 20, conduit 21, measuring rope 22, tension sensor 23, runner 24, motor 25, base 26, telescopic rod 27, directional wheel 28, battery 29 and TD-CLF-L3 type controller 30. The lower part of the measuring instrument body 1 is provided with a lower sleeve 2, the top surface of the lower sleeve 2 is provided with a middle sleeve 3, the outer side of the middle sleeve 3 is sleeved with a floating plate 4, and the inside of the floating plate 4 is provided with a cavity 5, A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com