Cable repair device and cable repair method

A cable and repair glue technology, which is applied in the direction of insulation/armored cable repair equipment, etc., can solve problems such as water ingress, potential safety hazards of cables, and insulation performance degradation, and achieve good waterproof and moisture-proof performance, strong strength, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

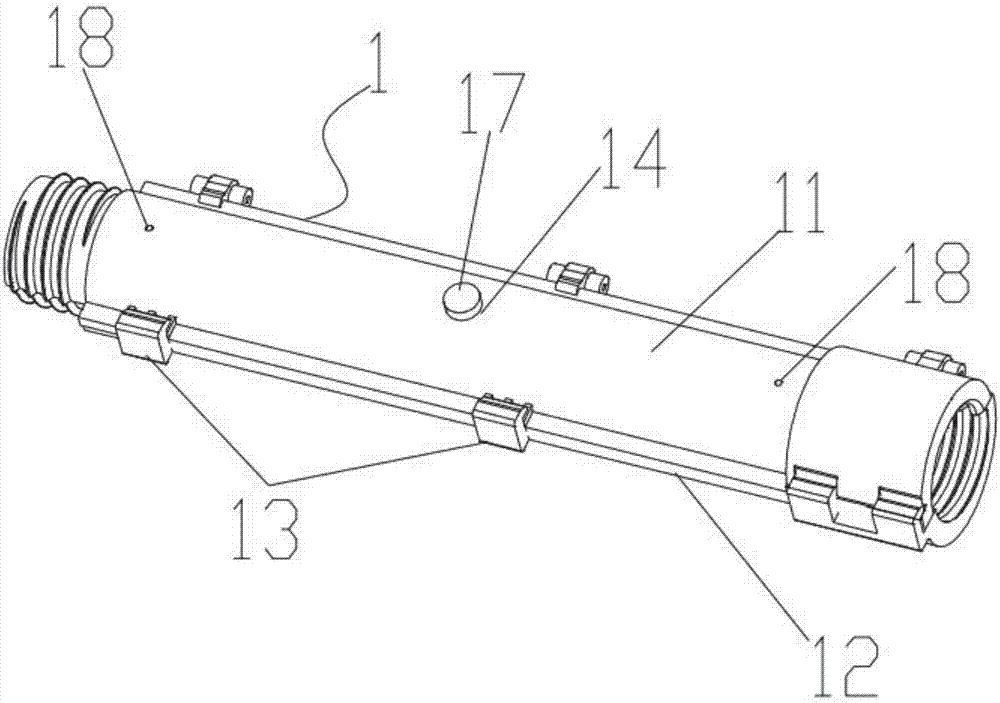

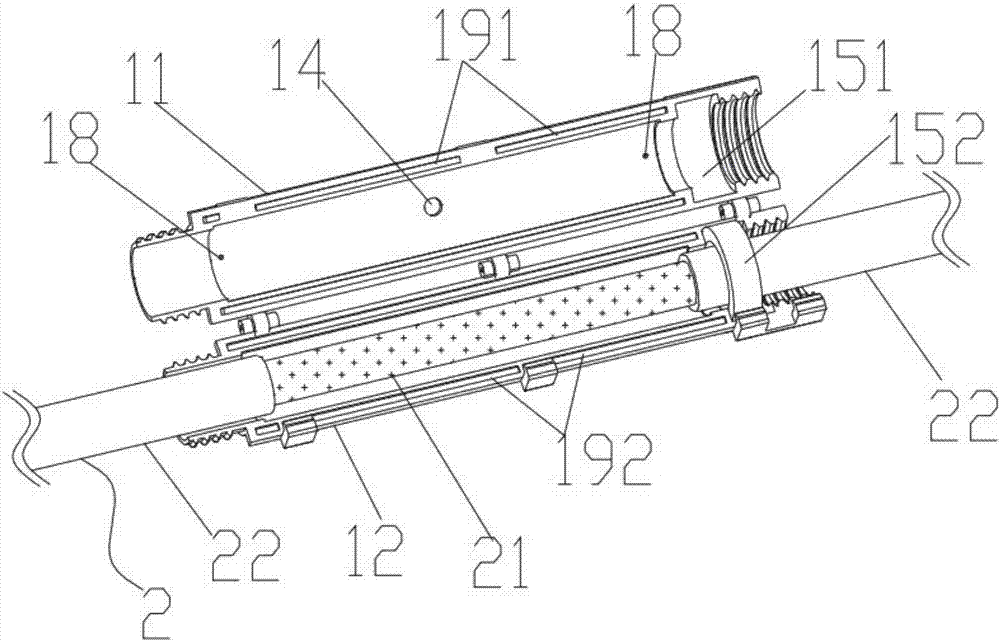

[0029] like Figure 1-2 As shown, a cable repair device includes a repair shell 1, the repair shell 1 is a combined structure, including two sub-shells 11, 12, one adjacent side of the two sub-shells 11, 12 is hinged, and the other is adjacent The sides can be connected by a locking device, wherein the sub-shell 11 is provided with a glue injection hole 14, and the repair shell 1 is a mating structure, which is convenient to be applied to the continuously extending cables that have been erected; the repair shell 1 is combined to form two A cable passing cavity with an open end, the inner diameter of the passing cavity is larger than the outer diameter of the cable to be repaired, when in use, the cable 2 passes through the passing cavity in the repaired shell 1, and the repaired shell 1 covers the damaged cable sheath 21 Covered inside, the two ends of the repair shell 1 are respectively set on the cable insulation sheath 22 at the two ends of the damaged cable sheath 21 and s...

Embodiment 2

[0038] On the basis of the technical solution of embodiment 1, the cable repairing device has been further improved:

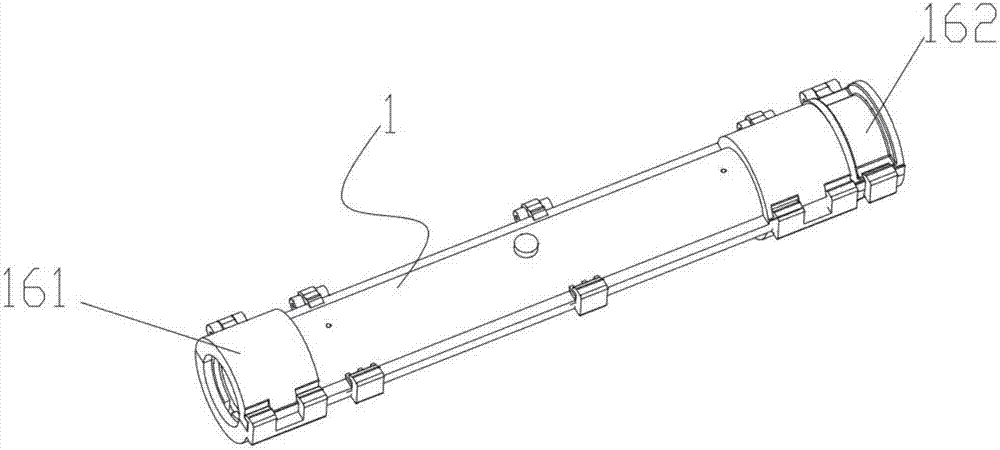

