Device and method for inhibiting generation of hydrates in shaft through automatic early warning and heating

A technology for hydrate generation and automatic early warning, which is used in isolation devices, earth-moving drilling, wellbore/well components, etc. to ensure long-term effective operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical solutions, purposes and effects of the present invention, the technical solutions in the embodiments of the present invention are now clearly and completely described in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention. rather than all examples. Well-known methods, procedures, procedures, components and circuits have not been described in detail in order to avoid obscuring the essence of the present invention.

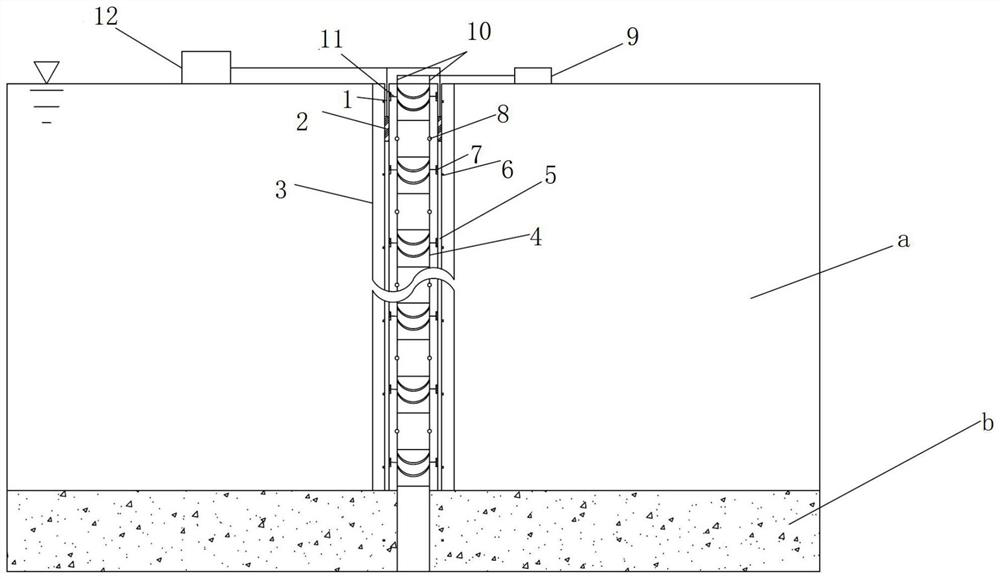

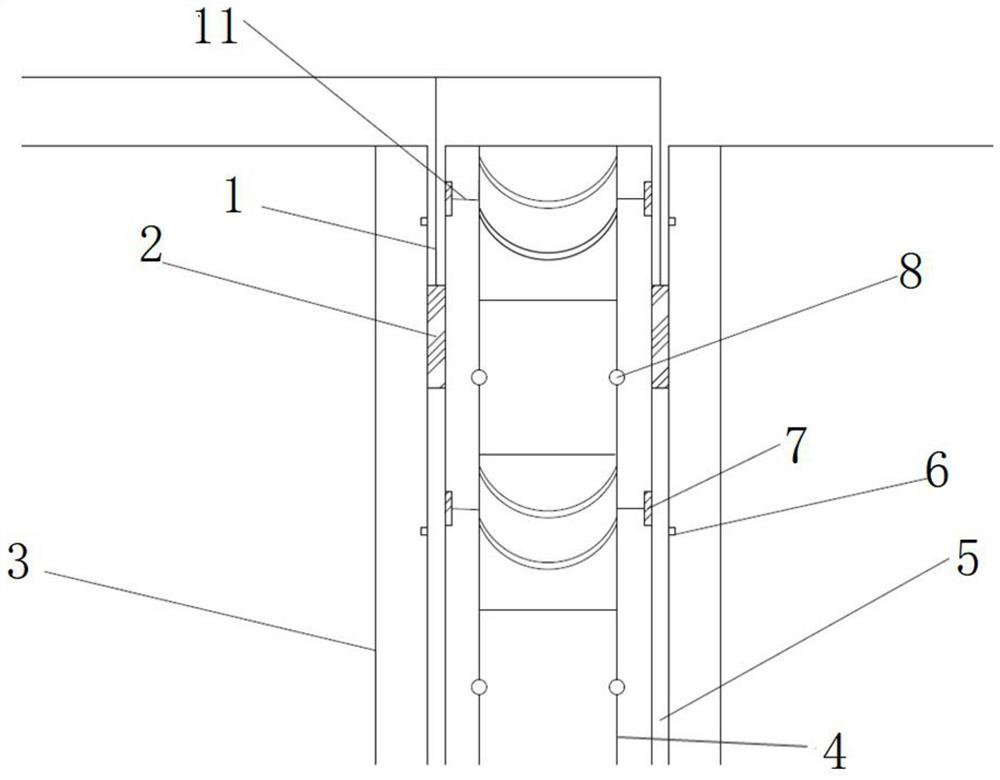

[0026] Such as figure 1 with figure 2 As shown, a device for automatic early warning and heating to suppress wellbore hydrate formation includes a first cable 1, an electrode 2, a water riser 3, an oil pipe 4, a chute 5, a card slot 6, a conductive metal sheet 7, a temperature and pressure sensor 8, Temperature and pressure indicating instrument 9 , second cable 10 , resistance wire 11 and motor 12 .

[0027] In the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com