A hollow self-expanding bottom anchor bolt and its installation method

An installation method and self-expanding technology, which can be used in the installation of bolts, earthwork drilling, sheet pile walls, etc., can solve problems such as poor bottom expansion effect, and achieve high reliability, good bottom expansion effect, and improved bottom expansion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

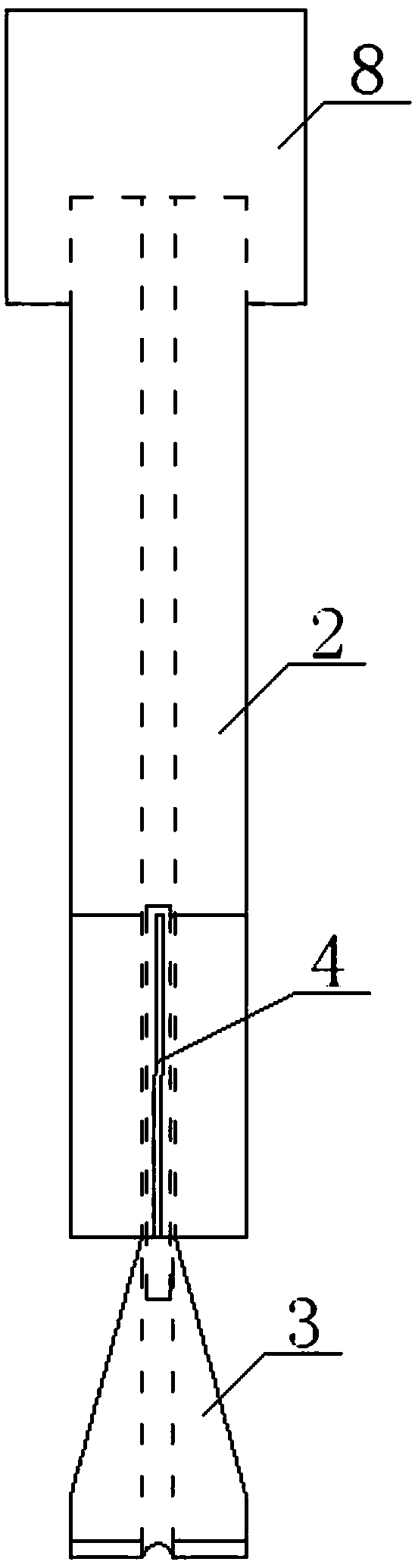

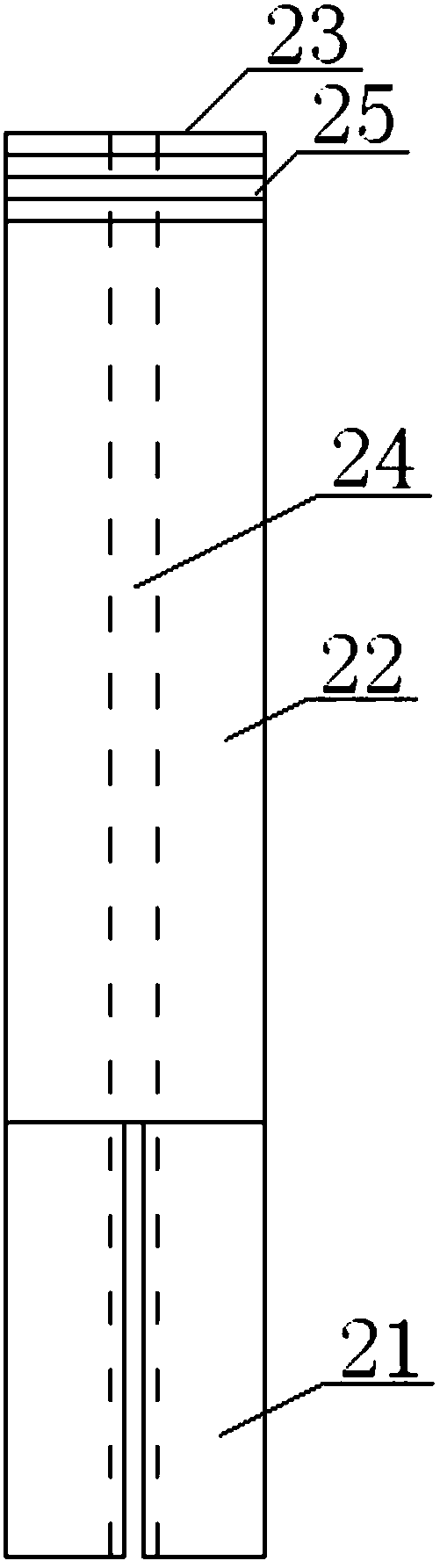

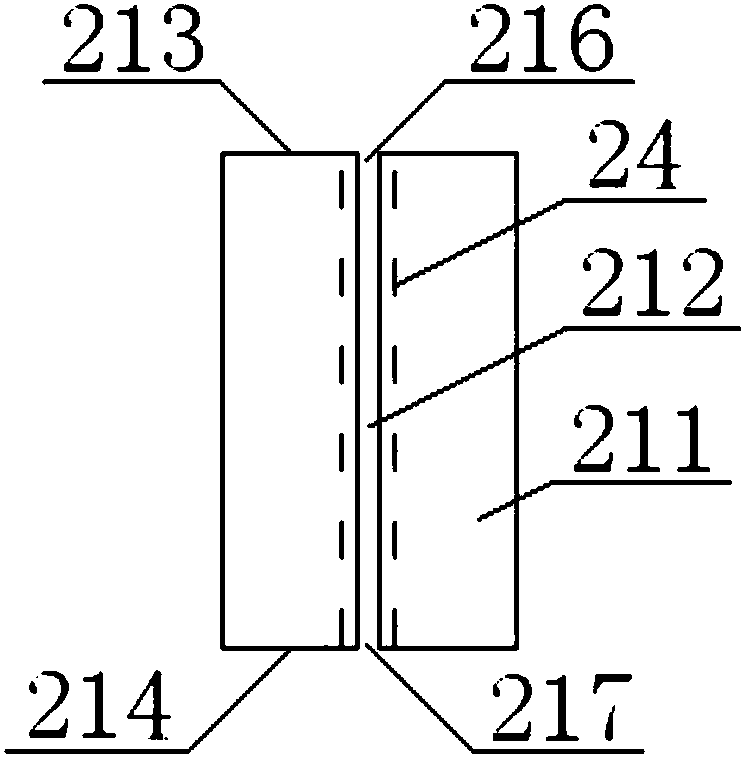

[0084] see Figure 1 to Figure 9 , a hollow self-expanding bottom anchor bolt, including a rod body 2, a wedge 3, and a liner pipe 4; the rod body 2 includes a bottom end 21, an intermediate rod 22, and an exposed end 23 connected in sequence; Rod inner hole 24, one end of the rod inner hole 24 extends to the end face of the exposed end 23, the other end of the rod inner hole 24 extends to the end face of the bottom end 21, the bottom end 21 includes a cutter head 211 and a slit 212, the number of the cutter head 211 is at least two, the cutter head 211 includes an upper end 213, a lower end 214, and an outer peripheral surface 215, the number of the slits 212 is equal to the number of the cutter heads 211, and the slits 212 are located at two adjacent Between two cutter heads 211, the slit 212 includes a first end 216, a second end 217, a third end 218, and a fourth end 219, the first end 216 extends to the end surface of the upper end 213, and the second end 217 extends On ...

Embodiment 2

