Gypsum slurry stirring and perfusion device

A technology of gypsum slurry and stirring rods, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., which can solve the problems of cumbersome steps for gypsum liquid, time-consuming, and insufficient filling of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

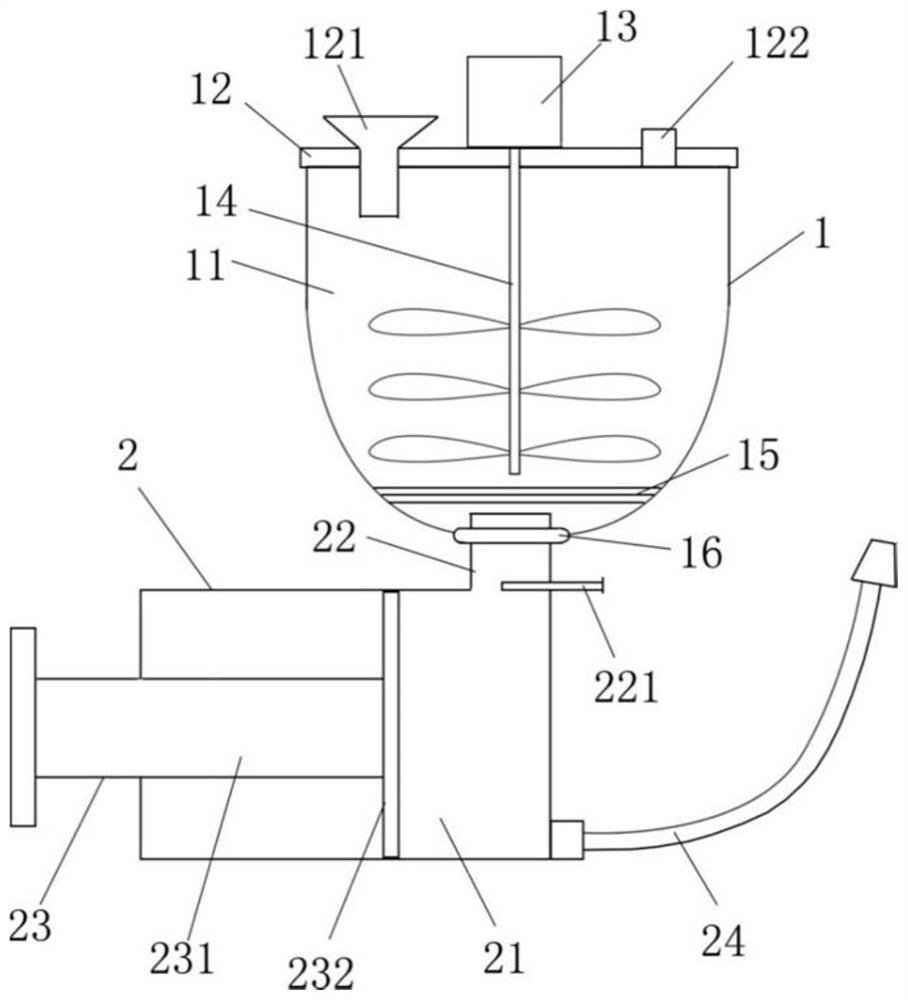

[0025] Such as figure 1 As shown, this embodiment provides a gypsum slurry stirring and pouring device, including a stirring module 1 and a pouring module 2 connected up and down.

[0026] The stirring module 1 includes a stirring container 11 , a cover 12 and a stirring mechanism. The stirring container 11 is a bottle with an open upper end, and the inner cavity at the bottom is an arc-shaped surface. The cover body 12 is mounted on the opening at the upper end of the stirring container 11 through a buckle structure. The stirring mechanism includes a motor 13 and a stirring rod 14 . An installation hole is provided at the center of the cover body 12, the motor 13 is installed above the installation hole, and the shaft coupling of the motor 13 passes through the installation hole. The stirring rod 14 comprises a connecting rod and a stirring blade. The upper end of the connecting rod is connected with the shaft coupling, and the whole connecting rod is located inside the s...

