Microwave in-situ regenerative asphalt pavement maintenance vehicle and construction method

An asphalt pavement, recycling technology, applied in roads, roads, road repair and other directions, can solve the problems of the original pavement gradation change, the waste of asphalt layer heating energy, the leakage of liquefied gas, etc., to achieve a small temperature gradient between layers, good shielding Effect, effect of moderate heating depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

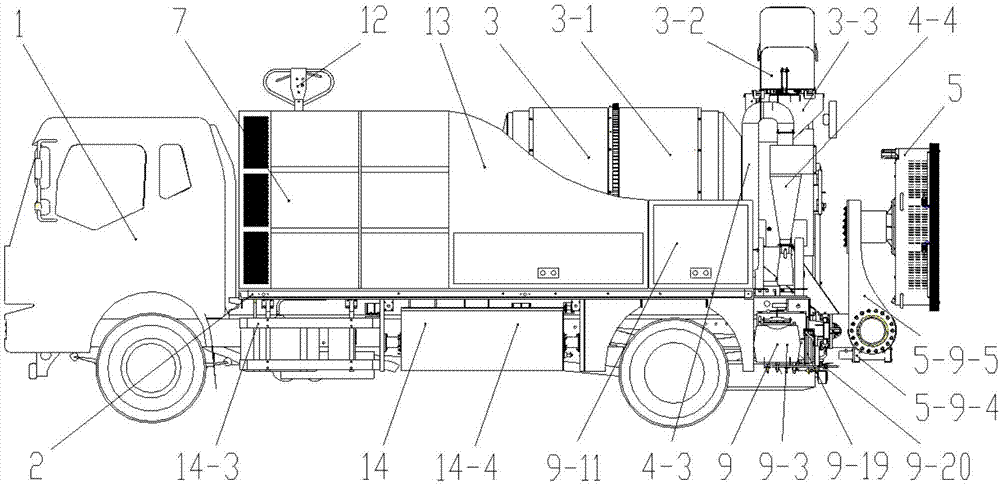

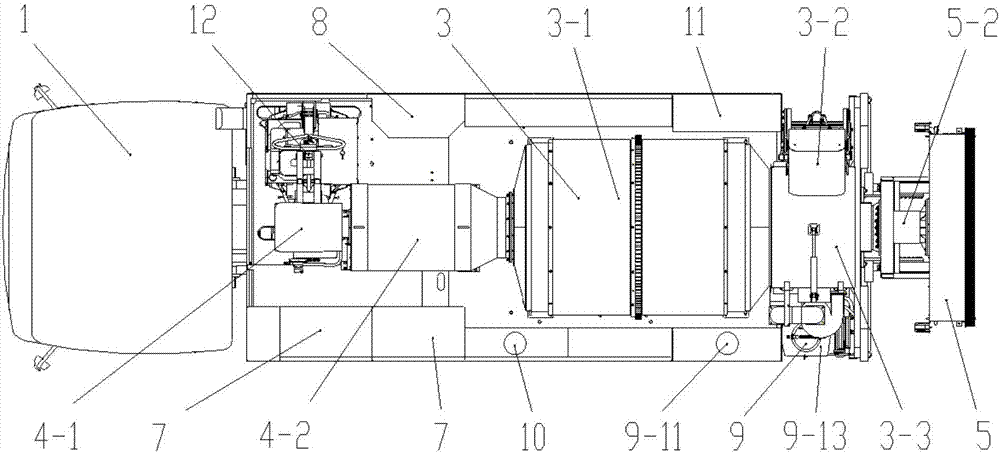

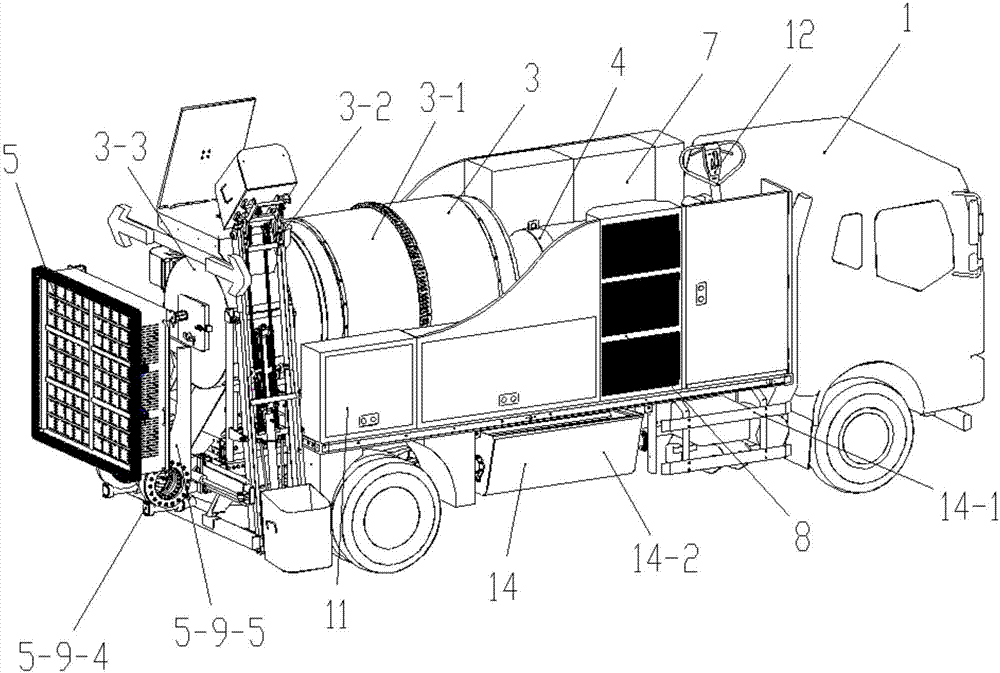

[0066] Such as Figure 1 to Figure 18 As shown, a microwave on-site regenerative asphalt pavement maintenance vehicle of the present invention includes a vehicle chassis 1, a vehicle frame 2, a drum silo 3, a heating system 4, a microwave heating wall system 5, a generator set 6, a transformer cabinet 7, Cooling system 8, emulsified asphalt system 9, hydraulic system 10, electrical system 11, roller equipment 12, upper enclosure 13, lower vehicle protection 14, vehicle frame 2 is fixed on the automobile chassis 1 through U-shaped screw, upper and lower connecting blocks, and thrust plate On the support beam, the drum silo 3 is located at the middle rear above the vehicle frame 2, and the front of the drum silo 3 is provided with a heating system 4, and the left and right sides of the heating system 4 are respectively a transformer cabinet 7, a cooling system 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com