Power distribution line insulation wrapping device

A power distribution line and wrapping technology, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve problems such as unreasonable direction, tree branches being broken and connected to the line, line faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

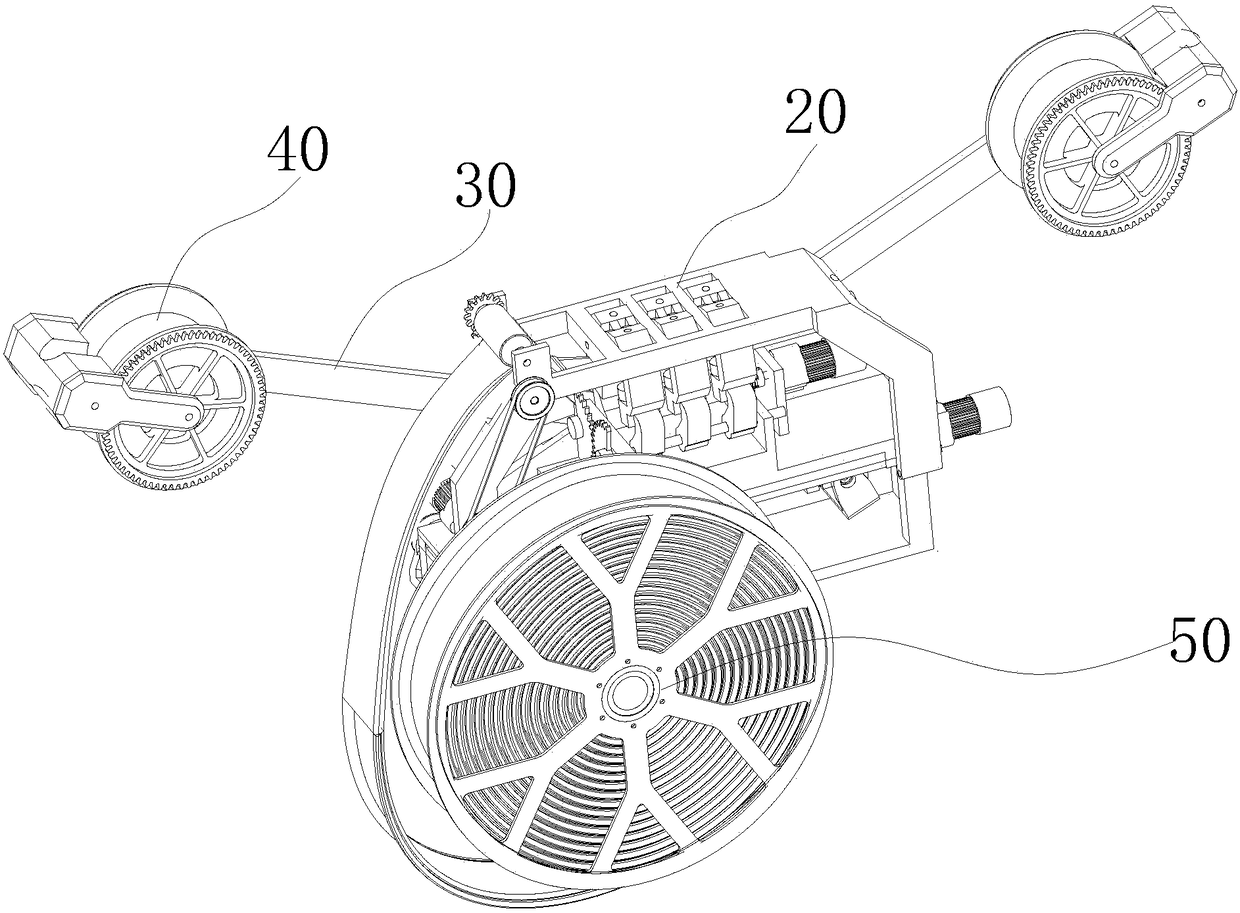

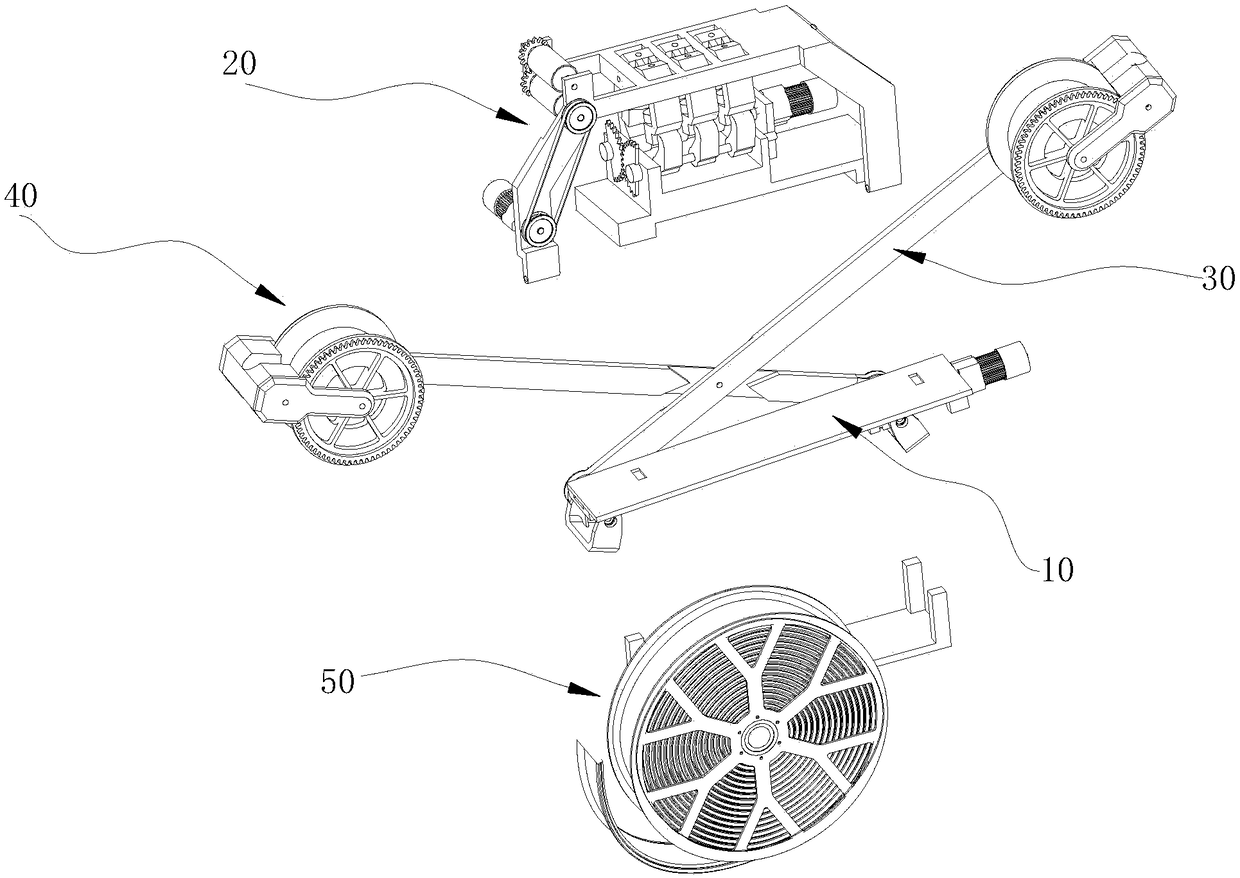

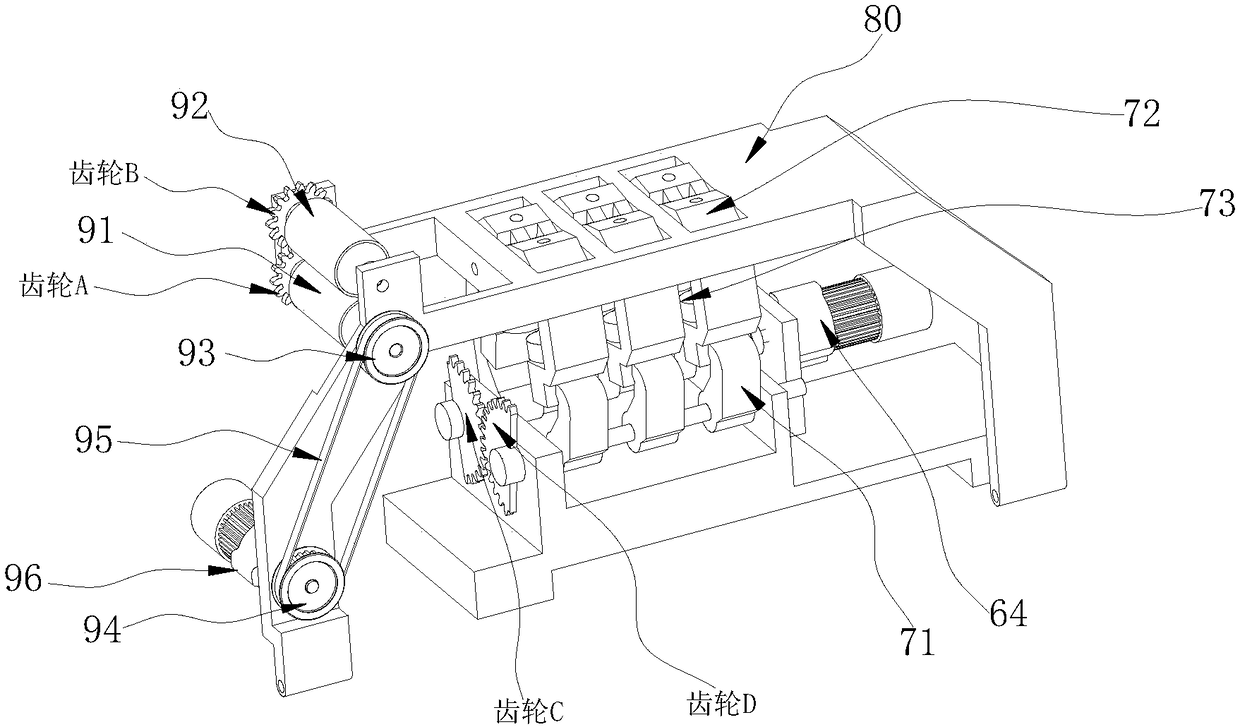

[0021] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a distribution line insulation wrapping device, including a distribution line wrapping mechanism 20 arranged on a support plate 10, one side of the support plate 10 is connected to one end of the lifting mechanism 30, and the lifting mechanism 30 The other end forms a sliding fit with the power distribution line to be wrapped through the walking mechanism 40. The wrapping mechanism 20 includes a transmission structure and a clamping structure. One end of the transmission structure is connected to the discharge port of the wrapping belt of the feeding tray 50, and the other end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com