[0039] like Figure 3-5As shown, the cable repair device also includes two sealed end shells 161, 162, each end face of which is provided with a cable opening, and the two sealed end shells 161, 162 are all combined structures, wherein the sealed end shells The outer periphery of the shell 161 is provided with an external thread that matches the internal thread of the repair shell 1, and the inner periphery of the sealing end shell 162 is provided with an internal thread that matches the external thread of the repair shell 1, wherein the inner periphery of the sealing end shell 162 is A second slot 153 is also provided, and a second elastic rubber sleeve 154 is embedded in the second slot 153. The second elastic rubber sleeve 154 includes two semi-annular second rubber blocks corresponding to the closed structure of the sealed end shell. When the end shells a...

Embodiment 3

[0041] A kind of cable repairing method, adopts the cable repairing device in embodiment 1, comprises the following steps:

[0042] ① Cover the repaired shell 1 on the damaged cable sheath 21, and seal the two ends of the repaired shell 1 with the cable insulating sheath 22 at both ends of the damaged cable sheath 21;

[0043] ②Inject liquid repair glue into the cavity between the repair shell 1 and the damaged cable sheath 21 through the glue injection hole 14 until the cavity is filled with repair glue;

[0044] ③ The liquid repair glue in the cavity is solidified into a solid repair glue, which together with the repair shell 1 constitutes the repair layer of the damaged cable sheath 21 .

[0045] In this method, the damaged cable sheath 21 is covered by the repairing shell 1, and liquid repair glue is injected into the repairing shell 1. After the repairing glue is solidified, the repairing layer of the damaged cable sheath 21 is formed together with the repairing shell 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com