Method for intelligently repairing insulating water tree of crosslinked polyethylene power cable

A cross-linked polyethylene and cable insulation technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of great differences in repair effects and achieve the effect of filling water tree defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

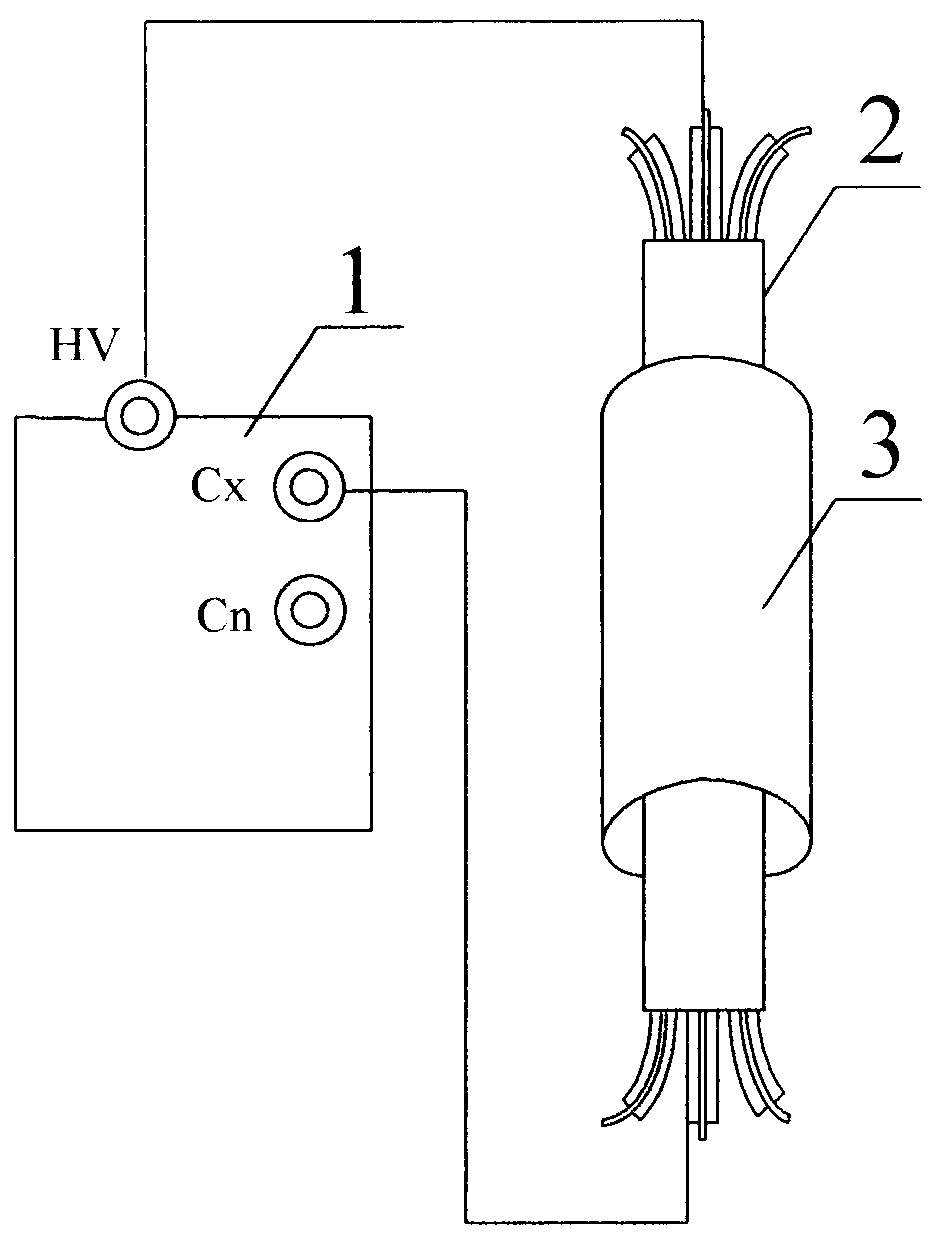

[0050] Test water tree aging cable insulation dielectric loss tangent tanδ 1 : Take a 5-meter water tree aging cable as a sample, connect the high-voltage HV connector of the dielectric loss tester to the cable conductor, connect the Cx connector to the metal shielding layer of the cable, and control the insulation temperature of the cable with a temperature controller. Choose 0.5U 0 The dielectric loss tangent tanδ of the cable insulation temperature at 20°C is obtained from the test voltage test 1 = 0.68%.

