Stereo garage quick assembly framework

A three-dimensional garage, fast technology, applied in the direction of the building, building type, building, etc. where the car is parked, it can solve the problems of bolt slipping, easy to bite, long cycle, etc., and achieve the effect of fast assembly and strong splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

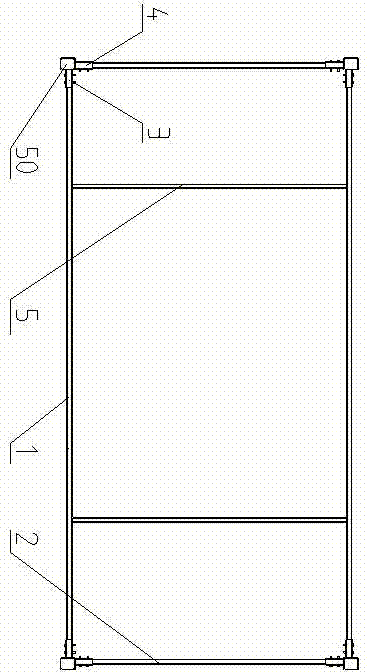

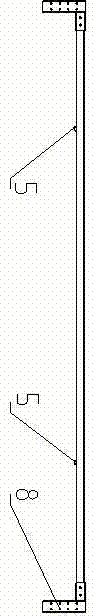

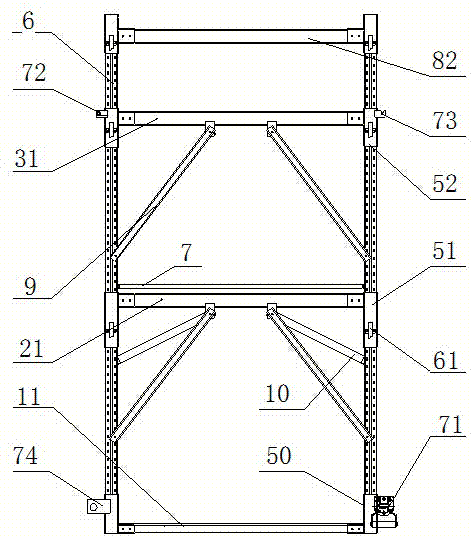

[0015] From figure 1 Front view of one-floor berth unit module of the present invention, figure 2 top view of image 3 It can be seen from the front view of a train depot unit that the present invention is a frame structure formed by connecting profiles, including a layer of berth unit modules, an intermediate berth unit module, a top berth unit module, a column 6, a quick positioning and locking module, a drive Device holder module 82 . The berth unit modules on the first floor, the middle floor, and the top floor are respectively equipped with longitudinal beam 1, beam 2, and tee modules. The tee modules on each floor are: the first floor tee module 50, the middle floor tee module 51, and the top floor tee module 52. The three-way module is composed of a long horizontal cylinder module 3 , a short horizontal cylinder module 4 and a vertical cylinder module 8 . The longitudinal beam 1 and the cross beam 2 are respectively inserted into the long horizontal cylinder module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com