Hot-melt type cable middle connection mounting technology

An installation process and cable technology, applied in the direction of connection/termination cable equipment, insulation/armored cable repair equipment, etc., can solve the problems of low efficiency of cable repair and connection, cumbersome and complicated tools, and high-tech participation. Achieve rapid and complete penetration, large flow capacity, and speed up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

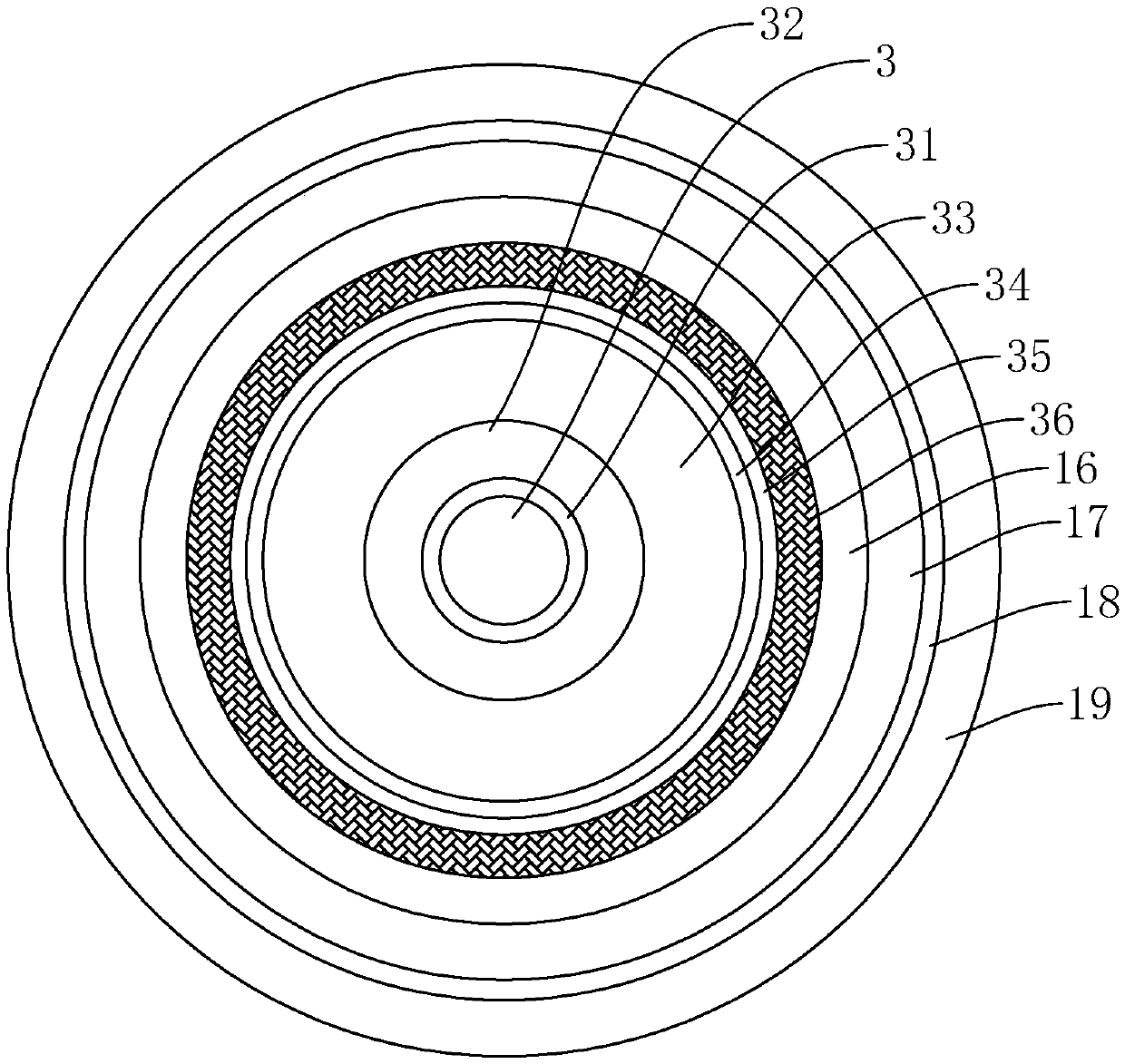

[0050] refer to Figure 2-5 , a heat-melt cable intermediate connection installation process disclosed by the present invention, comprising the following steps:

