Follow-up type high-efficiency water-stop and sand-hindrance precipitation complex system and its construction method

A composite system and water-stopping technology, which is applied in excavation, infrastructure engineering, special data processing applications, etc. Settlement, easy construction operation, large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

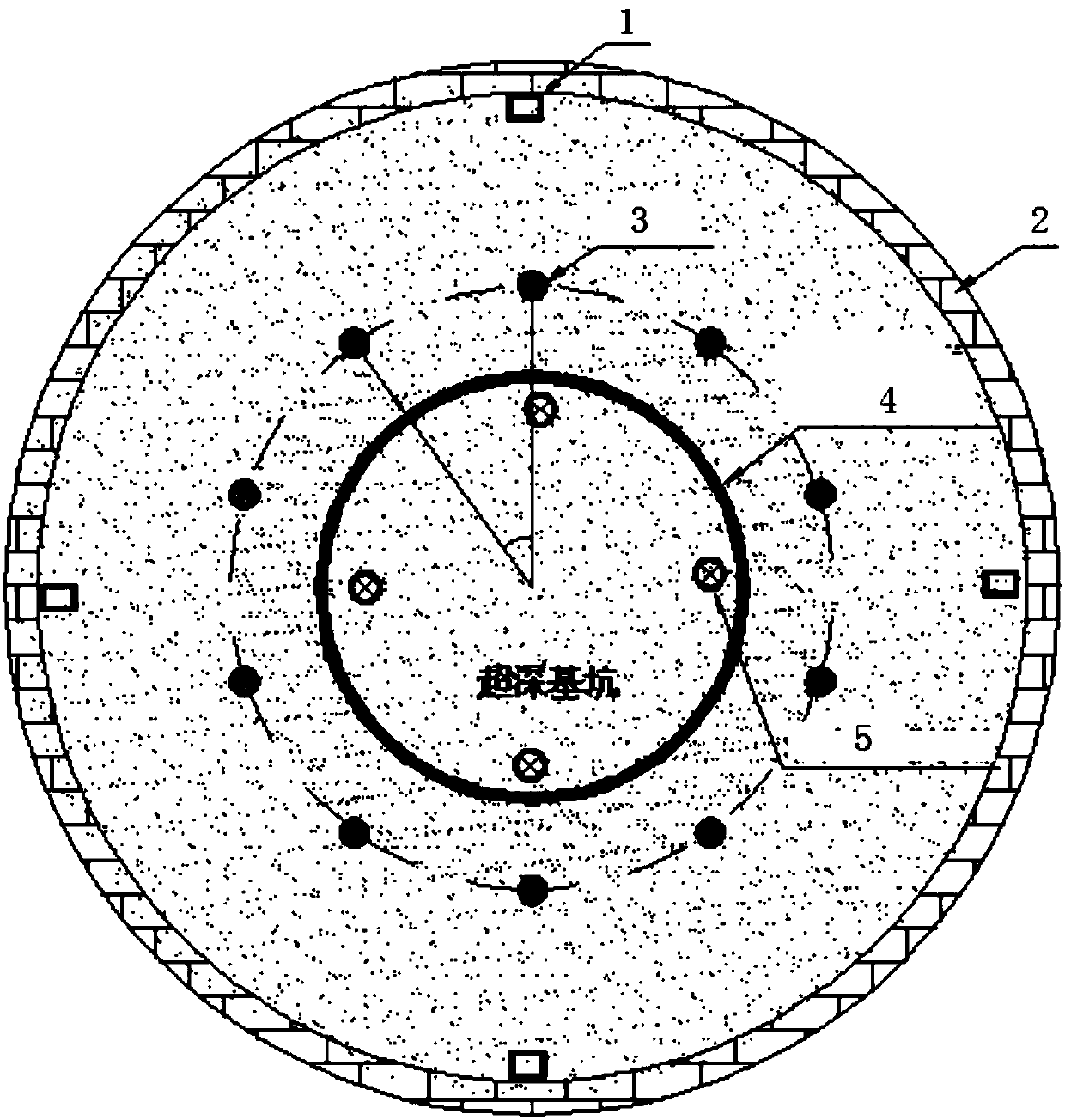

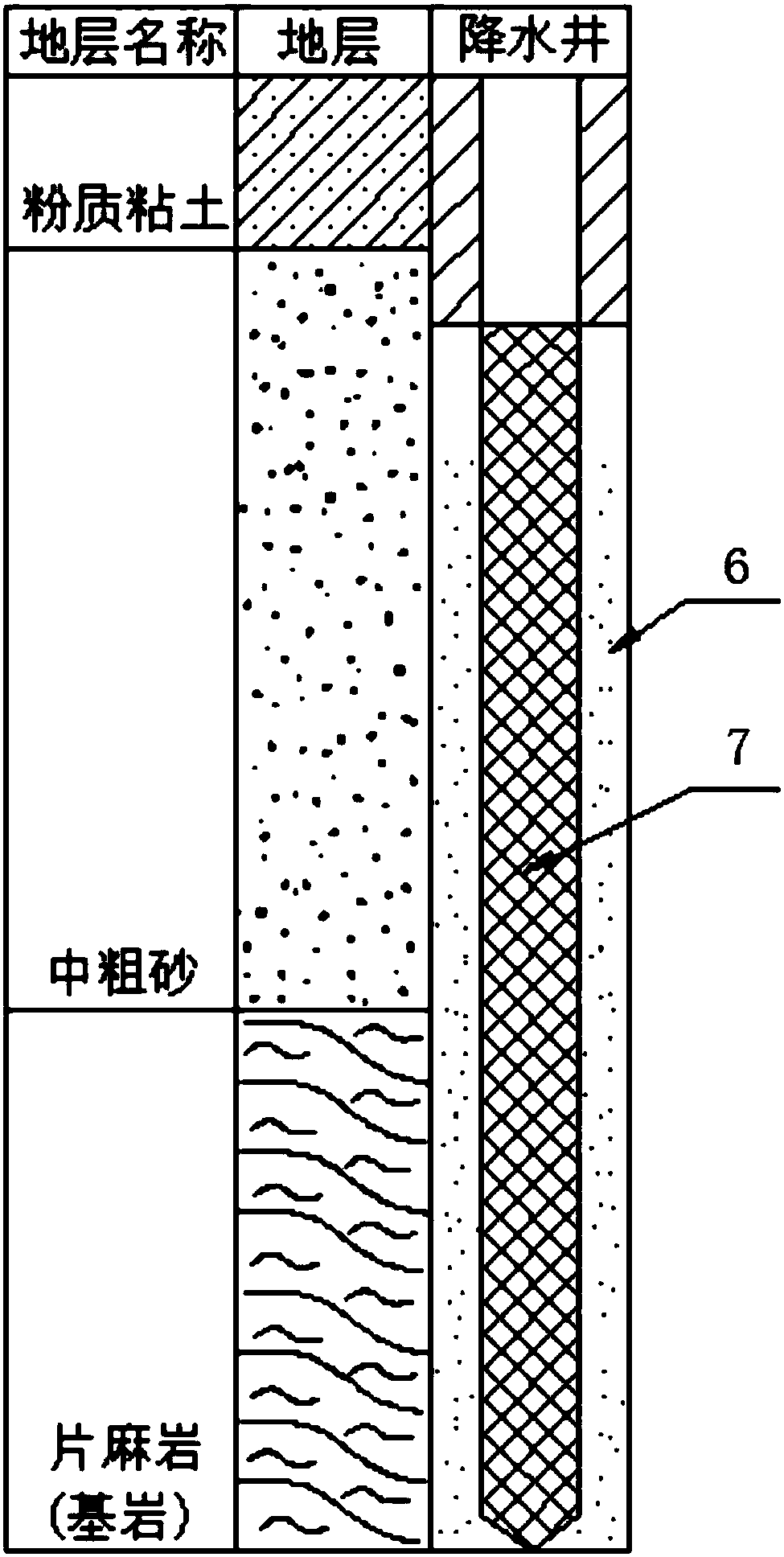

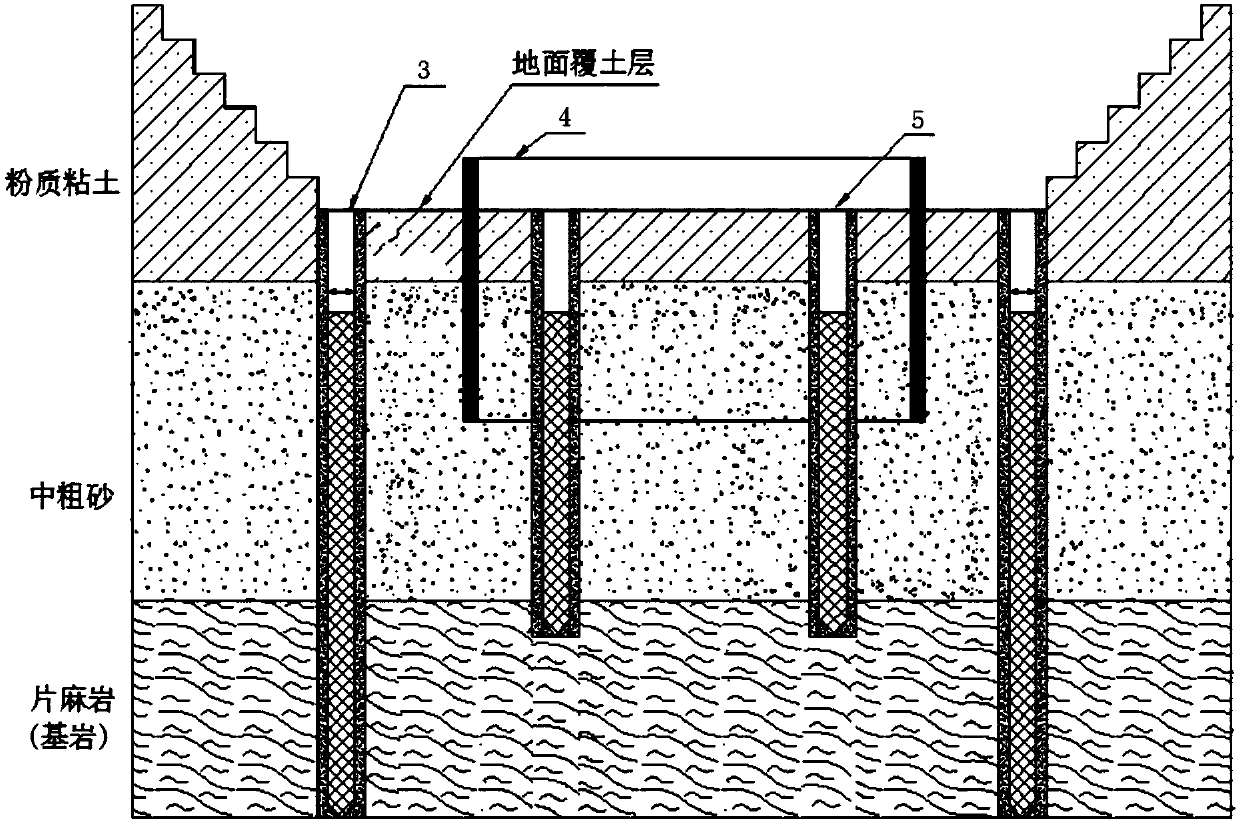

[0058] A follow-up high-efficiency water-stopping and sand-blocking precipitation composite system, such as Figure 1-3 As shown, it is used for the prevention and control of ultra-deep foundation pit dewatering and ground subsidence, including the dewatering well 3 located in the foundation pit. The well pipe of the dewatering well 3 is equipped with a percolation