Repair apparatus and repair method specific to high-altitude cable insulation layer aging

A technology for high-altitude cables and insulating layers, which is applied to equipment for dismantling/armored cables, and repairing equipment for insulating/armored cables, etc. Simple structure, low cost, and the effect of offsetting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

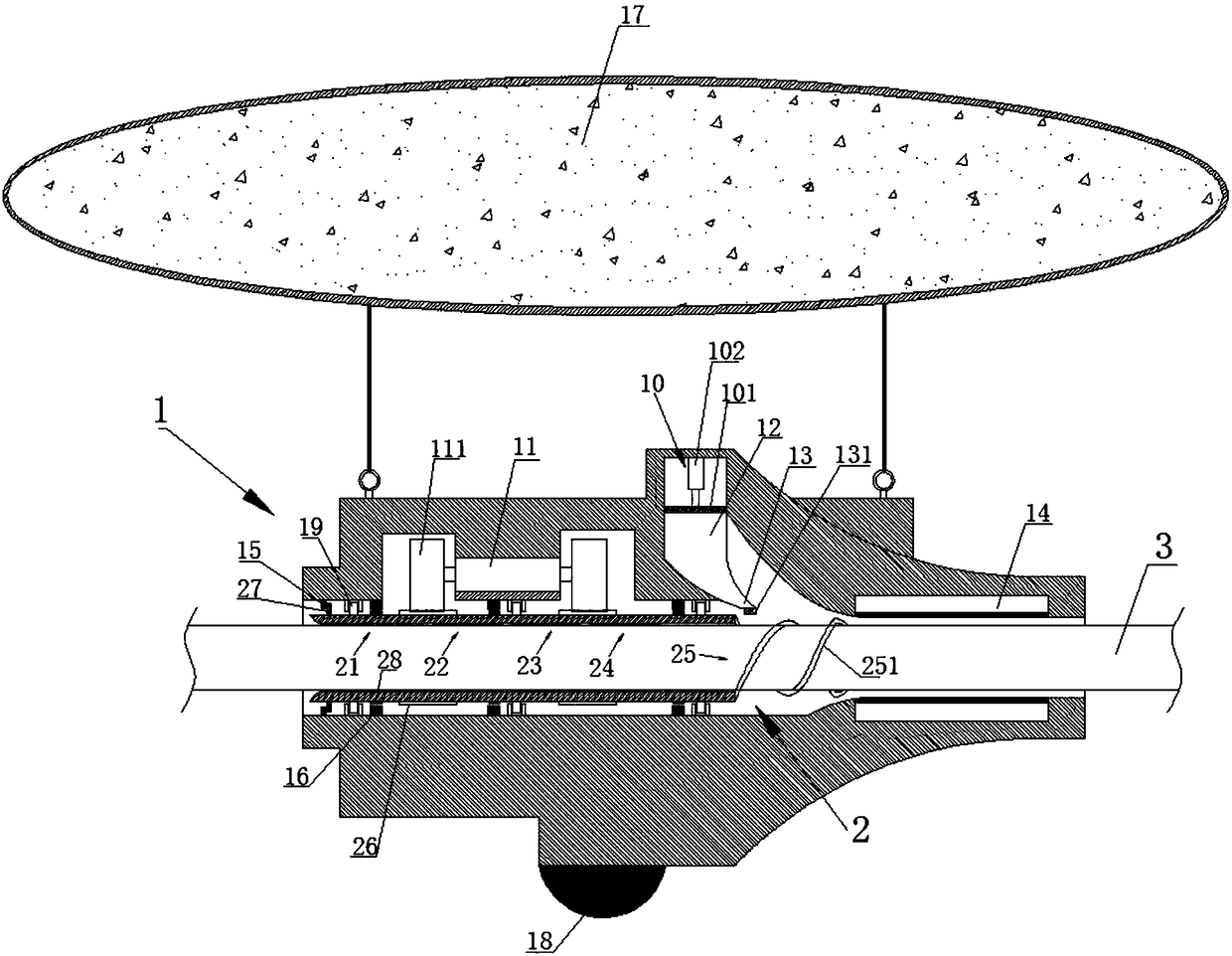

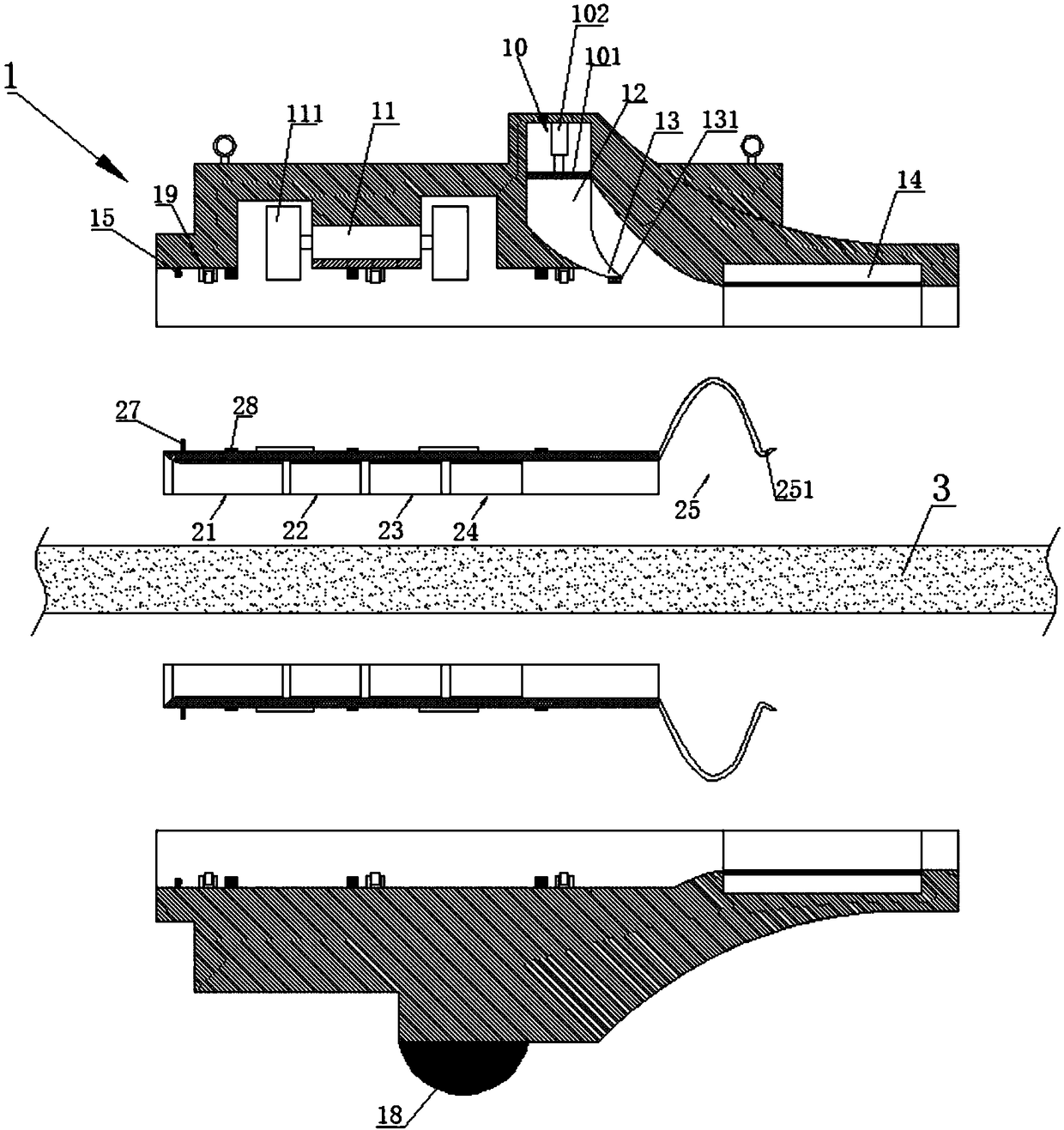

[0044] see figure 1 , figure 2, a repair device for high-altitude cable insulation aging, including a housing 1 and a swivel 2 rotatably sleeved in the housing 1; the swivel 2 is rotatably sleeved outside the high-altitude cable 3; the swivel 2 It is driven by a motor 11 fixedly installed in the casing 1 to rotate; the middle part of the casing 1 and above the high-altitude cable 3 is provided with a paint chamber 12; The paint filling port of the paint; the bottom of the paint chamber 12 is provided with a discharge port 13 facing the high-altitude cable 3; the discharge port 13 is provided with a solenoid valve 131 for opening and closing the discharge port 13; The waterproof insulating paint inside is extruded from the discharge port 13; the side of the swivel 2 in contact with the high-altitude cable 3 is sequentially arranged along its length direction to use the rotation of the swivel 2 to make the repair device advance along the high-altitude cable 3. Utilize the rot...