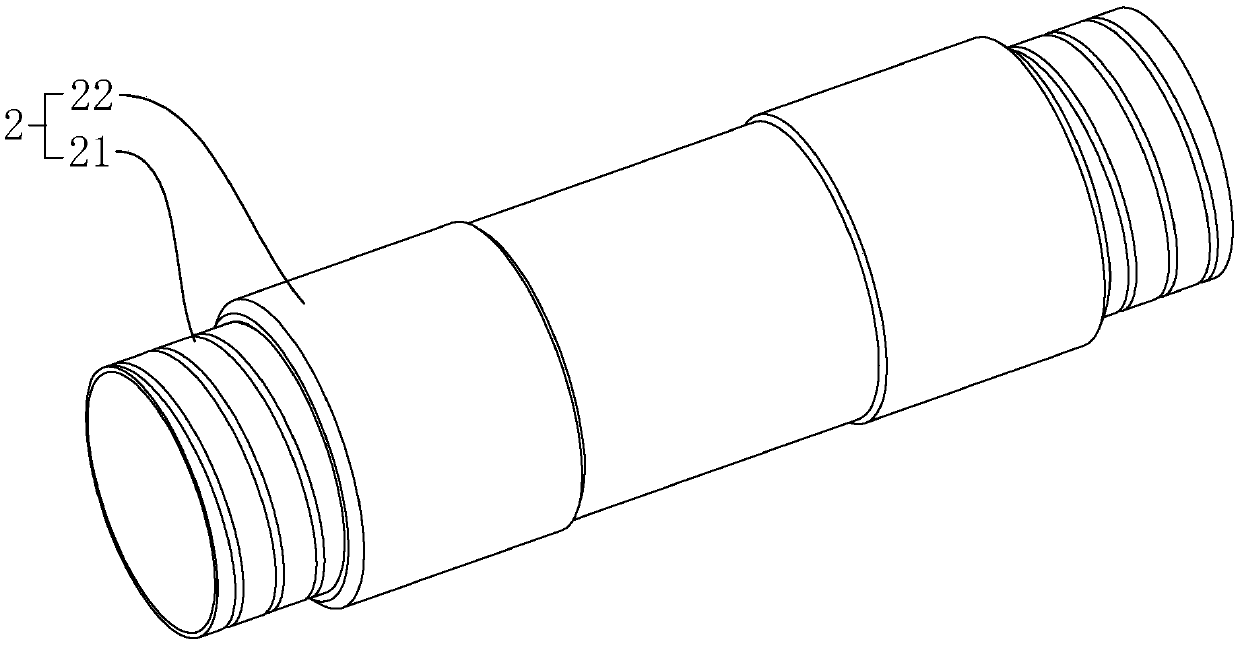

[0051] S1. Cable pretreatment: Prepare the cold shrinkable sleeve 2. The cold shrinkable sleeve 2 includes a sleeve 22 made of silicone rubber or ethylene propylene rubber. The sleeve 22 is pre-expanded to a core rope 21 that can be drawn out. The rope 21 is a support tube made of spiral plastic strips. The cold-shrinkable sleeve 2 can be the cold-shrinkable sleeve 2 manufactured by Wujiang Huading Heat-shrinkable Products Company.

