Live-line work robot for repairing broken strand lead by protecting line

A technology of live work and protective wire, which is applied to the equipment for connecting/terminating cables, etc. It can solve the problems of inability to guarantee the conductivity of the wire and the cleanliness of the wire surface, so as to reduce the difficulty of positioning and improve the quality and effect of repair , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

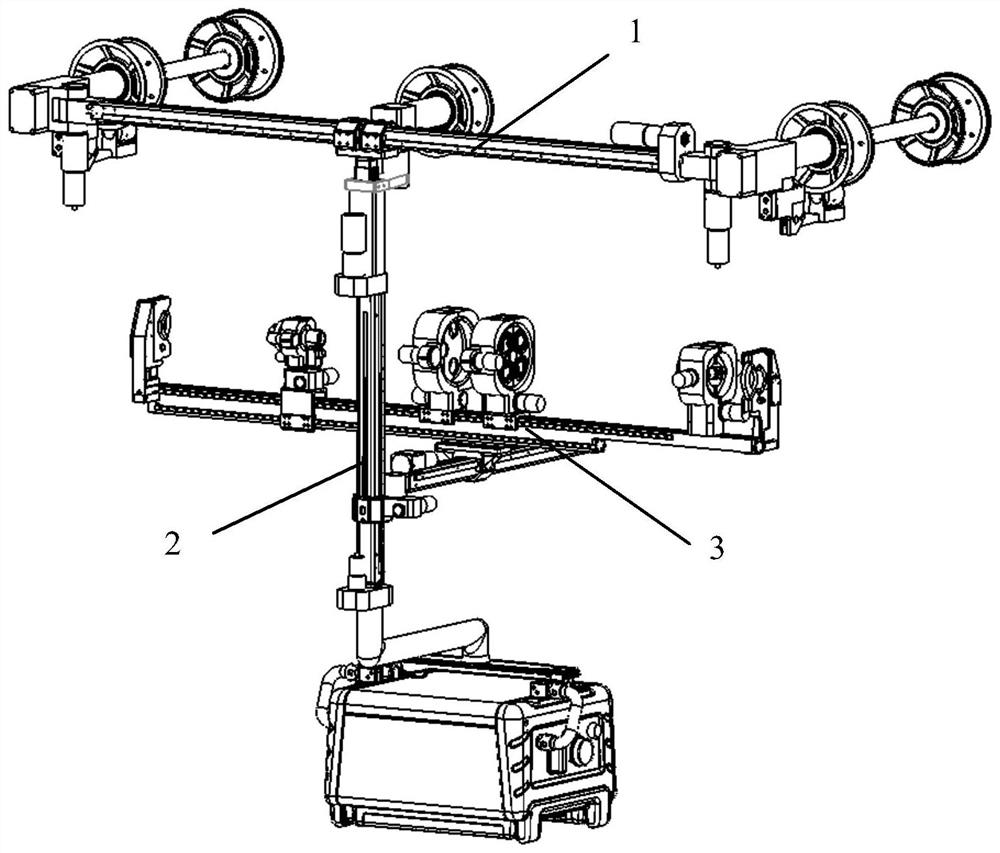

[0046] Such as figure 1 As shown, a live working robot for repairing a broken strand wire with a protective wire of the present invention includes a walking carrier 1, an obstacle avoidance mechanism 2 and a broken strand repair operation device 3, wherein the broken strand repair operation device 3 communicates with the broken strand repair operation device 3 through the obstacle avoidance mechanism 2. Said walking carrier 1 is connected. The walking carrier 1 described in the present invention adopts the existing technical means, such as the walking carrier disclosed in the authorized invention patent "a live working robot for overhead high-voltage transmission lines" (authorized announcement number CN109698475B).

