Portable carbon resistance welding device

A welding device and a portable technology, applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of reducing the convenience of welding devices, time-consuming and laborious operation, and the inconvenience of carrying welding tools, so as to reduce power outage maintenance time and save Working hours fee, the effect of protecting interests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

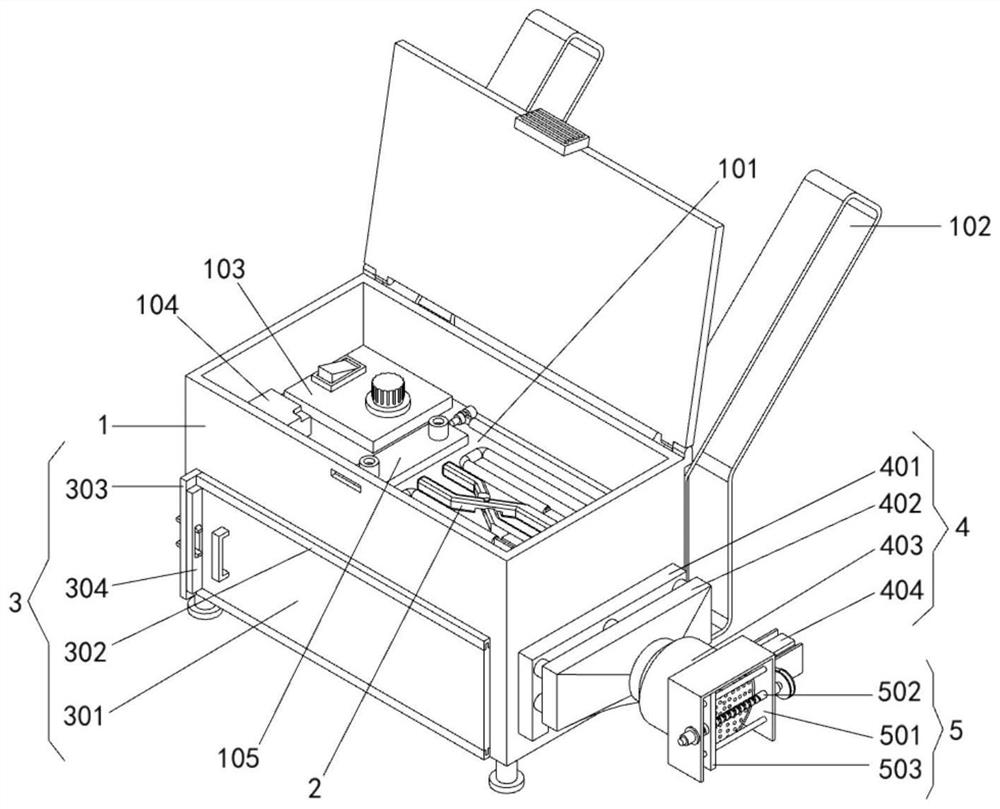

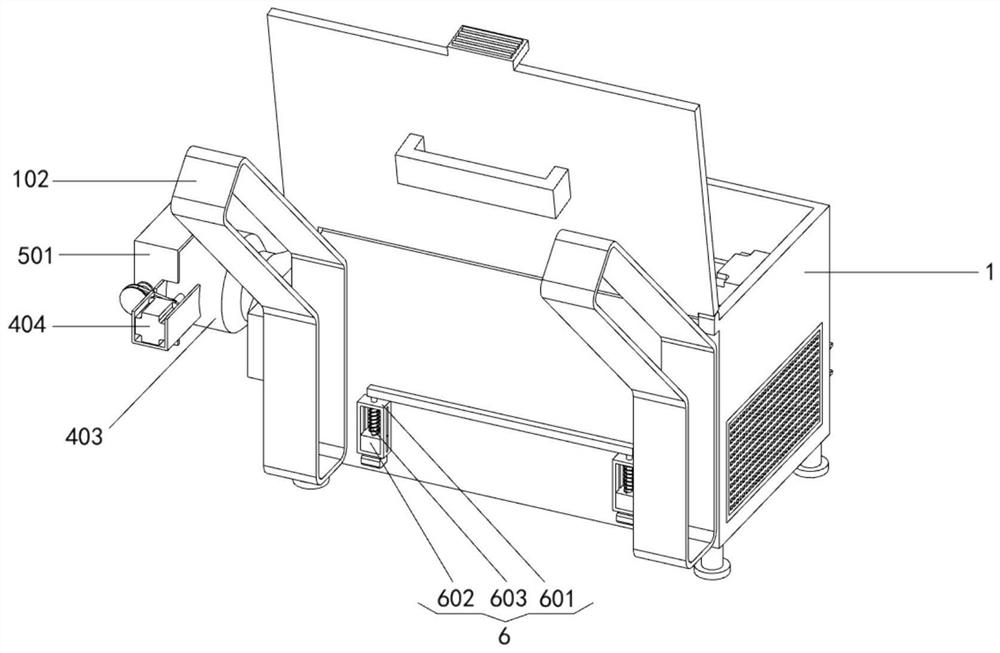

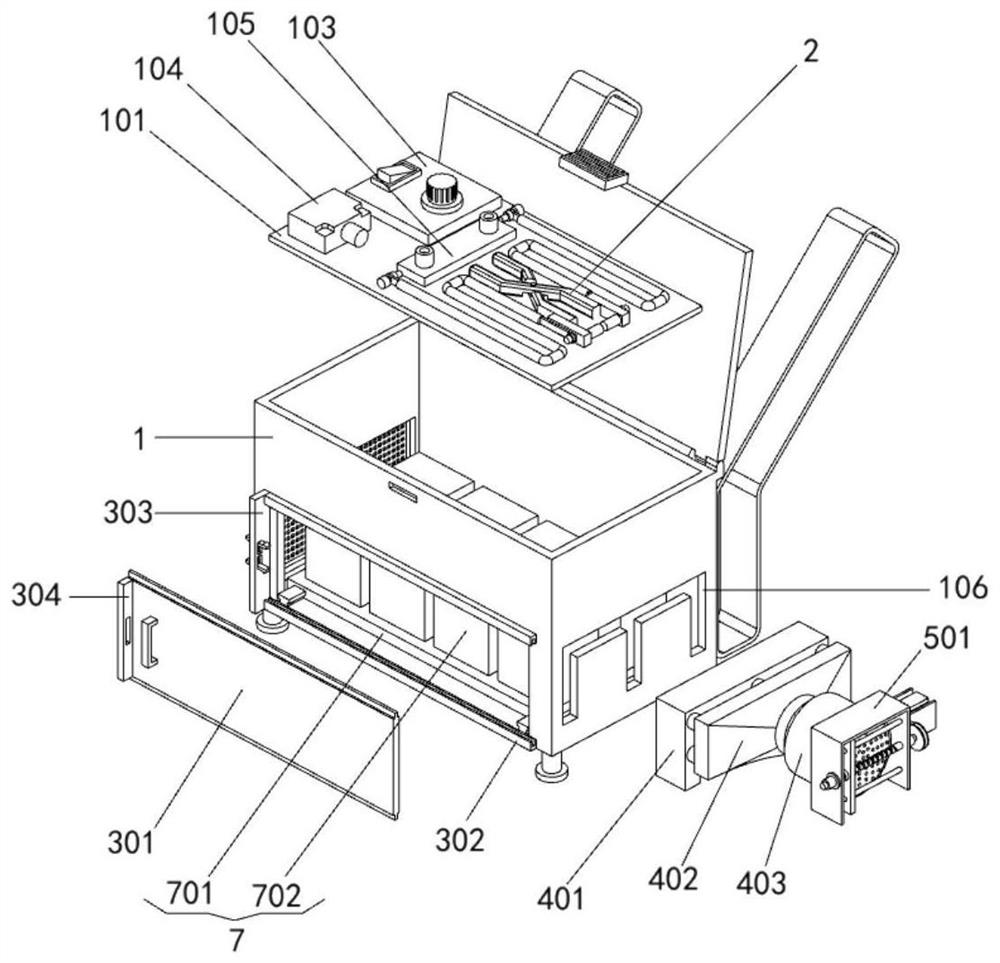

[0036] Example: Please refer to Figure 1 to Figure 10 :

[0037] The present invention proposes a portable carbon resistance welding device, comprising: a housing box 1; a rectangular opening is opened at the lower part of the front end of the housing box 1, and a shield assembly 3 is installed outside the rectangular opening on the front end of the housing box 1; The right end surface of the box body 1 is provided with an E-shaped port 106 for installing the blower cover A401, and the right end surface of the containing box body 1 is located at the E-shaped port 106. A blowing mechanism 4 is provided, and the right end of the blowing mechanism 4 is provided with a cleaning part 5. The rear end surface of the storage box 1 is equipped with a limiting part 6, and the inner bottom surface of the storage box 1 is equipped with a battery assembly 7, which is used to provide power for the hand-held welding piece 2; the inside of the storage box 1 is fixed with a support plate 101,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com