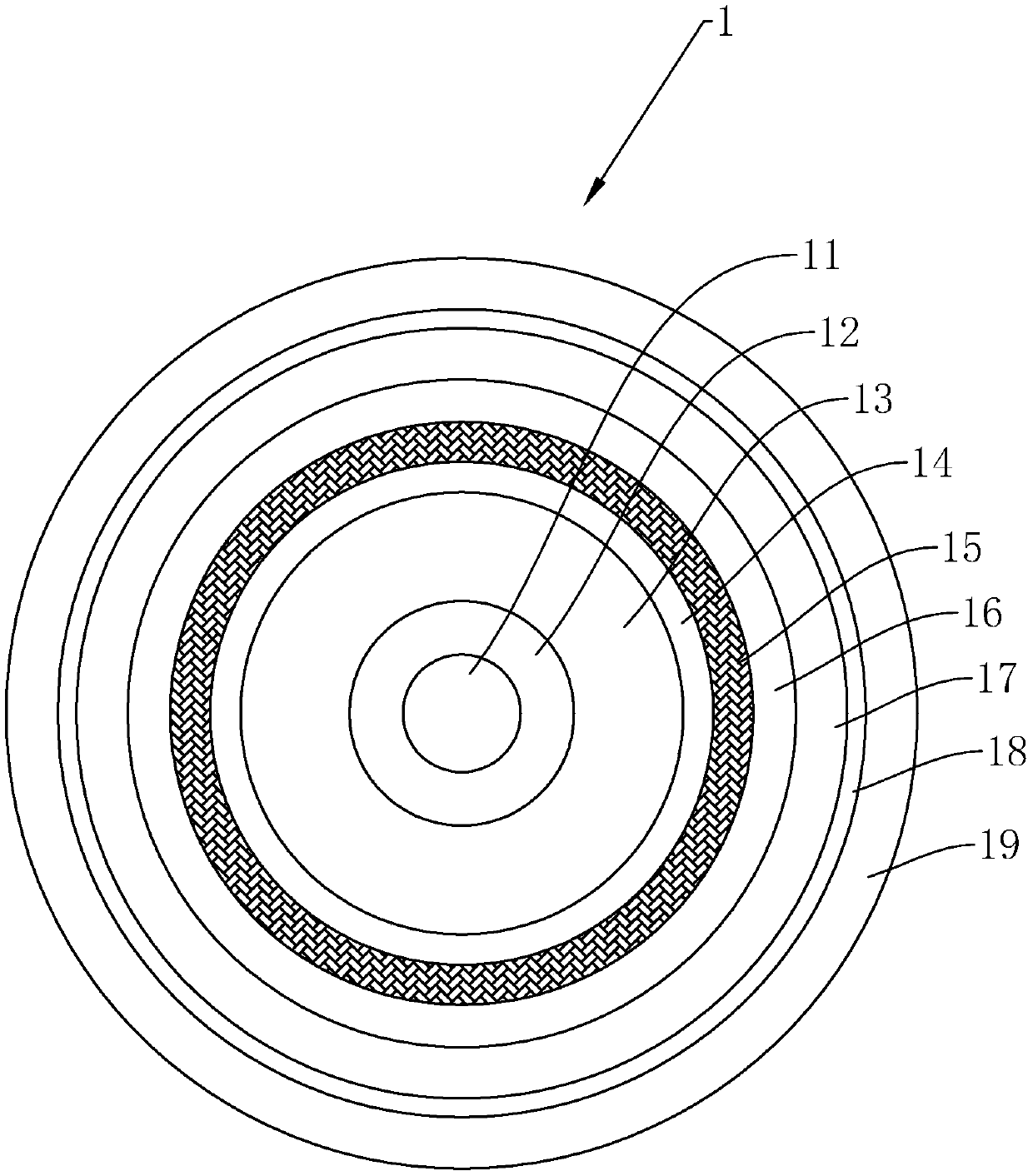

[0052] First put the cold shrinkable sleeve 2 on one of the cable main bodies 1, peel off the ends of the two cable main bodies 1 to be connected, expose the inner conductor 11 and the inner semiconductive layer 12 covering the conductor 11, and clean it with Towel for cleaning, the conductor 11 of the cable main body 1 used in this embodiment is a copper core.

[0053] S2. Conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com