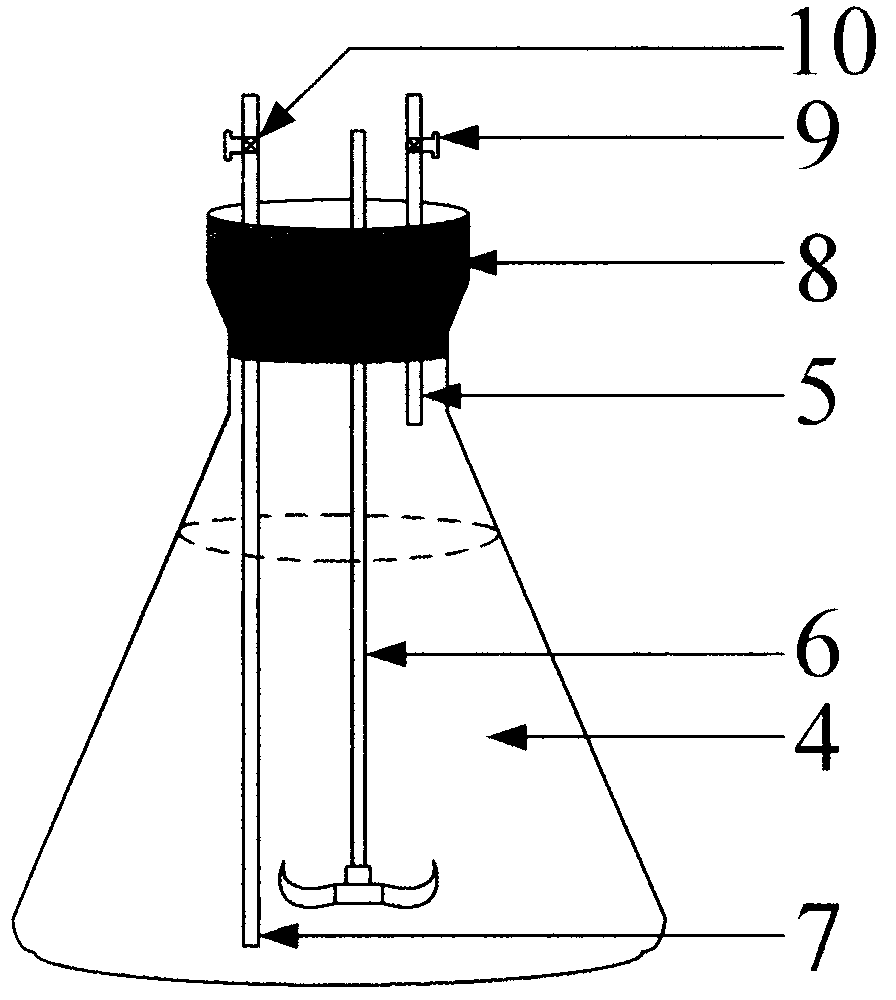

[0051] Test the dielectric loss tangent tanδ of the water tree aging cable after it is fully dried 2 : Cut out a 5-meter-long water tree aging cable, put it in a drying box, fill the cable conductor with dry air at 75°C to dry the cable insulation water tree, and test the cable insulation dielectric loss every 8 hours Angle tangent tanδ, where the cable insulation dielectric loss tangent test method: connect the high-voltage HV connector of the dielectric loss tester ...

Embodiment 2

[0068] Test water tree aging cable insulation dielectric loss tangent tanδ 1 : Take a 5-meter water tree aging cable as a sample, connect the high-voltage HV connector of the dielectric loss tester to the cable conductor, connect the Cx connector to the metal shielding layer of the cable, and control the insulation temperature of the cable with a temperature controller. Use U 0 The dielectric loss tangent tanδ of the cable insulation temperature at 20°C is obtained from the test voltage test 1 = 4.75%.

[0069] Test the dielectric loss tangent tanδ of the water tree aging cable after it is fully dried 2 : Cut out a 5-meter-long water tree aging cable, put it in a drying box, fill the cable conductor with dry air at 85°C to dry the cable insulation water tree, and test the cable insulation dielectric loss every 8 hours Angle tangent tanδ, where cable insulation dielectric loss tangent test method: connect the high-voltage HV connector of the dielectric loss tester to the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com