Embodiment 2

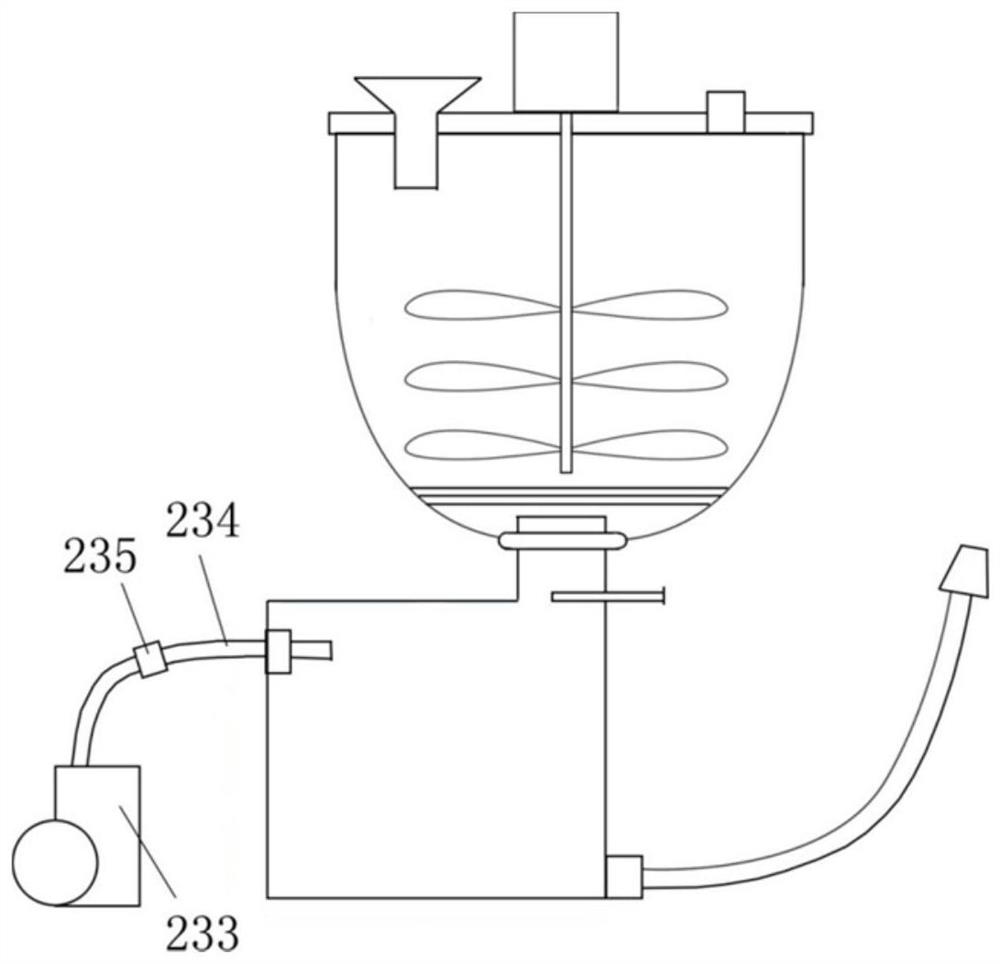

[0034] Most of the structures and principles of this embodiment are the same as those of Embodiment 1. The difference is that the pressurizing mechanism 23 uses an air pump 233 and an air intake pipe 234 . The air inlet pipe 234 is connected to the upper left end of the perfusion container 21 , and a constant pressure valve 235 is also provided on the air inlet pipe 234 . When in use, the air pump 233 and the constant pressure valve 235 are turned on, and air is injected into the perfusion module 2 , and then the air squeezes the gypsum liquid into the outlet conduit 24 to complete perfusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com