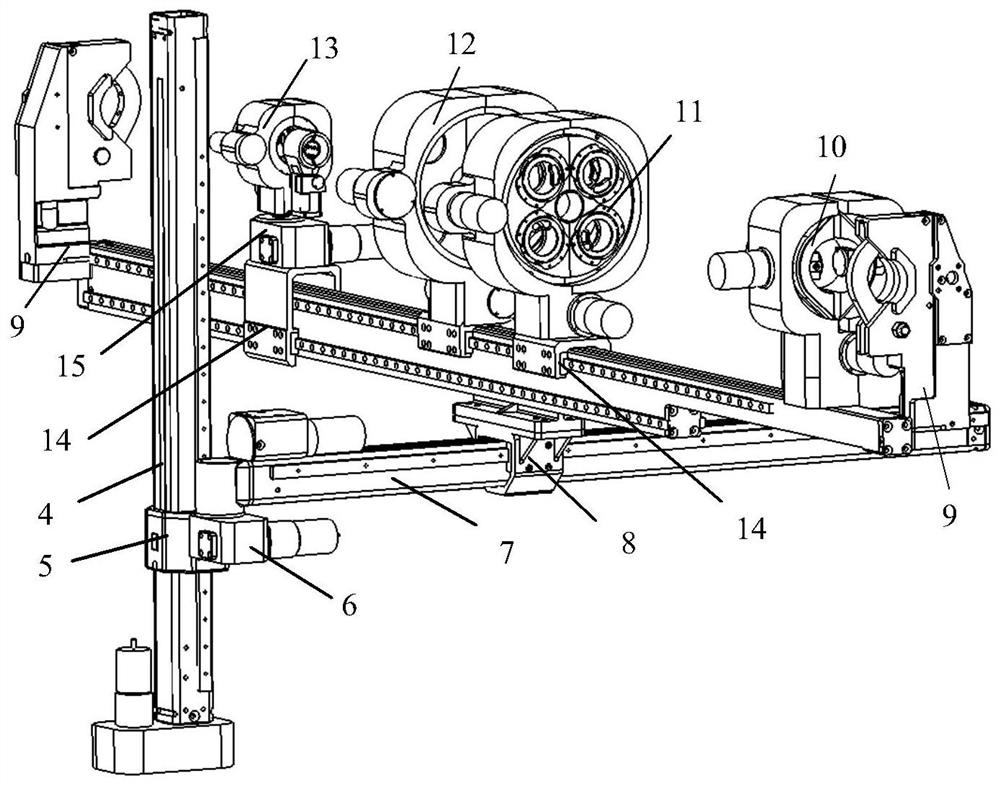

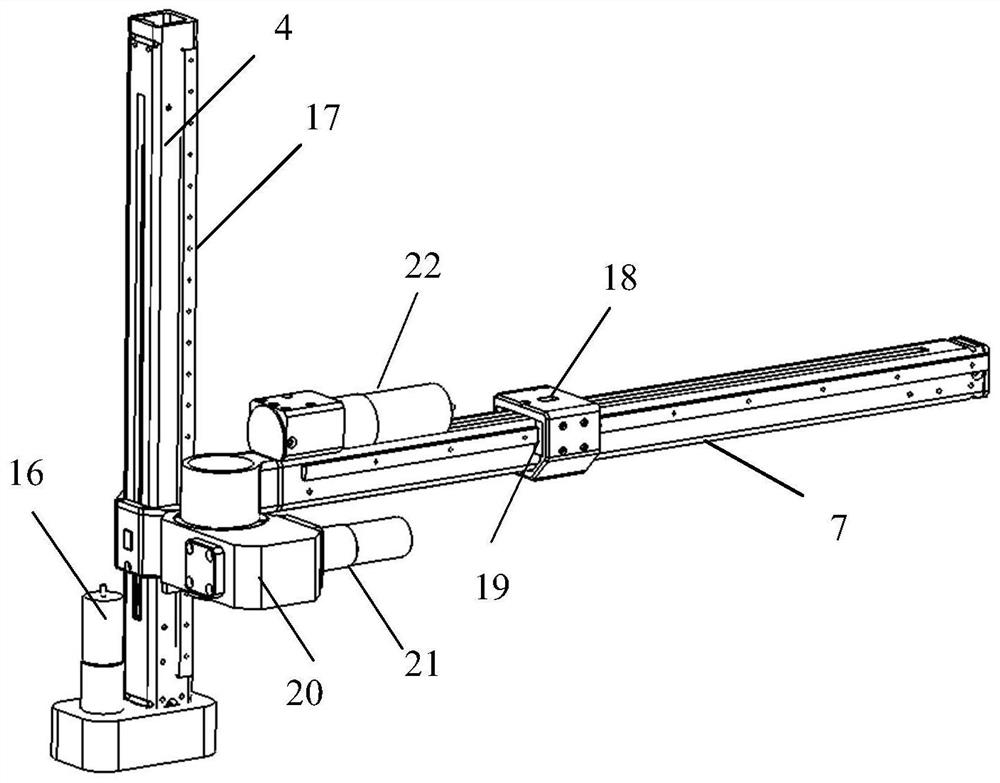

[0047] Such as figure 2 , 3 As shown, the obstacle avoidance mechanism 2 includes a vertical arm 4 and a cross arm 7, and the vertical arm 4 and the cross arm 7 are in a perpendicular relationship. The vertical arm 4 is a guide rail structure as a whole, on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com