[0089] Basic content is the same as embodiment 1, the difference is:

[0090] In terms of structure: the wedge head 31 is a regular pyramid structure. The wedge head 31 includes a wedge top 35 and a side edge 38. The wedge top 35 is in contact with the lower end 214. position, the taper angle 36 of the wedge head 31 is less than twice the friction angle between the two materials of the rod body 2 and the wedge block 3;

[0091] In step a: when the side edge 38 is located at the position facing the slit 212, the wedge top 35 is in contact with the lower end 214, and the outer peripheral surface of the other end of the lining pipe 4 is connected to the inner peripheral surface of the inner hole 24 of the rod, the insertion is stopped .

Embodiment 3

[0093] Basic content is the same as embodiment 1, the difference is:

[0094] In terms of structure: the wedge head 31 is a wedge structure, the wedge head 31 includes a wedge top 35 and a wedge surface 39, the wedge top 35 is in contact with the lower end 214, and the wedge surface 39 is located at a position facing the slit 212 , the taper angle 36 of the wedge head 31 is less than twice the friction angle between the two materials of the rod body 2 and the wedge block 3;

[0095] In step a: when the wedge surface 39 is located at the position facing the slit 212, the wedge top 35 is in contact with the lower end 214, and the outer peripheral surface of the other end of the lining pipe 4 is connected to the inner peripheral surface of the inner hole 24 of the rod, the insertion is stopped .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com