Assembled high-voltage isolation switch conductive disc and installation method

A high-voltage isolating switch, conductive disc technology, applied in switchgear, electric switch, high-voltage air circuit breaker and other directions, can solve the problems of long maintenance cycle, prolong power failure time, burn out conductive rollers, etc., to reduce power failure maintenance time, The effect of high operational reliability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

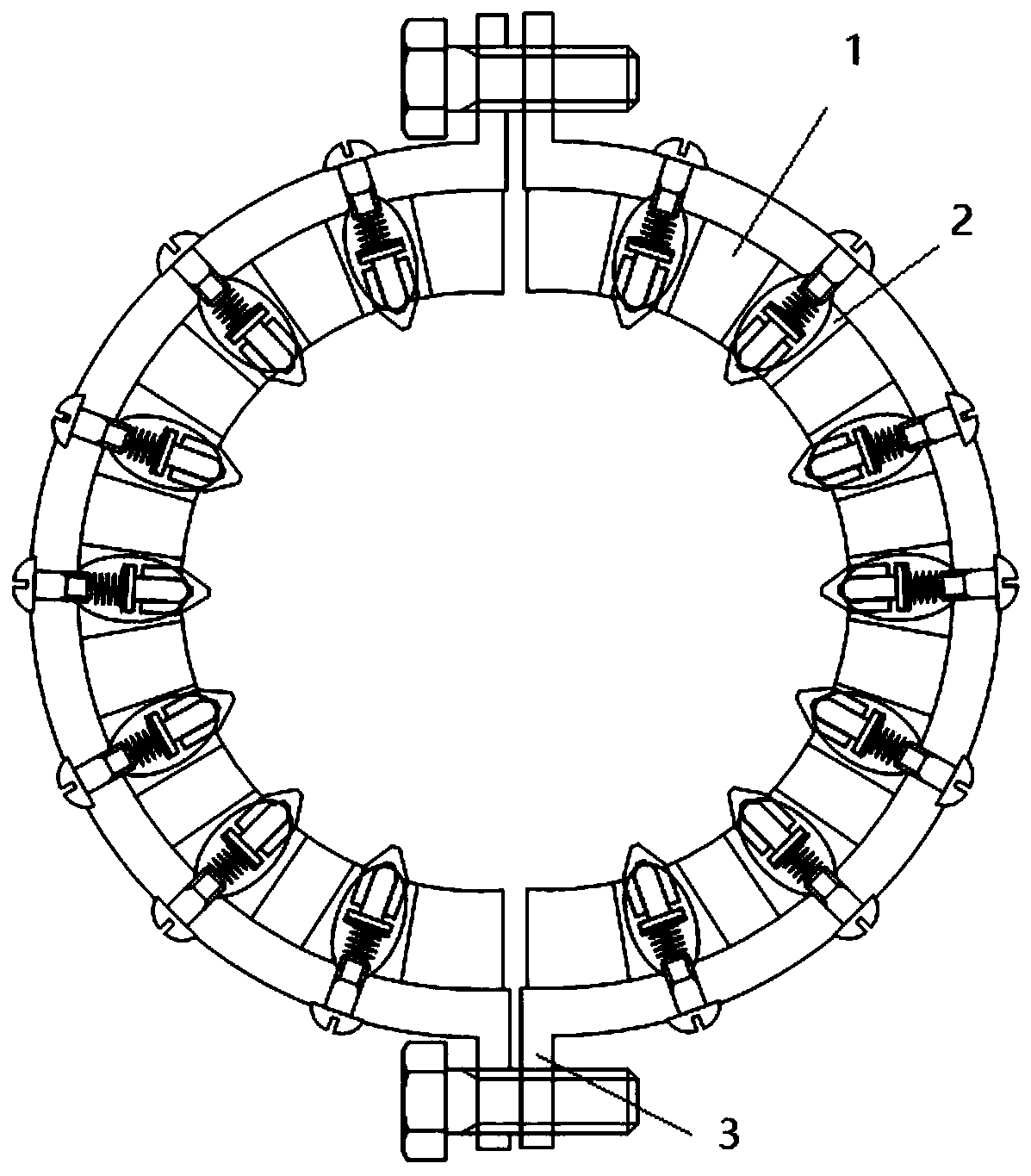

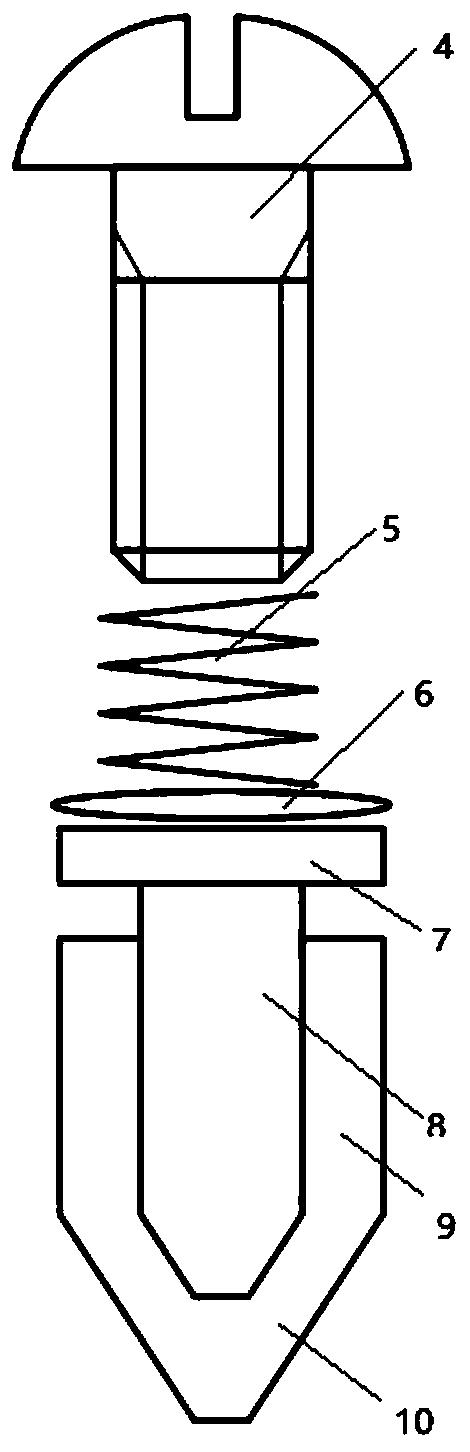

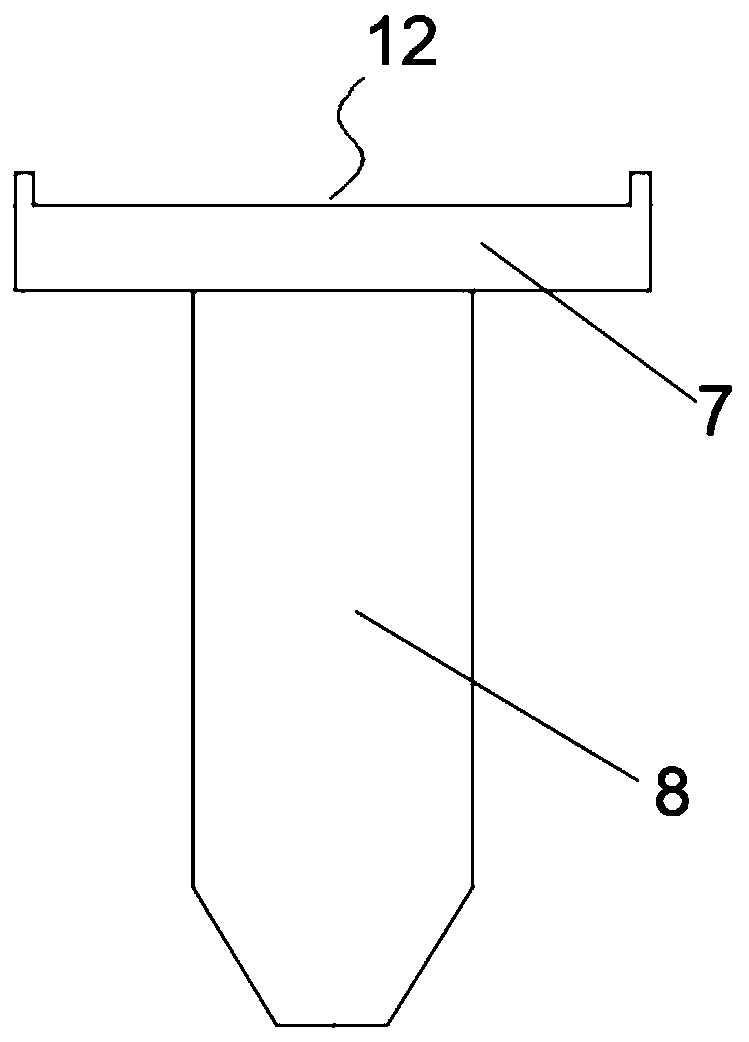

[0032] figure 1 It is a schematic diagram of the first structure of the present invention; figure 2 It is a structural schematic diagram of the conductive roller mechanism of the present invention; image 3 It is a top view of the adjusting bolt of the present invention; as shown in the figure; a conductive plate of an assembled high-voltage isolating switch, including two semi-disc mounting seats 1 that are used in conjunction with each other and can be embraced into a circular structure, and the semi-disc mounting seat 1 A plurality of installation holes 2 are arranged along the radial direction of the circumference, and a conductive roller mechanism is arranged in the installation hole 2; The guide seat used, the spring 5 arranged at the end of the guide seat, and the adjusting bolt 4 used to adjust the compression of the spring 5, the conductive plate of the assembled high-voltage isolating switch of this technical solution can be flexibly disassembled without hoisting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com