Repair tolerance analysis method based on computational simulation of constant speed transmission regulating system

A technology of regulating system and constant speed transmission, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as high cost, difficulty in identifying fault points, long time consumption, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

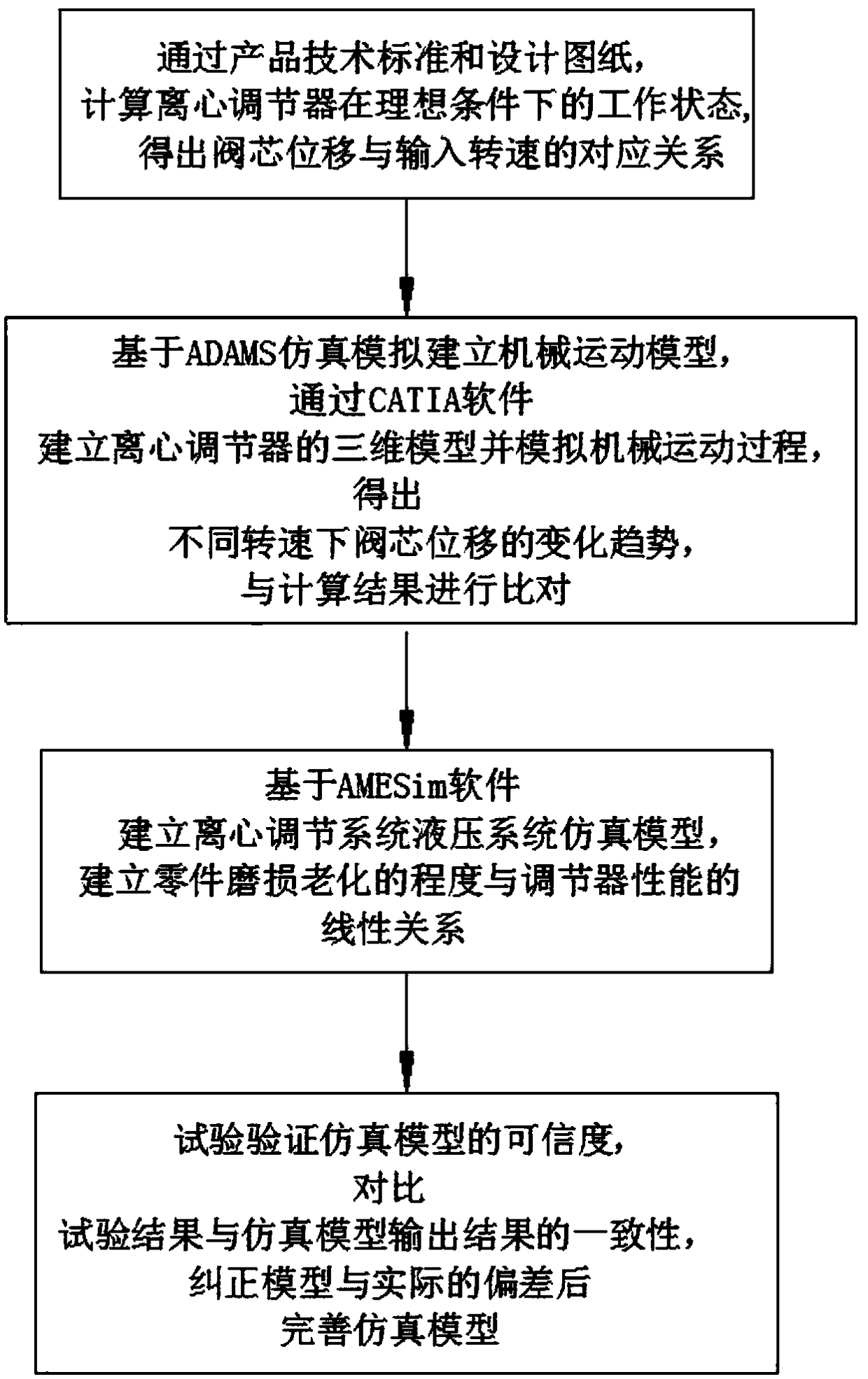

[0066] Such as figure 1 As shown, the repair tolerance analysis method based on the calculation and simulation of the constant speed transmission adjustment system includes:

