Online insulating property repairing method and device during operation of crosslinked polyethylene power cables

A technology of cross-linked polyethylene and power cables, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems that the injection pressure of the repair fluid cannot be kept constant, the time for cable power outage maintenance is increased, and the repair effect is weakened, so as to shorten the power outage Maintenance time, improvement of repair effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

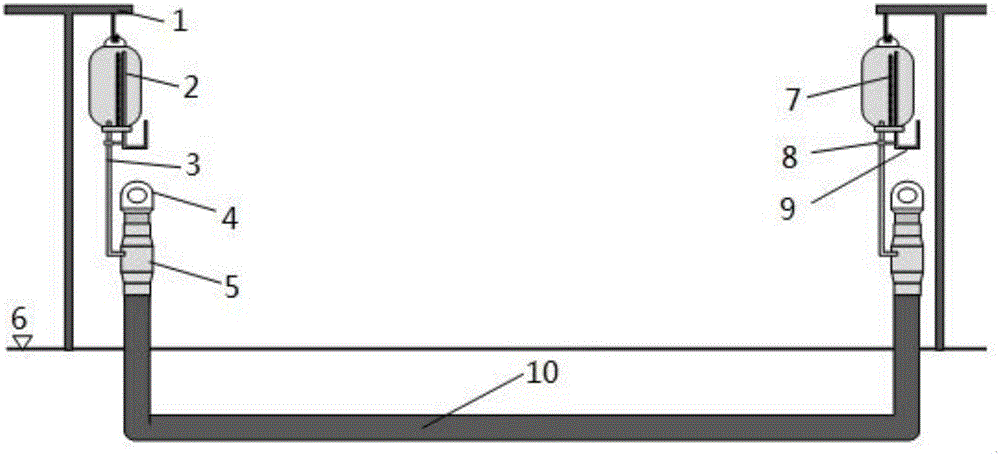

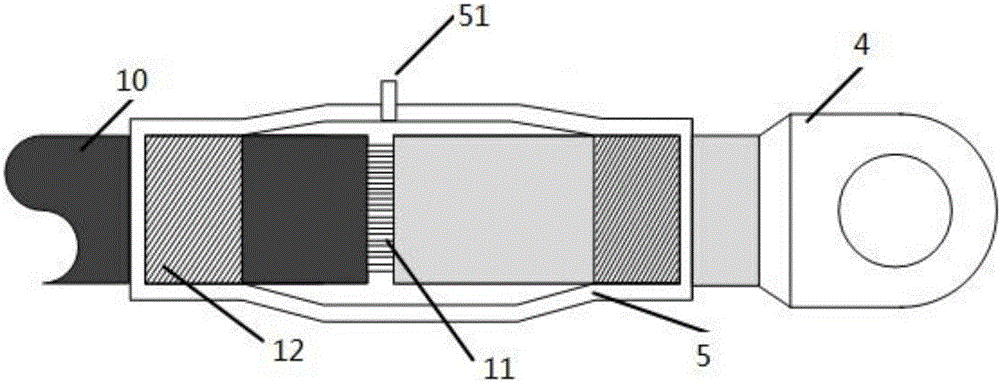

[0065] An on-line repair device for the insulation performance of a cross-linked polyethylene power cable during operation, comprising a repair liquid storage tank, a conduit and a cable terminal adapter, and the conduit is used to connect the repair liquid injection hole to the repair liquid storage tank liquid outlet connected; the adapter is provided with a restoration fluid injection hole communicating with its inner cavity, and the conduit is used to connect the restoration fluid injection hole with the outlet of the restoration fluid storage tank.

[0066] As an option, in the above-mentioned online repairing device, the adapter is in the shape of a cylinder and has an inner cavity through which both ends are connected, and the size of the inner cavity matches the outer diameter of the cable to be repaired, and can be sleeved on the terminal joint of the cable to be repaired place.

[0067] As an optional mode, fastening devices are provided at both ends of the adapter, ...

Embodiment 2

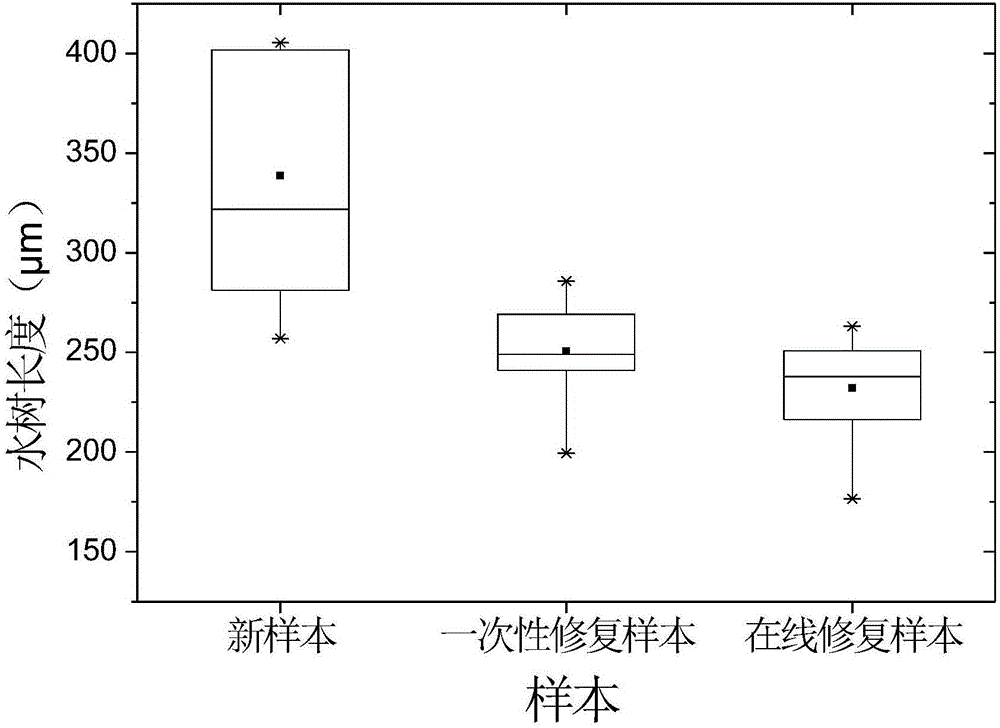

[0079] Example of online repair of cross-linked polyethylene

[0080] (1) power off

[0081] Cut off the power supply of the cable to be repaired, and take safety measures in accordance with the power cable operation regulations;

[0082] (2) Repair device connection

[0083] In the state of power failure, install a support frame made of insulating materials such as wood or plastic near the cable terminal, hang the repair liquid tank with a liquid level indicator and a pressure balance tube on the support frame, and then connect the copper nose of the cable terminal with the The gap between the insulation layers and the gap between the conductor connecting pipe and the insulation layer are exposed. Install the terminal adapter at the terminal joint at both ends of the cable. The repair fluid injection hole on the adapter is connected to the repair fluid storage tank through a hose. The storage tank is suspended above the location of the cable terminations;

[0084] (3) Prep...

Embodiment 3

[0102] Select any online repair device described in Example 1, first connect the two ends of the cable to be repaired to the repair device in the power-off state, so that the repair liquid can penetrate into the cable, and ensure that the repair liquid injection device can continue Fill the cable to be repaired with repair liquid, switch on and transmit power, and keep the repair liquid injected during the power-on process. After repairing for a period of time (2 months), turn off the power and remove the online repair device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com