device 7 with the function of reducing resistance and collecting water. A submersible pump is provided to drain water to the external drainage ditch 2, a sand filter material layer 6 is set outside the well pipe of the dewatering well 3, a mobile follow-up water-stop curtain 4 is set in the foundation pit, and a settlement observation point is set on the outer edge of the foundation pit 1. An open seepage drainage well 5 is set on the inner side of the mobile follow-up water-stop curtain 4 . Wherein, the dewatering well 3 is annularly arranged on the outside of the movable follow-up water-stop curtain 4, the inner d...

Embodiment 2

[0060] A mobile follow-up high-efficiency water-stopping and sand-blocking precipitation compound system and its construction method are located in Hushan Town, Rizhao City. The ultra-deep foundation pit is a swirl pool under construction by Rizhao Iron and Steel Co., Ltd., which is inscribed by a circle with a diameter of 16.60m and a circle with a diameter of 12.925m. , The pool wall thickness is 1m.

[0061] According to the "Swirl Pool and Hot Rolling Workshop Supplementary Survey Report of Rizhao Iron and Steel Co., Ltd. - Geotechnical Engineering Survey Report", the hydrogeological conditions on which the tube well dewatering design is based are mainly reflected as follows:

[0062] (1) Stratum structure: the thickness of the Quaternary covering layer in the field is less than 25m, and each layer from top to bottom is Quaternary Holocene silty clay, fine-medium sand, silty silty clay, Pleistocene silty clay, medium Coarse sand, Proterozoic weathered granite gneiss.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Filter hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com