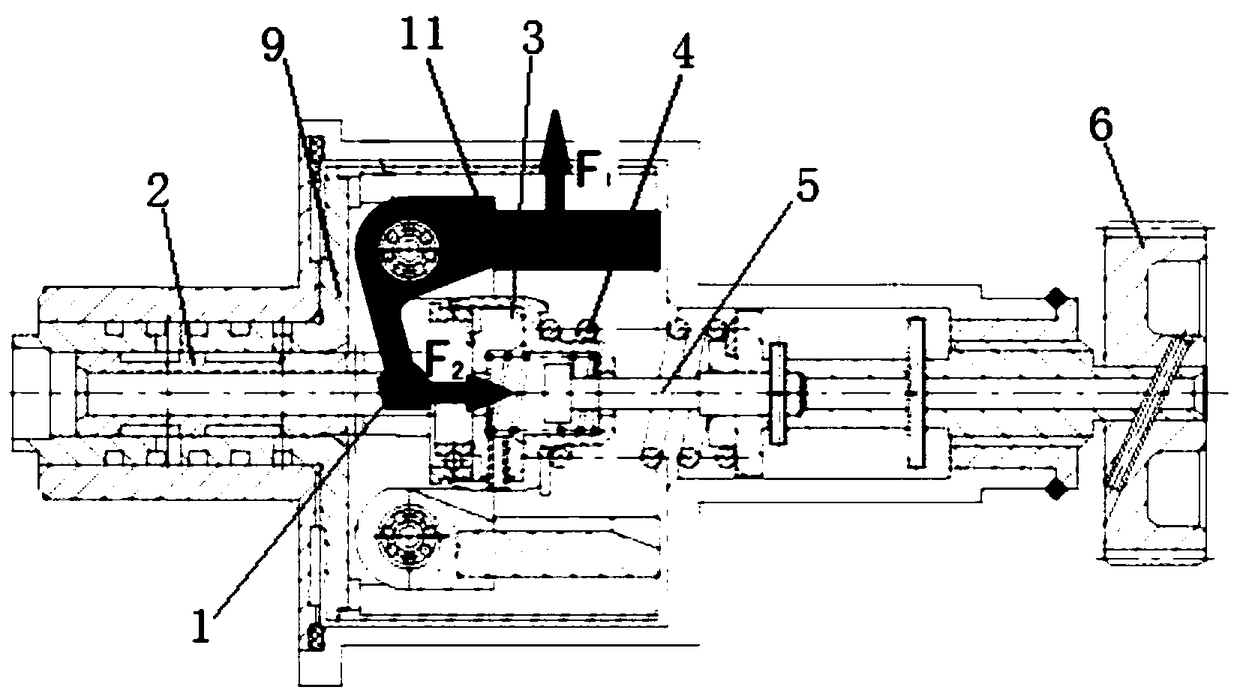

[0067] Step 1: Calculate the working state of the centrifugal regulator under ideal conditions through product technical standards and design drawings, and obtain the corresponding relationship between the displacement of the valve core 2 and the input speed;

[0068] Among them, the calculation of the working state of the centrifugal regulator under ideal conditions includes the following parameters;

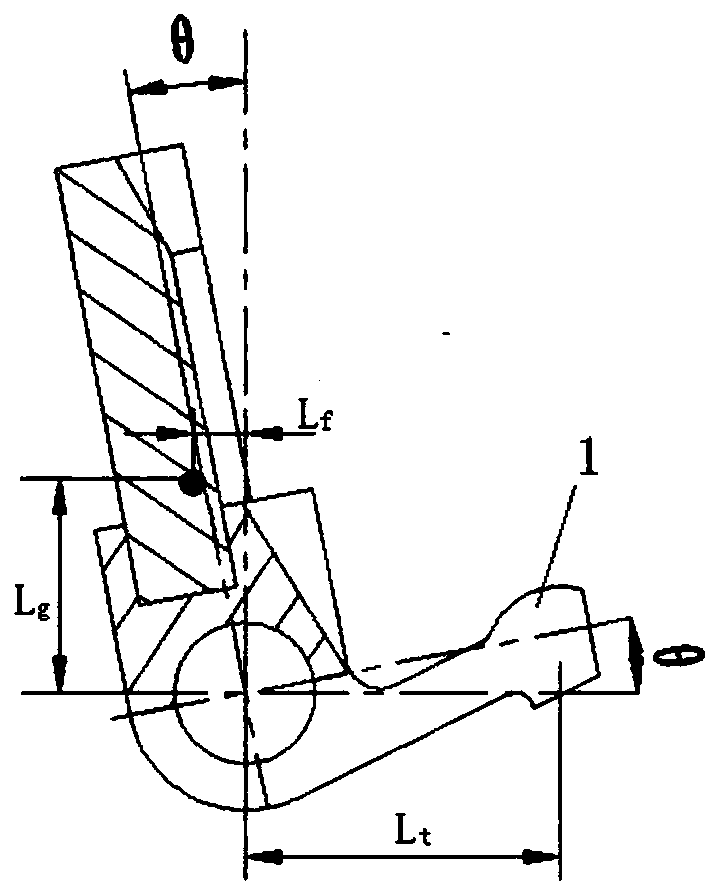

[0069] 11) Component parameters of the centrifugal block 11, the relationship between the distance from the contact position of the claw 1 on the centrifugal block seat and the valve core 2 to the rotating shaft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com