Embodiment 2

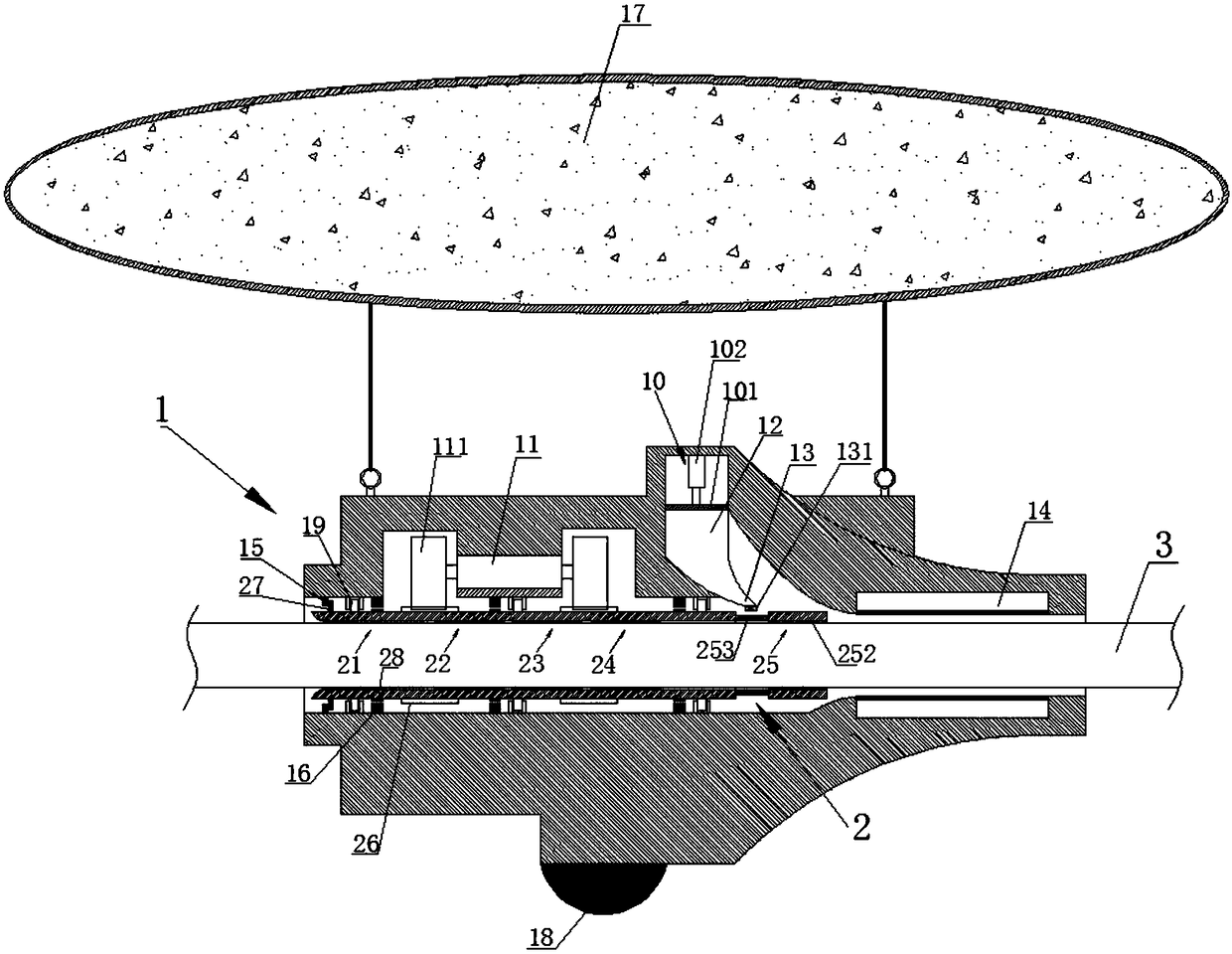

[0056] see image 3 , Figure 4 The difference between the second embodiment and the first embodiment is that the smoothing part 25 is cylindrical, and its inner surface is provided with a sponge layer 252 for evenly coating the paint on the high-altitude cable 3; the smoothing part 25 and the The fine grinding part 24 is set at intervals and connected by a plurality of connecting rods 253. The distance between the connecting rods 253 is set parallel to each other so that the waterproof insulating paint extruded from the discharge port 13 can fall to the high altitude through the gaps between the connecting rods 253. Cable 3 surface.

[0057] A method for repairing the aging of the insulating layer of high-altitude cables, using the repair device, including three steps: a repair device preparation process, a repair device installation process, and a repair process:

[0058] Preparation process:

[0059] Fill the paint cavity 12 with waterproof insulating paint from the pain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com