A plugging method for gas leakage of gis equipment with electricity and pressure

A technology for plugging leaks under pressure and gas leakage, which is applied to electrical components, switchgear settings, switchgear and other directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

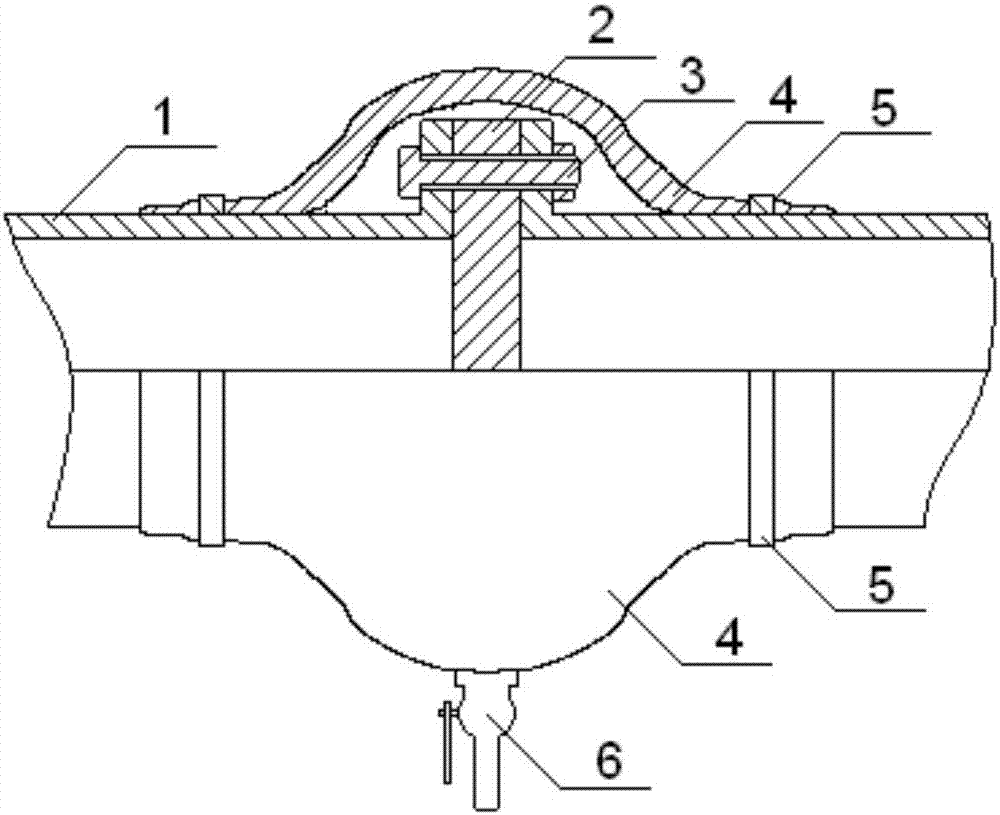

[0026] 1. There is sulfur hexafluoride gas leakage at the position of the A-phase flange of a 500kV outdoor GIS I. First, prepare a 2.5m-long Ω-shaped rubber strip 4 according to the diameter of the equipment, that is, an Ω-shaped neoprene strip. A small hole is opened in the middle position, and the shut-off valve 6, namely the ball valve, is fixed above the small hole of the Ω-shaped neoprene strip with acrylic adhesive, and the ball valve is opened.

[0027] 2. Remove dust and oil on both sides of the leakage flange of GIS equipment 1.

[0028] 3. Apply the acrylic adhesive to the straight positions of both ends of the Ω-shaped neoprene strip, and then wrap it circularly on both sides of the leakage flange of the GIS equipment 1.

[0029] 4. Use acrylic adhesive to bond the overlapping part of the Ω-shaped neoprene strip firmly.

[0030] 5. Use stainless steel cable ties to fix the two ends of the Ω-shaped neoprene strip on the GIS device 1 in a straight position.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com